Device and method for rapid fog dispersal and thermal-cold transformation in leaching dewatering of high-temperature and high-humidity biomass

A high-temperature, high-humidity, cold-to-heat conversion technology, applied in the field of resource utilization of waste biomass, can solve the problems of workshop buildings and equipment corrosion, affecting normal operations, low visibility, etc., and achieves the effect of convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

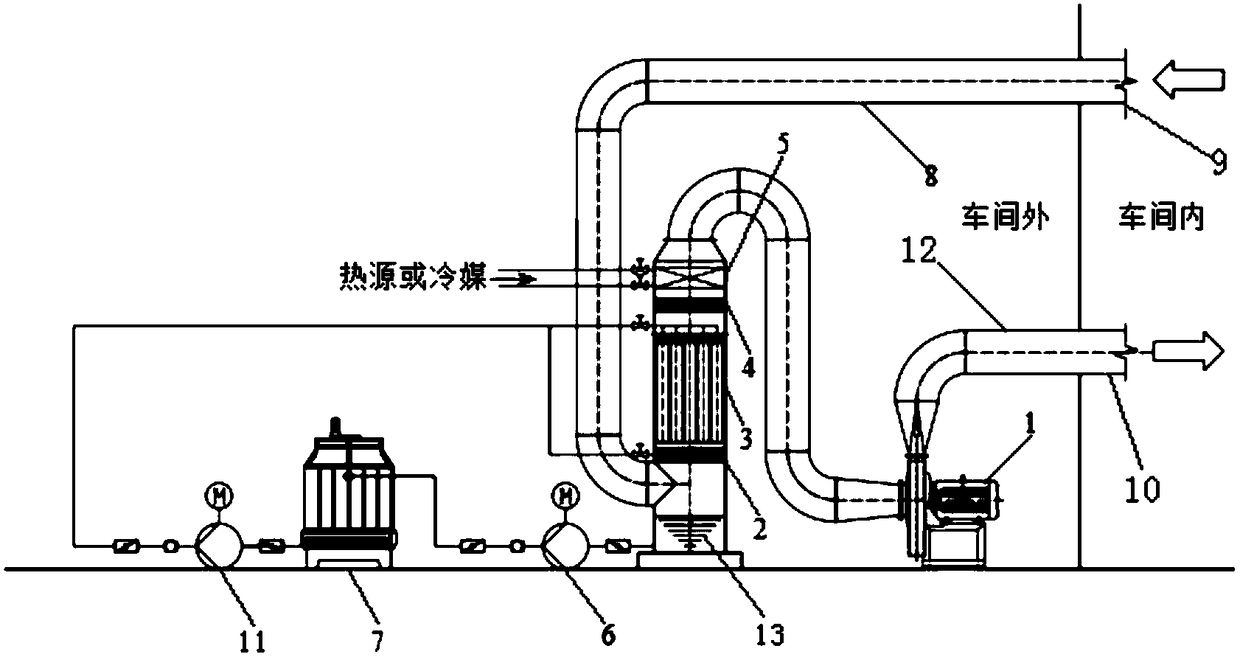

[0043] Such as figure 1 As shown, a device for quickly eliminating fog and switching between cold and heat during leaching and dehydration of high-temperature and high-humidity biomass, including induced draft fan 1, 2 water curtain injectors, 3-tube bundle demister, wire mesh demister 4, replacement Heater 5, first water pump 6, cooling tower 7, air inlet pipe 8, air suction port 9, air outlet 10, second water pump 11, air outlet pipe 12, sump 13.

[0044] The water curtain injector 2, the tube bundle demister 3, the wire mesh demister 4, and the heat exchanger 5 are integrated and installed in a tower body from bottom to top, and the bottom of the tower body passes through the air inlet pipe 8 and the air suction port. 9 communicates, and after the induced draft fan 1 at the top of the tower body, it communicates with the exhaust outlet 10 through the air outlet duct 12 .

[0045] The connecting end of the air inlet duct 8 and the workshop forms a plurality of branches, and...

Embodiment 2

[0051] A method for quickly eliminating fog and cooling when utilizing the device described in Example 1 to carry out high-temperature and high-humidity biomass leaching and dehydration, comprising the following steps:

[0052] (1) Firstly, the water vapor during the leaching and dehydration of the high-temperature and high-humidity biomass in the workshop is initially cooled and dehumidified through the water curtain formed by the water curtain injector 2; the water injected by the water curtain injector 2 is concentrated in the sump 13 In, then cool down by the cooling tower 7, re-enter the water curtain ejector 2 after cooling, and recycle;

[0053] (2) The water vapor passes through the tube bundle demister 3 and the wire mesh demister 4 successively to remove small-sized droplets and water foam in the water vapor to obtain dry gas;

[0054] (3) The temperature of the dry gas is further lowered through the heat exchanger 5, and the cooled gas enters the workshop.

[0055]...

Embodiment 3

[0059] A method for quickly eliminating fog and heating up when utilizing the device described in Example 1 to carry out high-temperature and high-humidity biomass leaching and dehydration, comprising the steps of:

[0060] (1) First, close the water curtain injector 2, and pass the water vapor during the leaching and dehydration of the high-temperature and high-humidity biomass in the workshop through the tube bundle demister 3 and the wire mesh demister 4 in order to remove the small-sized mist in the water vapor Drops and foam to get dry gas;

[0061] (2) The temperature of the dry gas is further raised through the heat exchanger 5, and the gas enters the workshop after the temperature rise.

[0062] In step (1), the inclination angle of the blades in the tube bundle demister is 30°.

[0063] In step (2), the temperature of the drying gas passing through the heat exchanger is >20° C. and the humidity is <50% RH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com