Servo motor automatic production equipment for motor rear end cover detection

A technology for servo motors and production equipment, applied in the direction of electric components, manufacturing motor generators, measuring devices, etc., can solve the problems that affect the performance and service life of servo motors, it is difficult to ensure the stability of press-in, and the detection and feedback data are few, etc., to achieve Facilitate automated assembly, increase workpiece capacity, and reduce failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

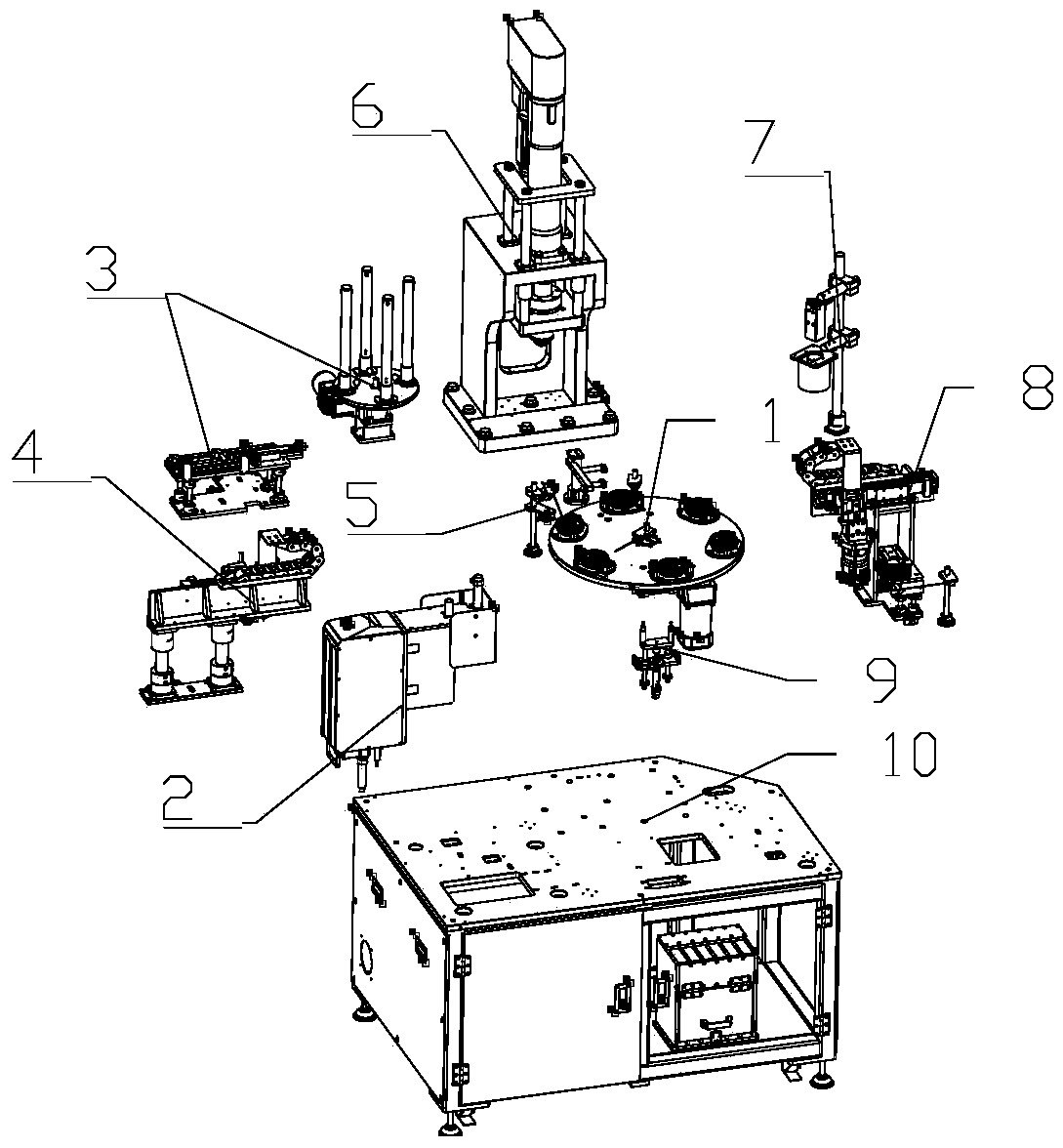

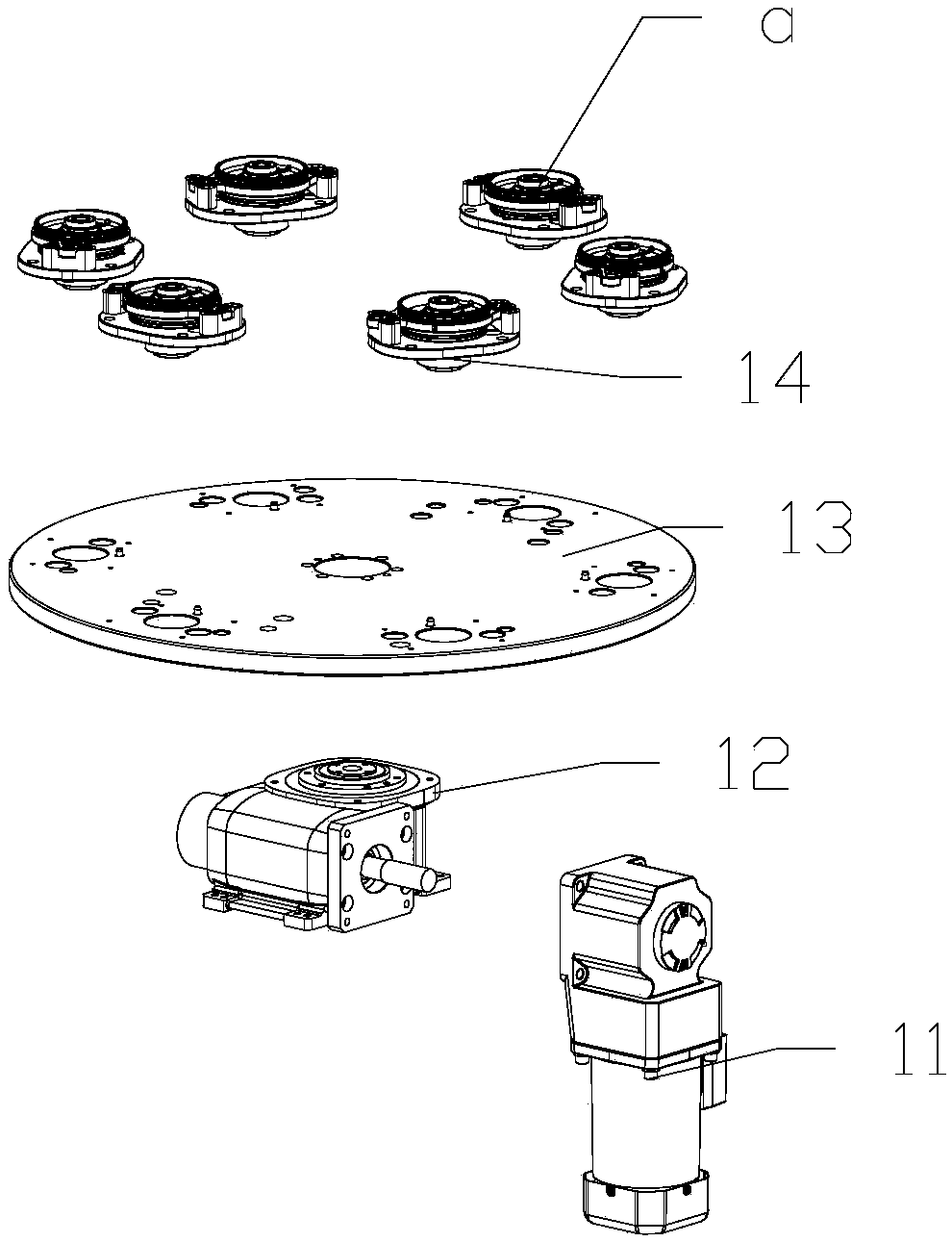

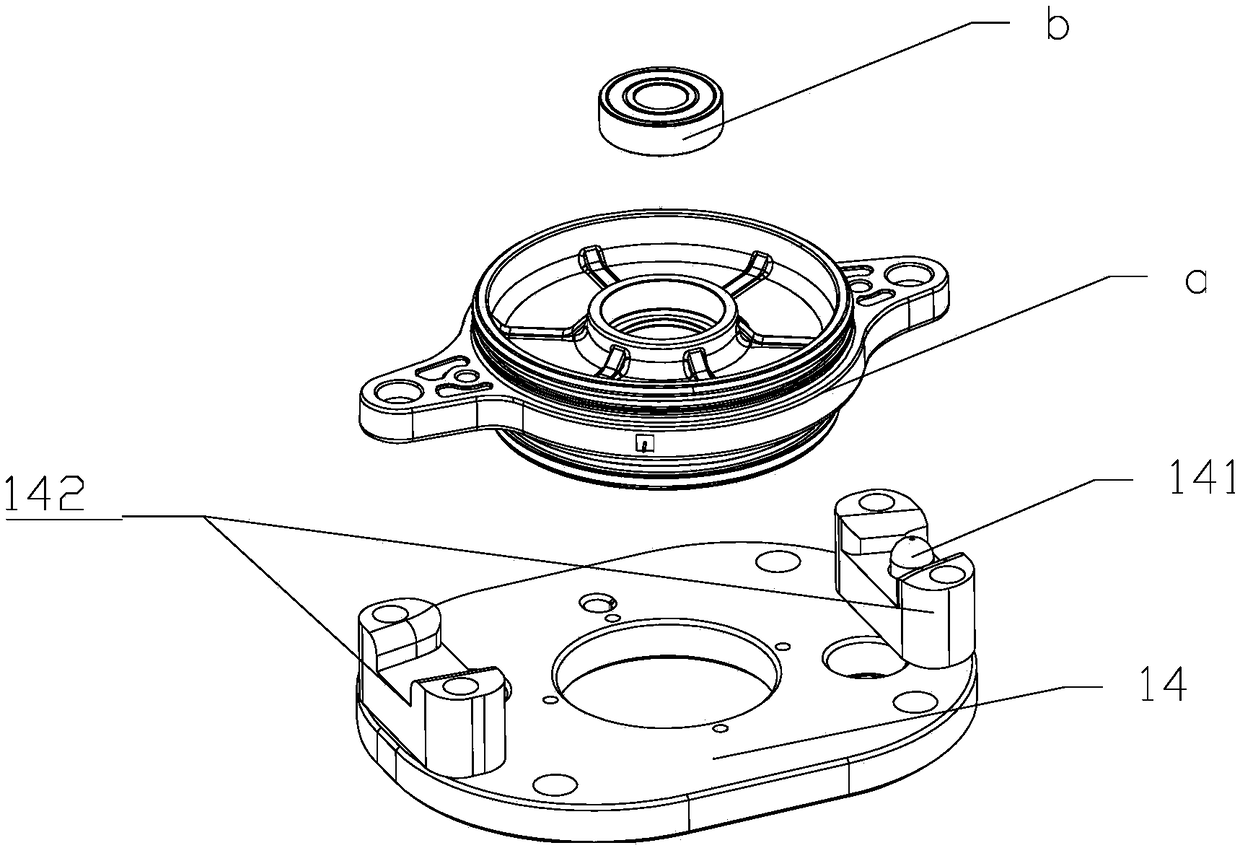

[0037] An automatic assembly system for a servo motor, the system includes a rear end cover bearing press-in equipment, the rear end cover bearing press-in equipment such as figure 1 As shown, it includes indexing turntable device 1, motor rear end cover detection device 2, bearing feeding device 3, bearing handling manipulator device 4, laser information marking device 5, automatic pressing device 6, pressing detection device 7, sealing ring Assembly device 8, finished product ejection device 9 and installation frame 10; installation frame 10 is used to fix and install other devices; indexing turntable device 1 is installed in the middle of installation frame 10, and is used to drive workpieces to circulate among various stations , to complete the corresponding process, the indexing turntable device 1 is sequentially provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com