Colored porous asphalt and manufacturing method thereof

A permeable asphalt and color technology, applied in the field of colored permeable asphalt and its preparation, can solve problems such as insufficient stability, and achieve the effects of improving color maintenance, enhancing stability, strengthening interaction and integrity

- Summary

- Abstract

- Description

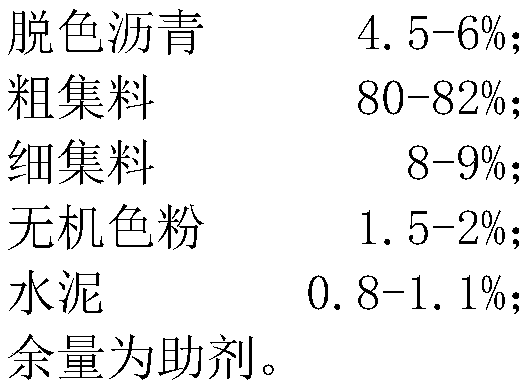

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

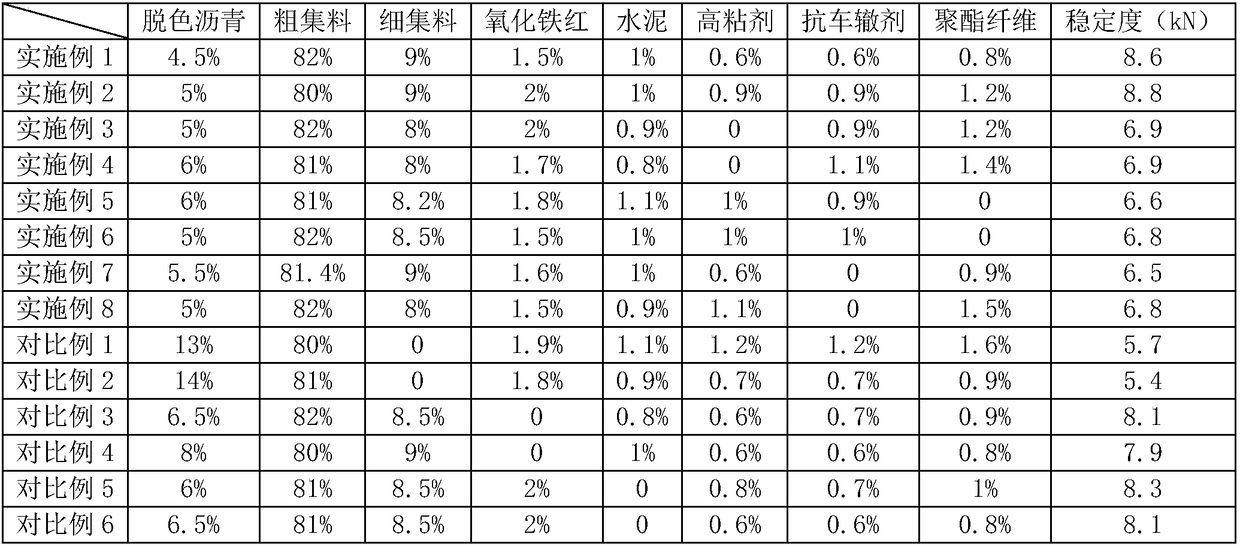

[0048] Example 1, a colored permeable asphalt, the raw material components are shown in Table 1 by mass percentage. The colored permeable asphalt is prepared through the following steps:

[0049] Step 1, heat the coarse and fine aggregates to 190°C and add them into the mixing tank, then put in the anti-rutting agent (KZD-I-K) and polyester fiber (Yancheng Baosilong Engineering Fiber Technology Co., Ltd., 6mm) , stirring for 10s, each material is evenly mixed in the mixing tank and the mixing tank is preheated;

[0050] Step 2: Add high-viscosity agent (Shenzhen Haichuan New Material Technology Co., Ltd., SINOTPS) and decolorized asphalt (Foshan Fangxiang Chemical Co., Ltd., 0# hydrogenated petroleum resin) heated to 175°C in the mixing tank, and continue mixing 70s;

[0051] Step 3, add cement (42.5R Portland cement) and red iron oxide into the mixing tank, and mix for 130s;

[0052] Step 4, discharge.

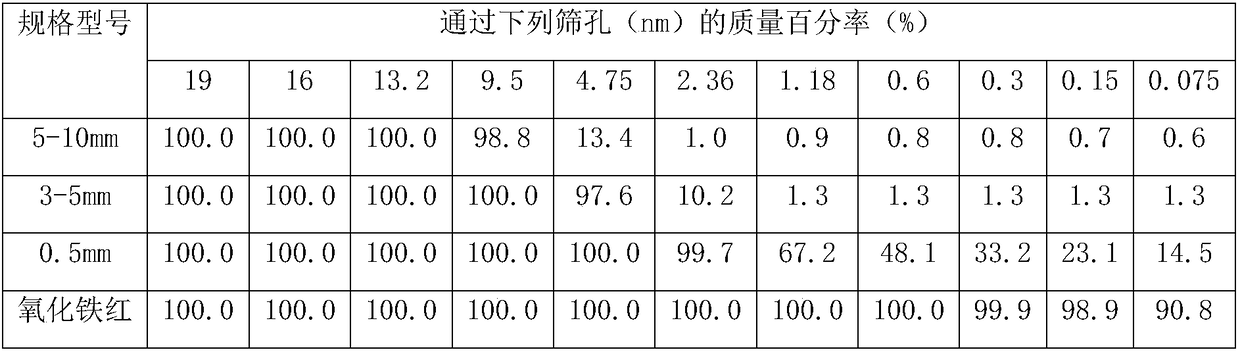

[0053] Among them, the coarse aggregate is clean, dry, and rough-sur...

Embodiment 2

[0055] Embodiment 2 is different from Embodiment 1 in that, by mass percentage, the raw material components are as shown in Table 1.

Embodiment 3

[0056] Embodiment 3 differs from Embodiment 1 in that, by mass percentage, the raw material components are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com