Nano flame retardant and thermal insulating insulation material

A technology of thermal insulation and thermal insulation materials, applied in the direction of coating, layered products, metal layered products, etc., can solve the problems of low strength, unsatisfactory air bubble heat insulation effect, unsatisfactory puncture resistance, and poor integrity, and achieve Excellent mechanical properties, increased strength, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

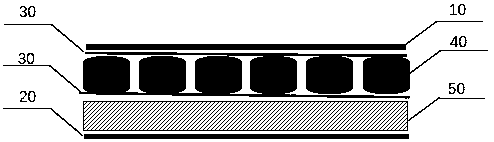

[0018] A nano flame-retardant thermal insulation material, characterized in that it includes a core nanocomposite thermal insulation material and a surface strengthening protective layer, wherein the nanocomposite thermal insulation material is a multilayer composite material based on a nano-airbag reflective layer, and the surface strengthening protection The layer includes a high-temperature surface and other protective surfaces except the high-temperature surface. The high-temperature surface is inorganic fiber cloth treated with flame-retardant treatment, and the remaining protective surfaces are inorganic fiber cloth treated with inorganic nano-sol.

[0019] The core nano-composite insulation material uses the airbag layer with evenly dense airbags as the first insulation layer, and the XPE material with closed-cell structure as the second insulation layer, and the two insulation layers are bonded by adhesive; It is sealed with high-reflection mirror aluminum foil, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com