A kind of agricultural thin-walled microdropper and its manufacturing method

A micro-droplet and thin-walled technology, applied in botany equipment and methods, agriculture, application, etc., can solve the problems of unfavorable agricultural cost, unfavorable popularization and application, and increased maintenance cost, so as to reduce the quality of finished products, eliminate static electricity accumulation, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

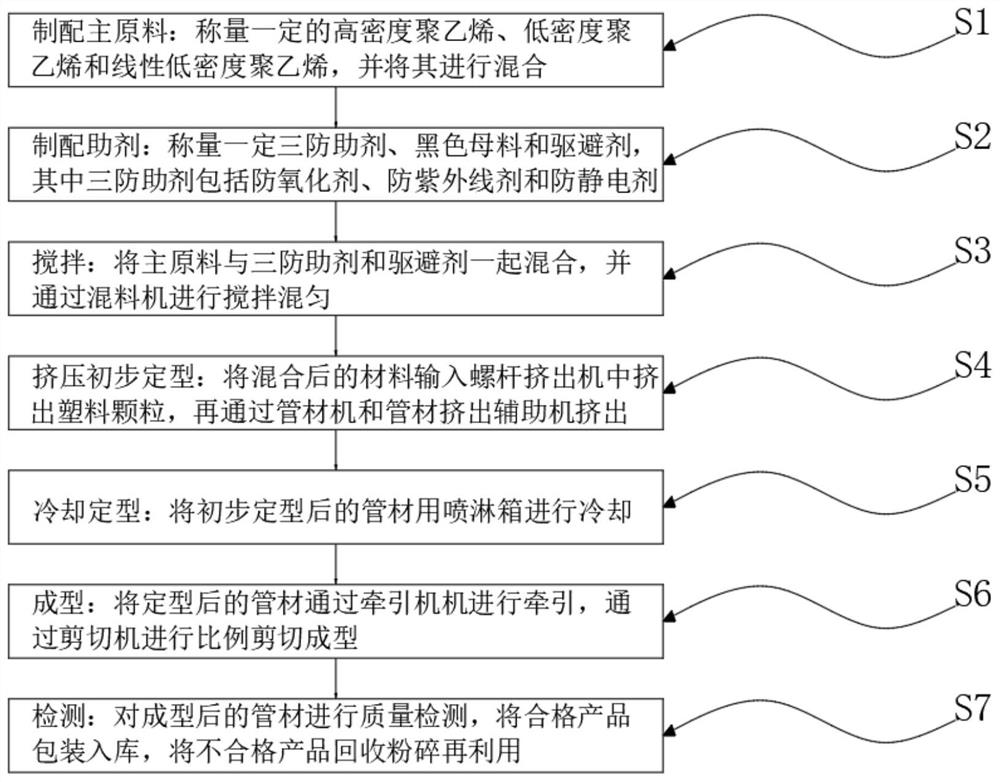

[0030] Embodiment 1: as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of agricultural thin-walled microdropper manufacturing method, comprises the steps:

[0031] S1. Preparation of main raw materials: Weigh certain high-density polyethylene, low-density polyethylene and linear low-density polyethylene, and mix them;

[0032] S2. Preparation of auxiliary agents: Weigh certain three-proof additives, black masterbatch and repellent, wherein the three-proof additives include anti-oxidant, anti-ultraviolet agent and antistatic agent;

[0033] S3. Stirring: mix the main raw materials with the three-proof additive and the repellent, and stir and mix with a mixer;

[0034] S4. Preliminary shaping of extrusion: input the mixed material into the screw extruder to extrude plastic particles, and then extrude through the pipe machine and pipe extrusion auxiliary machine;

[0035] S5. Cooling and setting: cooling the pipe after preliminary setting w...

Embodiment 2

[0043] Embodiment 2: as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of agricultural thin-walled microdropper manufacturing method, comprises the steps:

[0044] S1. Preparation of main raw materials: Weigh a certain amount of linear low density polyethylene and mix them;

[0045] S2. Preparation of auxiliary agents: Weigh certain three-proof additives, black masterbatch and repellent, wherein the three-proof additives include anti-oxidant, anti-ultraviolet agent and antistatic agent;

[0046] S3. Stirring: mix the main raw materials with the three-proof additive and the repellent, and stir and mix them evenly through a mixer;

[0047] S4. Preliminary shaping of extrusion: input the mixed material into the screw extruder to extrude plastic particles, and then extrude through the pipe machine and pipe extrusion auxiliary machine;

[0048] S5. Cooling and setting: cooling the pipe after preliminary setting with a spray box;

[0049] S6....

Embodiment 3

[0056] Embodiment 3: as figure 1 As shown, the present invention provides a kind of technical scheme, a kind of agricultural thin-walled microdropper manufacturing method, comprises the steps:

[0057] S1. Preparation of main raw materials: Weigh certain high-density polyethylene, low-density polyethylene and linear low-density polyethylene, and mix them;

[0058] S2. Preparation of auxiliary agents: Weigh certain three-proof additives, black masterbatch and repellent, wherein the three-proof additives include anti-oxidant and anti-ultraviolet agent;

[0059] S3. Stirring: mix the main raw materials with the three-proof additive and the repellent, and stir and mix them evenly through a mixer;

[0060] S4. Preliminary shaping of extrusion: input the mixed material into the screw extruder to extrude plastic particles, and then extrude through the pipe machine and pipe extrusion auxiliary machine;

[0061] S5. Cooling and setting: cooling the pipe after preliminary setting with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com