A lanthanide MOF spun fiber membrane as a sensor for detecting uric acid and its preparation

A fiber membrane and uric acid technology, applied in rayon manufacturing, fiber chemical characteristics, instruments, etc., can solve problems such as limited sensitivity and complex instruments, and achieve high sensitivity, wide pH detection range, high selectivity and excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] 1. Preparation of sodium terephthalate brine solution

[0046] Ligand terephthalic acid (referred to as H 2 BDC or PTA) is converted into a water-soluble sodium carboxylic acid salt, and then the sodium carboxylic acid salt ligand and the rare earth center can be used for rapid polymerization in aqueous solution.

[0047]Preparation method: take 1.667g (10mmol) terephthalic acid, add it into 100mL 0.2mol / L sodium hydroxide aqueous solution under stirring, stir at room temperature until the solution is clear, that is, 0.1mol / L sodium terephthalic acid aqueous solution , Reaction equation: 2NaOH+H 2 BDC→Na 2 BDC+2H 2 O.

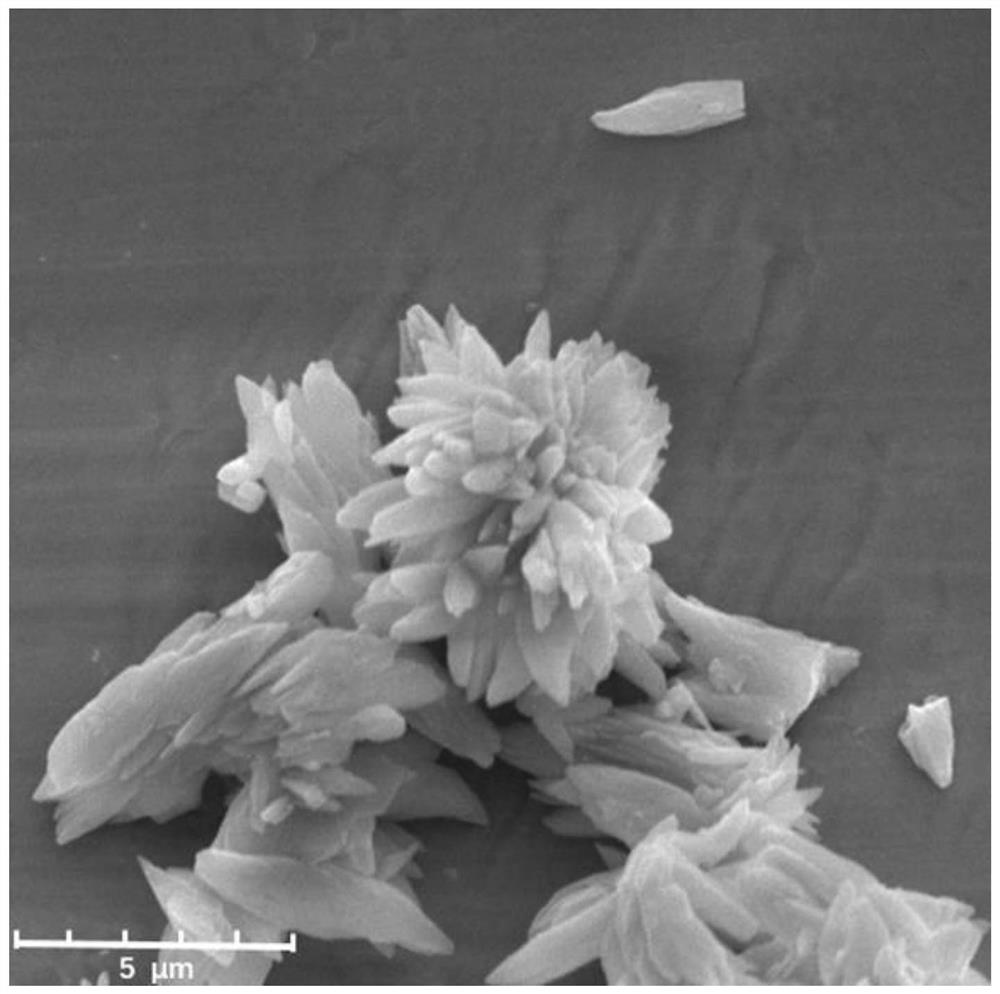

[0048] 2. Synthesis of Eu-PTA-MOF

[0049] Rapid polymerization in aqueous solution with rare earth elements and sodium terephthalate as basic building blocks.

[0050] Preparation method: Weigh 0.2 mmol europium(III) chloride hexahydrate (EuCl 3 ·6H 2 O) Dissolve in 14mL aqueous solution, stir slowly at room temperature and drop 0.1mol / L Na 2 B...

Embodiment 1

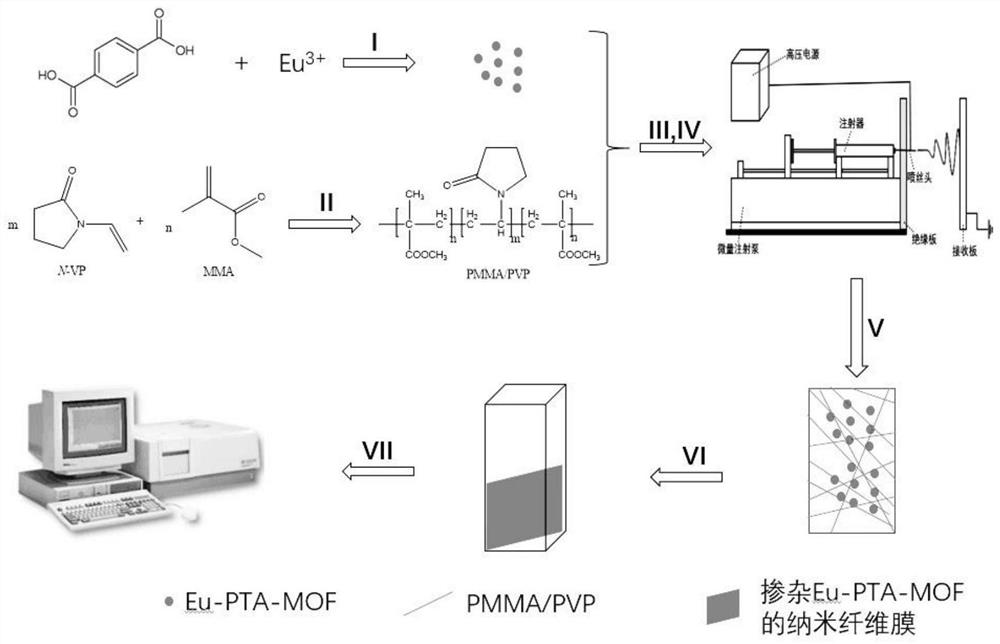

[0057] Preparation of Electrospun Fibrous Membranes Containing Lanthanide Metal-Organic Frameworks

[0058] Preparation of electrospinning solution: weigh 10 mg of Eu-PTA-MOF powder at room temperature, add 2 mL of tetrahydrofuran (THF) / N-methylpyrrolidone (NMP) (3 / 1, v / v) mixed solution to it , Stir at a constant temperature of 30°C until the powder is evenly dispersed, and then ultrasonic for half an hour. Then, a certain amount (accounting for 20% of the mass of the THF / NMP mixture) of the copolymer PMMA / PVP solid was added, and the mixture was stirred at a constant temperature of 30° C. for 4 hours to obtain a milky white suspension solution. It is worth noting that PMMA / PVP is a polymer material, which requires a certain temperature and stirring time during the dissolution process, and the temperature should not be too high, otherwise part of the solvent will volatilize.

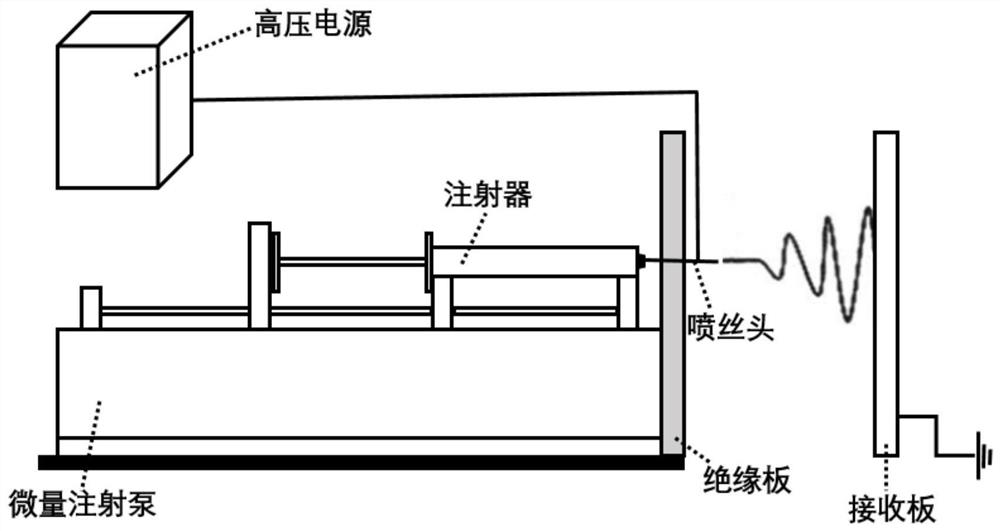

[0059] Electrospinning: Since the concentration of spinning solution, electrospinning rate, voltage...

Embodiment 2

[0061] Electrospun fiber membrane anti-interference test

[0062] Due to the presence of other primary metabolites in human urine, such as co-excreted products such as creatinine, creatine, urea, etc., the selectivity of electrospun fibrous membranes containing lanthanide MOFs is critical. In order to investigate the selectivity of electrospun fibrous membranes containing lanthanide metal-organic frameworks for the detection of uric acid, we selected interfering substances including water (H 2 O), Creatinine, Creatine, Urea, SO 4 2- , Na + , K + , NH 4 + , Cl - and Glucose. The aqueous solution of each interfering substance is mixed with uric acid solution (concentration is 0.5mmol / L), joins in the cuvette, then inserts the electrospun fiber membrane prepared in embodiment 1 in the cuvette, and records the fibrous membrane Luminescence spectrum. The influence of various interfering substances in urine on the selectivity of uric acid detected by electrospun fiber membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com