Preparation method of a surface-enhanced high-temperature-resistant nano-insulation material

A nano-insulation material and surface strengthening technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

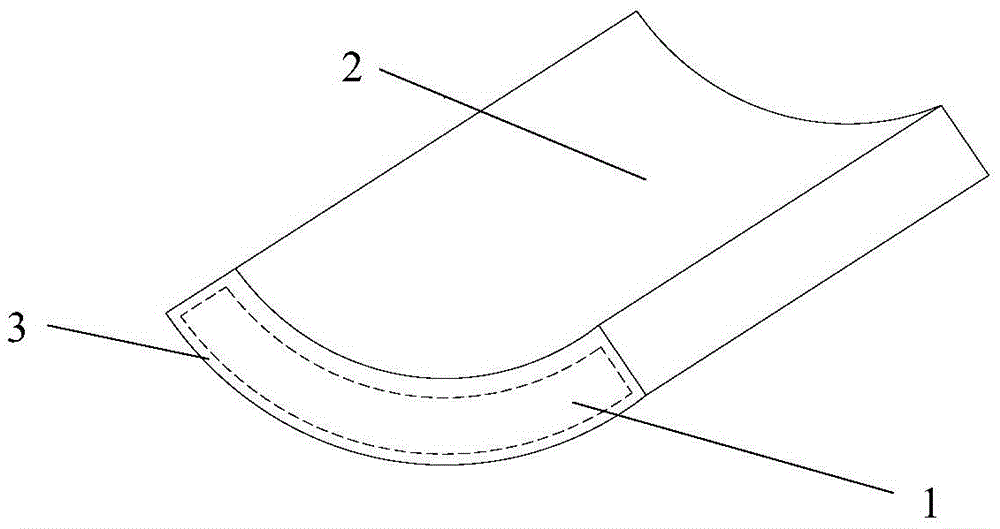

[0039] Such as figure 1 Shown is a schematic diagram of the surface-strengthened high-temperature-resistant nano-insulation material in Example 1 of the present invention. The high-temperature-resistant nano-insulation material to be prepared in this example is a part of a cylindrical structure, including an inner nano-insulation core material 1 And the surface reinforcement layer, the nano-insulation material is granular porous insulation material or fiber-reinforced airgel insulation material, the surface reinforcement layer includes a low-temperature surface 2 and other surfaces 3 except the low-temperature surface 2, wherein the low-temperature surface is inorganic The fiber cloth reinforces the resin, and the other sides are inorganic fiber cloth.

[0040] In this example:

[0041]The nano insulation material is compression molded SiO 2 Nanoparticle porous insulation material. Thickness is 30mm, density is 0.35g / cm 3 , the thermal conductivity is 0.023W / m·K.

[0042]...

Embodiment 2

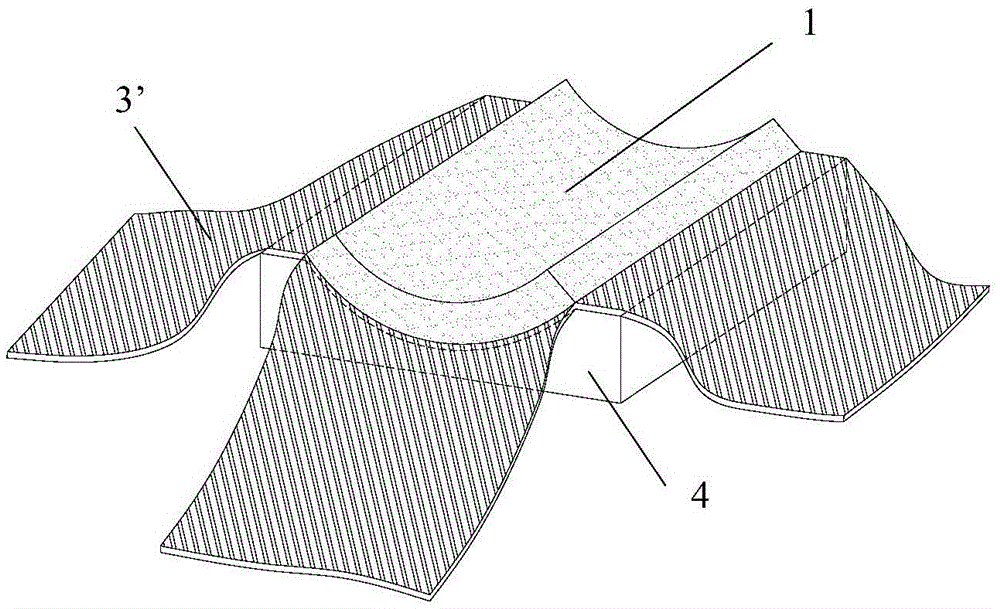

[0055] The shape of the surface-reinforced high-temperature-resistant nano-insulation material in this embodiment is the same as in Example 1, including the inner nano-insulation material core material 1 and the surface strengthening layer, and the nano-insulation material is a granular porous insulation material or fiber-reinforced airgel In the heat insulating material, the surface strengthening layer includes a low temperature surface 2 and other surfaces 3 except the low temperature surface 2, wherein the low temperature surface is made of inorganic fiber cloth reinforced resin, and the other surfaces are made of inorganic fiber cloth.

[0056] In this example:

[0057] Nano insulation material is mullite fiber reinforced SiO 2 Airgel composites. The thickness is 35mm and the density is 0.2g / cm 3 , the thermal conductivity is 0.021W / m·K.

[0058] The low-temperature surface 2 in the surface reinforcement layer is made of inorganic fiber cloth reinforced resin, and the o...

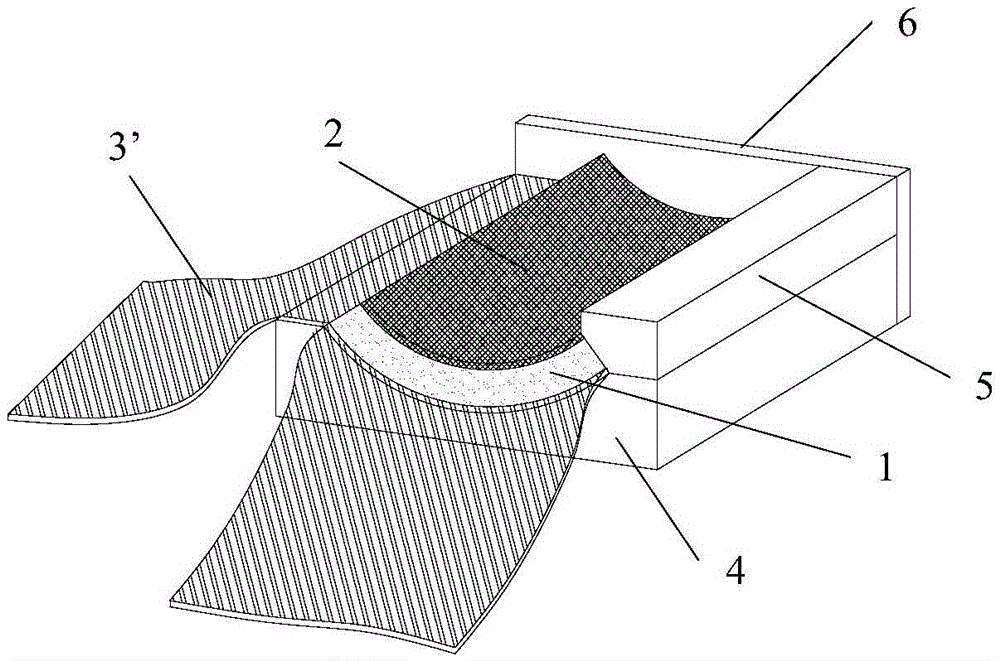

Embodiment 3

[0069] The shape of the surface-reinforced high-temperature-resistant nano-insulation material in this embodiment is the same as in Example 1, including the inner nano-insulation material core material 1 and the surface strengthening layer, and the nano-insulation material is a granular porous insulation material or fiber-reinforced airgel In the heat insulating material, the surface strengthening layer includes a low temperature surface 2 and other surfaces 3 except the low temperature surface 2, wherein the low temperature surface is made of inorganic fiber cloth reinforced resin, and the other surfaces are made of inorganic fiber cloth.

[0070] In this example:

[0071] The nano insulation material is compression molded Al 2 o 3 Nanoparticle porous insulation material. Thickness is 40mm, density is 0.45g / cm 3 , the thermal conductivity is 0.03W / m·K.

[0072] The low-temperature surface 2 in the surface reinforcement layer is made of inorganic fiber cloth reinforced res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com