On-line detection system and method for particle size distribution of ultrafine modal particles in high temperature flue gas

A technology of high-temperature flue gas and particle size distribution, which is applied in the directions of particle and sedimentation analysis, particle size analysis, and material analysis, etc., can solve the problem of sampling device burning out, and achieve the effect of improving accuracy and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

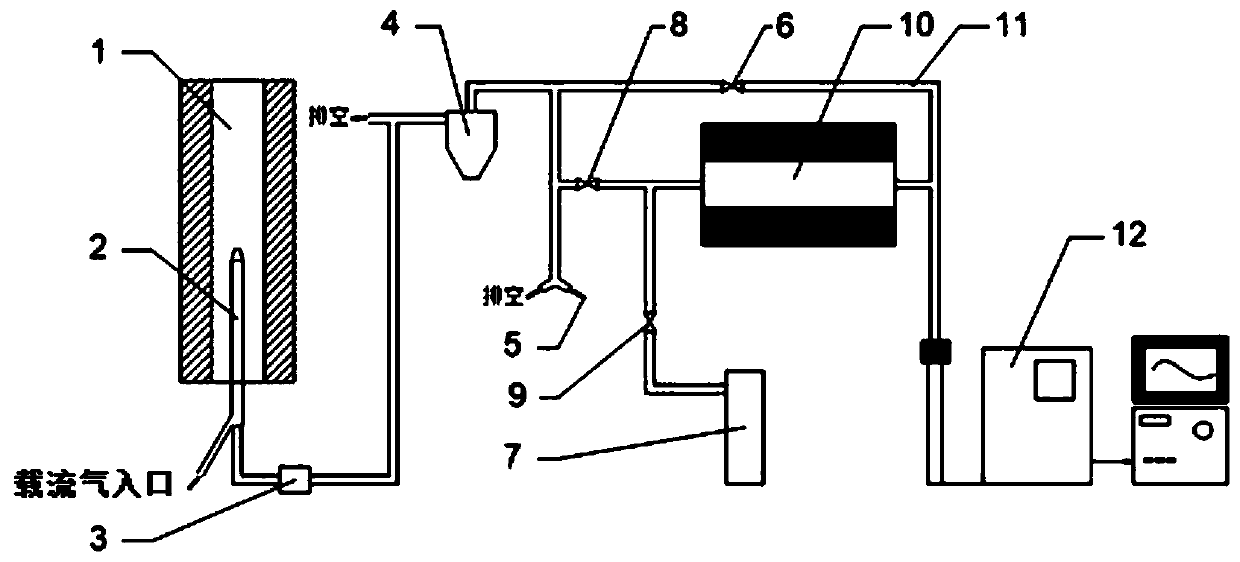

[0037] In the embodiment of the present invention, the PM cutter can also be replaced by other particle size selection devices 4, such as a cyclone separation device or an incoming flow impact separator. At the same time, according to the change of the research object range, the particle size selection with different selection effects can be replaced. Device 4 to obtain particulate matter in different particle size ranges.

[0038] The outlet of the PM cutter is connected to the inlet of the horizontal furnace 10, and the function of the horizontal furnace 10 is to oxidize the soot generated by combustion in the flue gas into CO 2 , completely remove the soot particles entrained in the particles in the flue gas, and leave the particles of mineral ash that cannot be removed by combustion.

[0039] During the detection process, the horizontal furnace 10 keeps the temperature constant, and the temperature must be guaranteed not to be lower than 800 degrees Celsius. After passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com