A high-precision and high-efficiency shipbuilding steel plate information printing production line

A shipbuilding steel plate, high-efficiency technology, applied in printing, printing devices, copying/marking methods, etc., to achieve the effects of improving quality levels, cutting productivity, and reducing man-hours for writing and marking lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

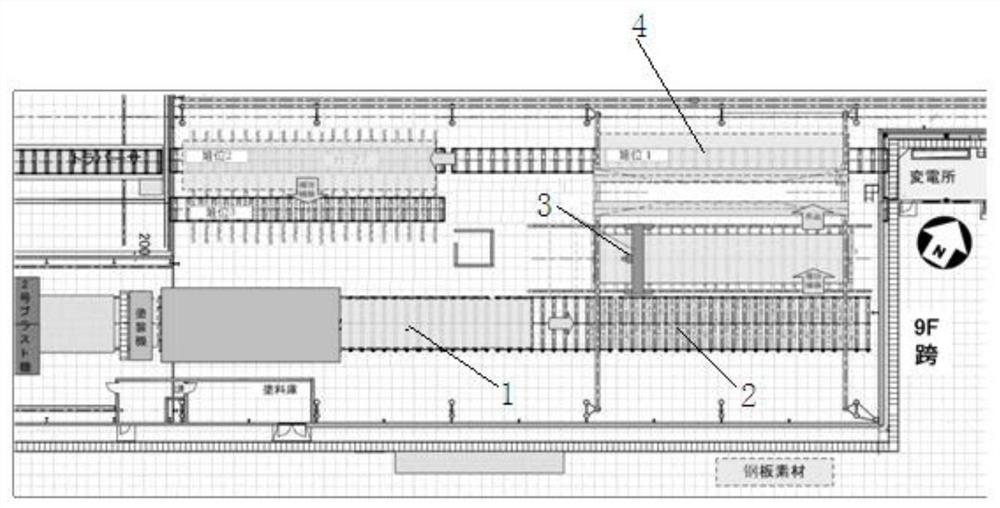

[0023] Such as figure 1 As shown, a high-precision and high-efficiency shipbuilding steel plate information printing production line includes the following steps: preprocessing → lateral movement and lifting → printing in the printing area → lifting → repeated operations; the specific operations are as follows:

[0024] (1) Pretreatment: the steel plate runs on the pretreatment roller table 1 Pretreatment: shot blasting and rust removal on the surface of the steel plate, primer spraying, the steel plate is automatically transported on the roller table, automatic shot blasting and painting equipment operations;

[0025] (2) Traverse lifting: the pretreatment track 1 is arranged in parallel with the comprehensive printing device 3, and the pretreated steel plate is lifted out from the pretreatment roller table through the steel plate traverse device 2;

[0026] (3) Printing in the printing area: put the steel plate lifted out by lateral movement into the full-scale printing devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com