Plate structure multi-defect detection method based on DBSCAN and k-means algorithm

A defect detection and algorithm technology, applied in measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, to achieve the effects of reducing manual intervention, high engineering application value, and eliminating external noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given, but the protection scope of the present invention is not limited to the following embodiments.

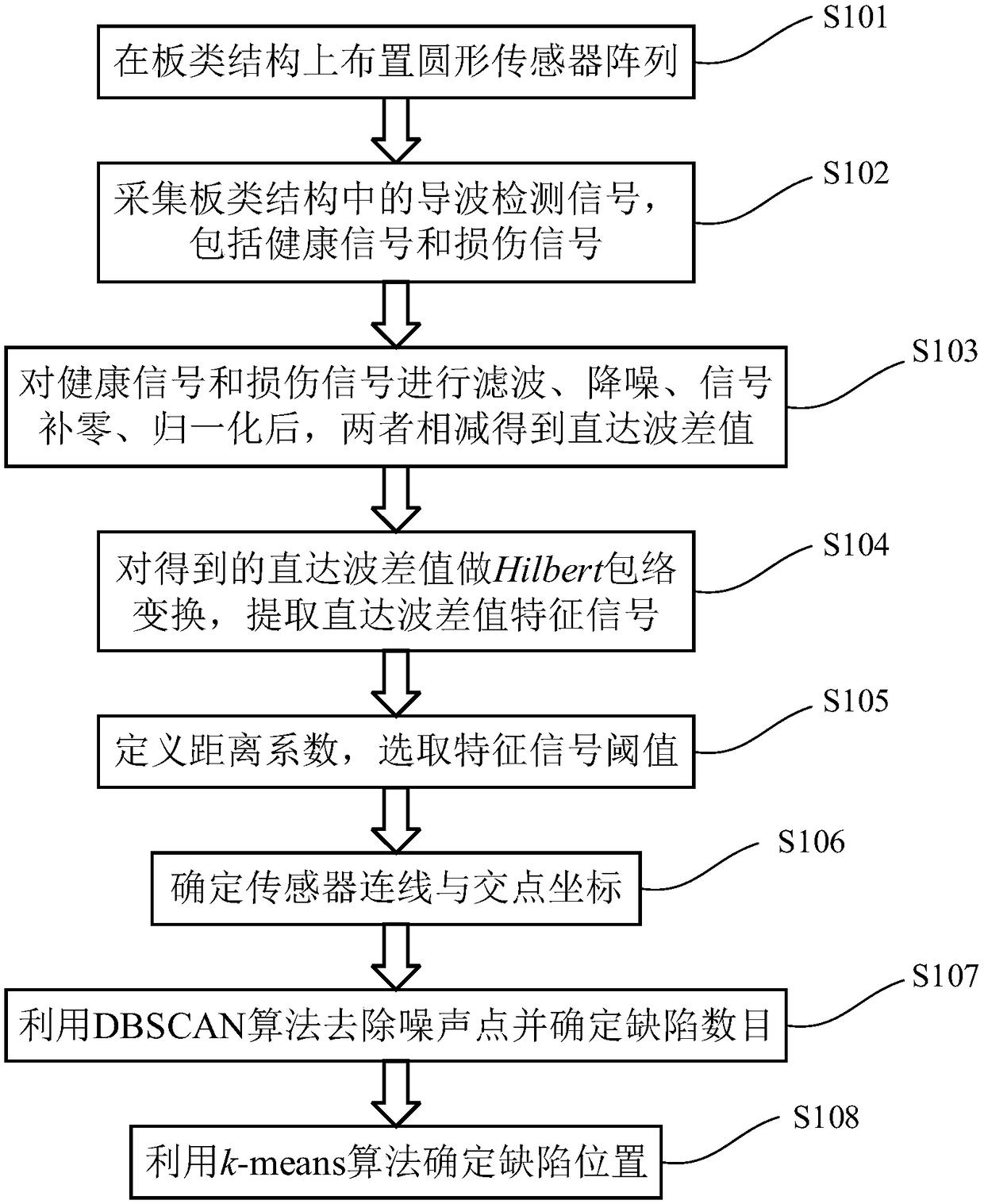

[0050] Such as figure 1 As shown, this example provides a multi-defect detection method for board structures based on DBSCAN and k-means algorithm, including the following steps:

[0051] Step S101: Arranging a sensor array on a board structure.

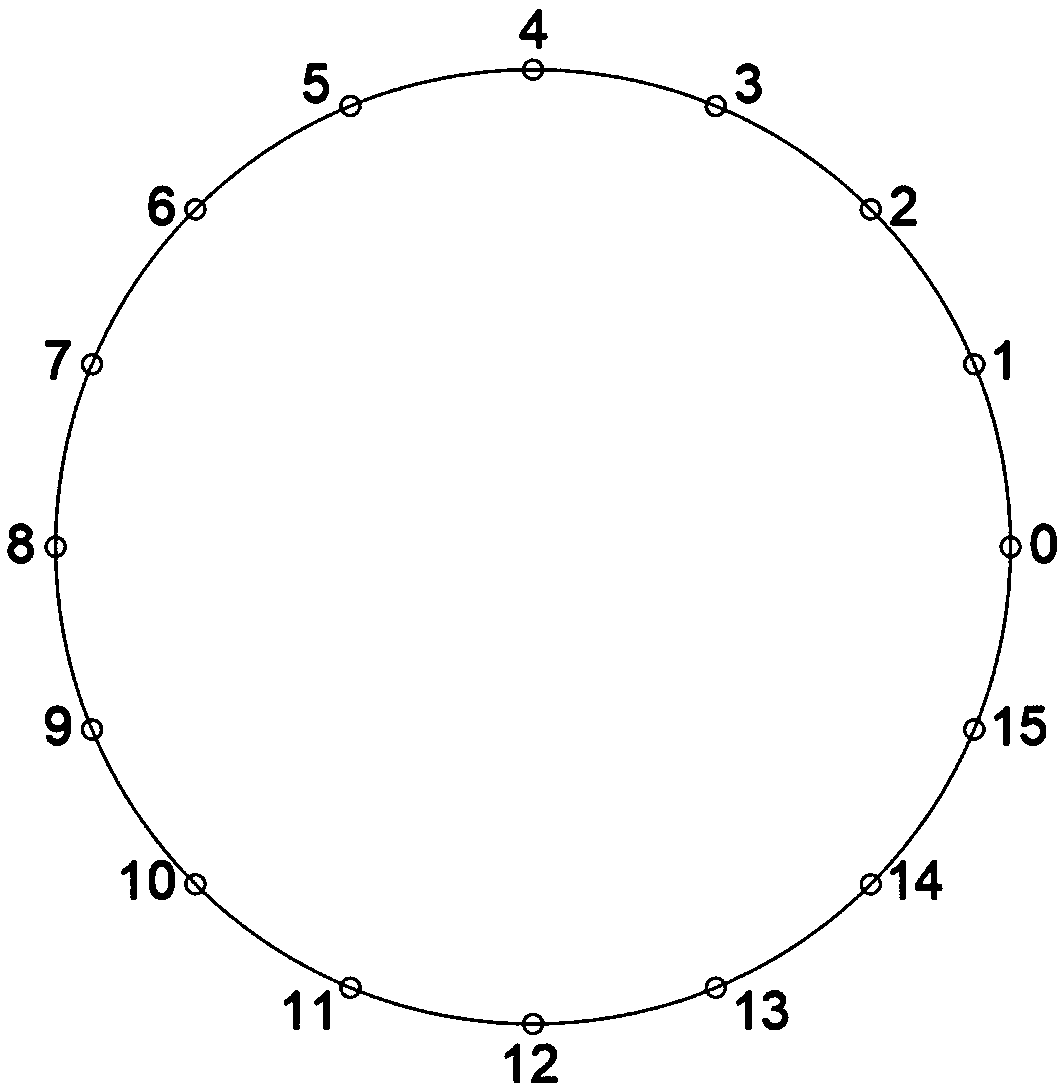

[0052] This embodiment adopts circular sensor array, its structure is as follows figure 2 shown. A sensor array composed of 16 circular piezoelectric wafers is arranged in the center of an aluminum plate of 1000mm×1000mm×3mm, and the array type is a circular sparse array. Among them, the diameter of the piezoelectric chip is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com