Video-assisted glue dispensing method for LC optical fiber connector

A fiber optic connector and glue dispensing technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems such as the concentricity and deviation of the tail handle contour circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

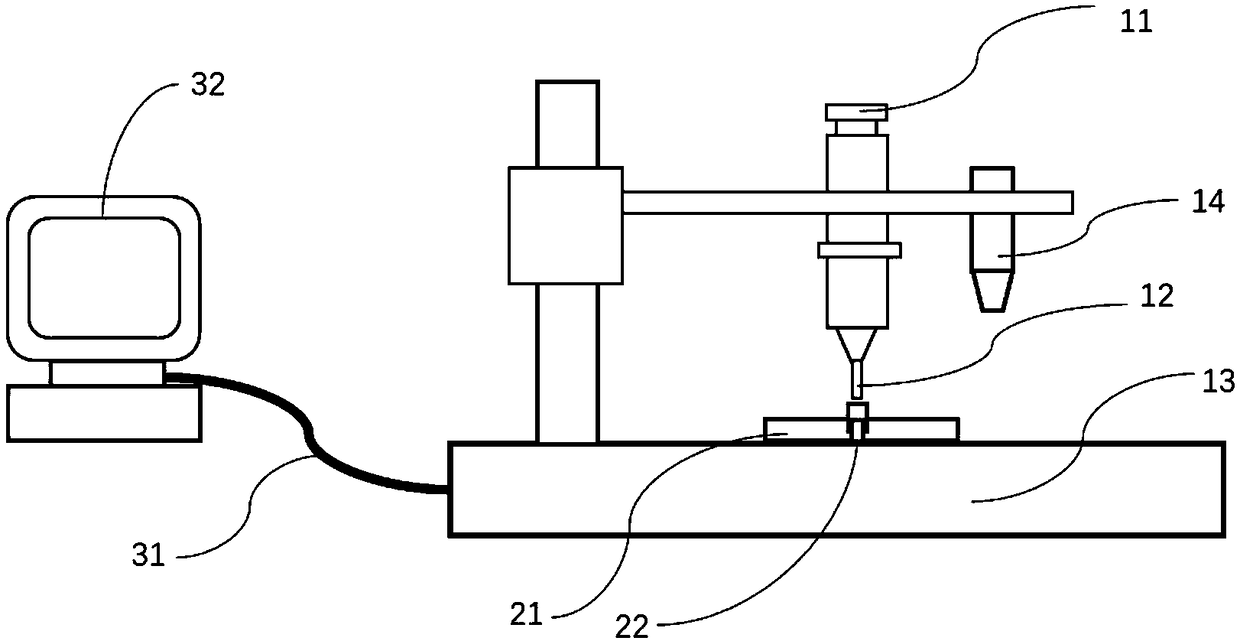

[0046] Such as figure 1 As shown, a dispensing machine is provided, including: a dispensing cylinder 11, a camera 14, a connector fixing fixture 21, a dispensing machine base 13, a control computer 32, and a communication cable 31;

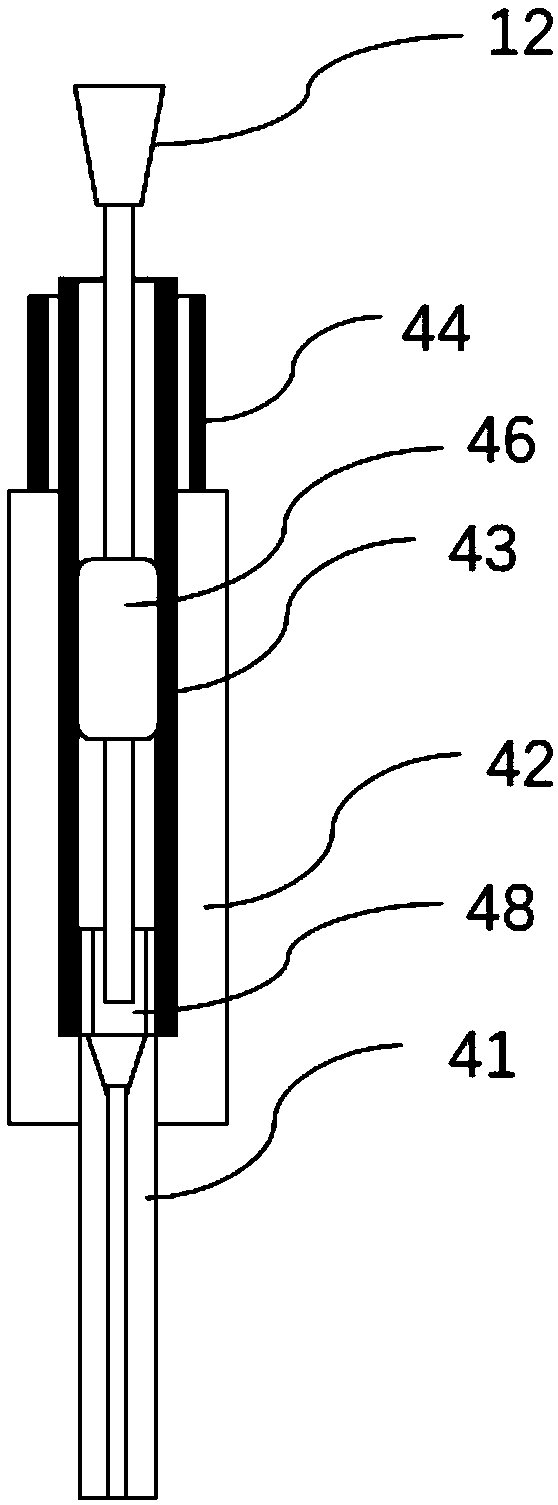

[0047] Further, a flexible dispensing needle 12 is provided, and the flexible needle is installed on the dispensing cylinder 11;

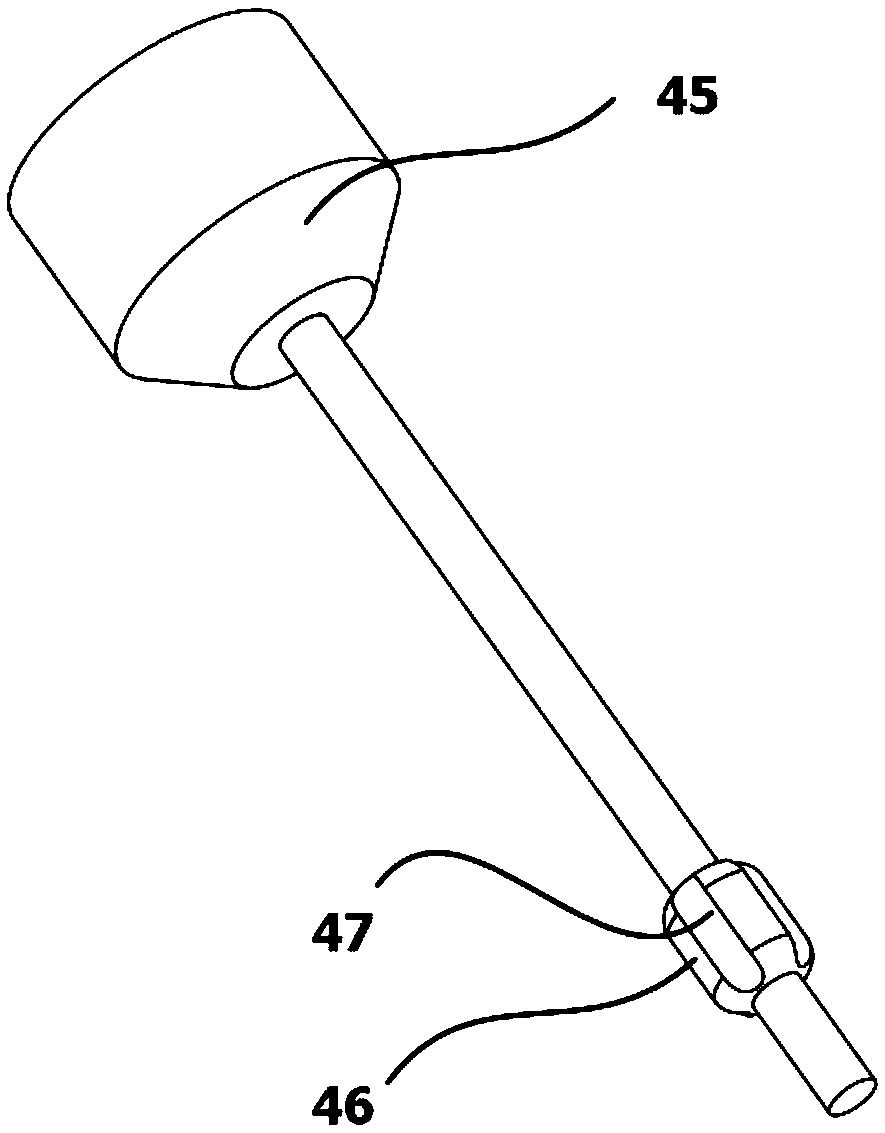

[0048] Further, such as image 3 As shown, a guide 46 is installed on the flexible needle 12;

[0049] Further, an LC type optical fiber connector 22 is provided;

[0050] Further, the LC type optical fiber connector 22 is installed on the dispensing base 13 through the connector fixing fixture 21;

[0051] Further, the tail of the LC-type optical fiber connector is photographed by the camera 14;

[0052] Further, such as Figure 4 As shown, the captured images include: metal support tube tail image 51 and tail sleeve image 53;

[0053] Further, such as Figure 5 As shown, the metal support tube tail image 51 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com