Cooling device for magnetic steel die casting

A technology of cooling device and magnetic steel, applied in the field of die-casting mold equipment, can solve the problems of not well-balanced mold temperature, shortened life, etc., and achieve the effects of easy reuse, improved casting quality, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

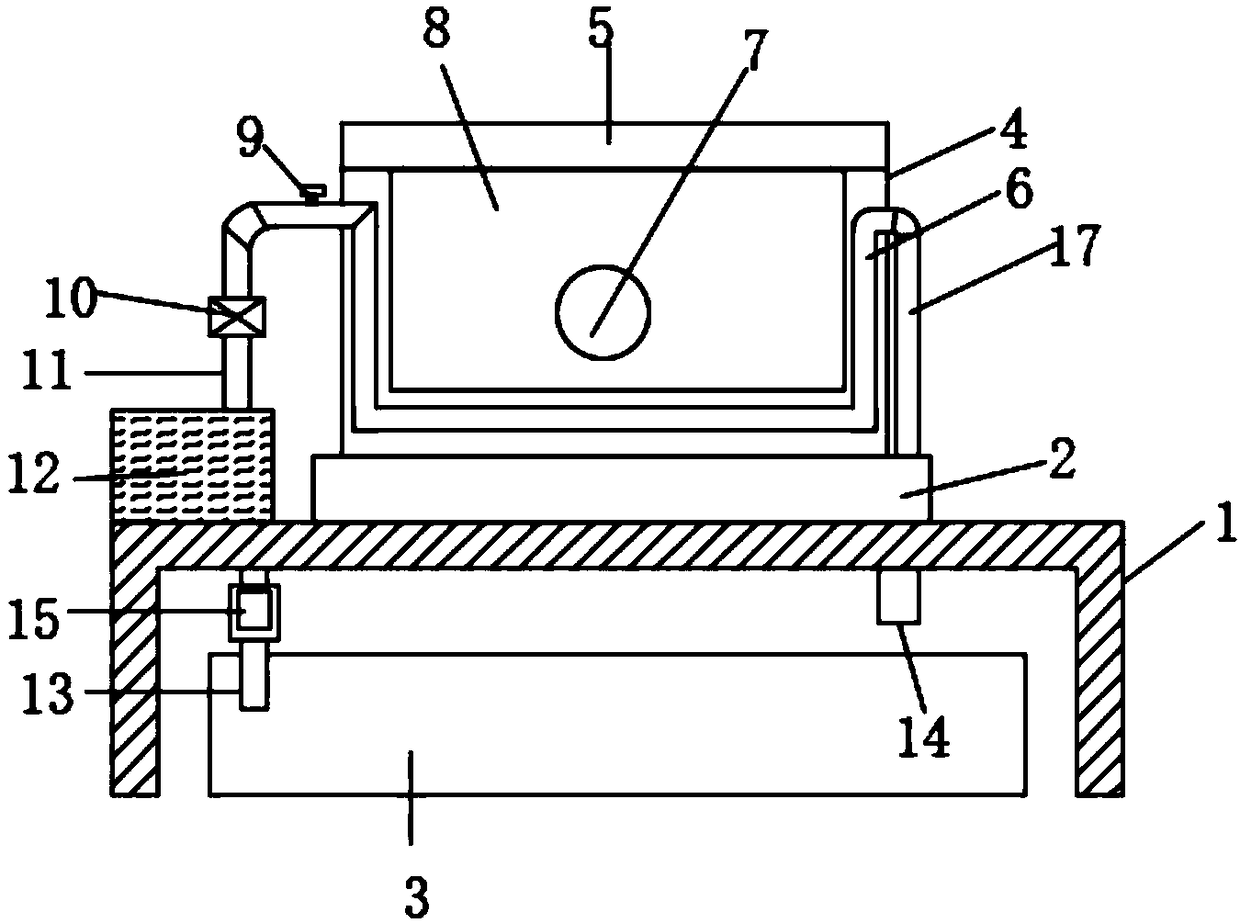

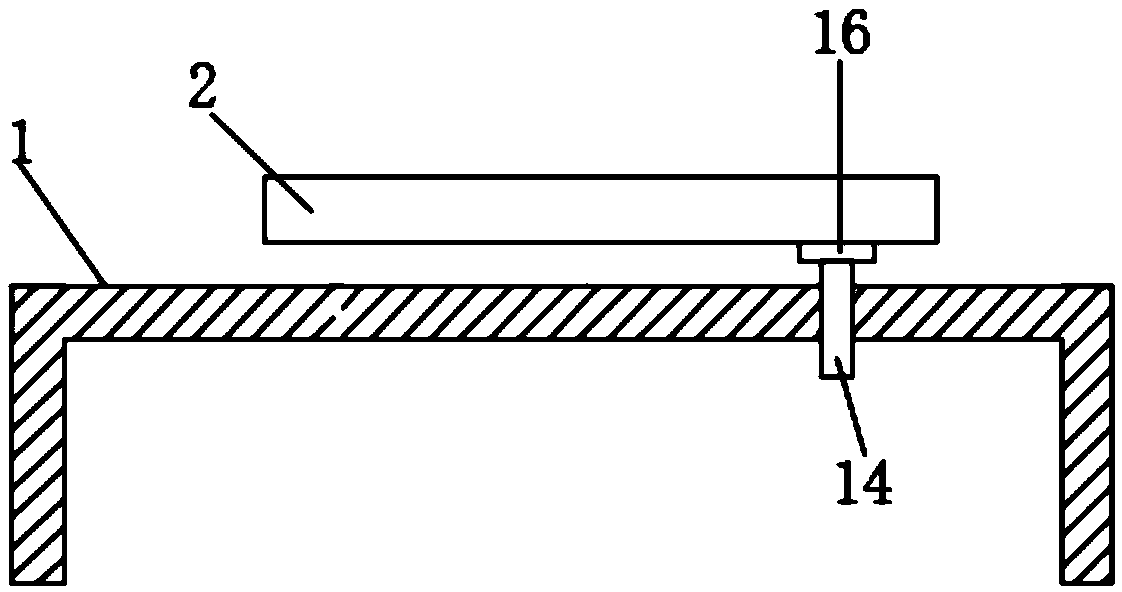

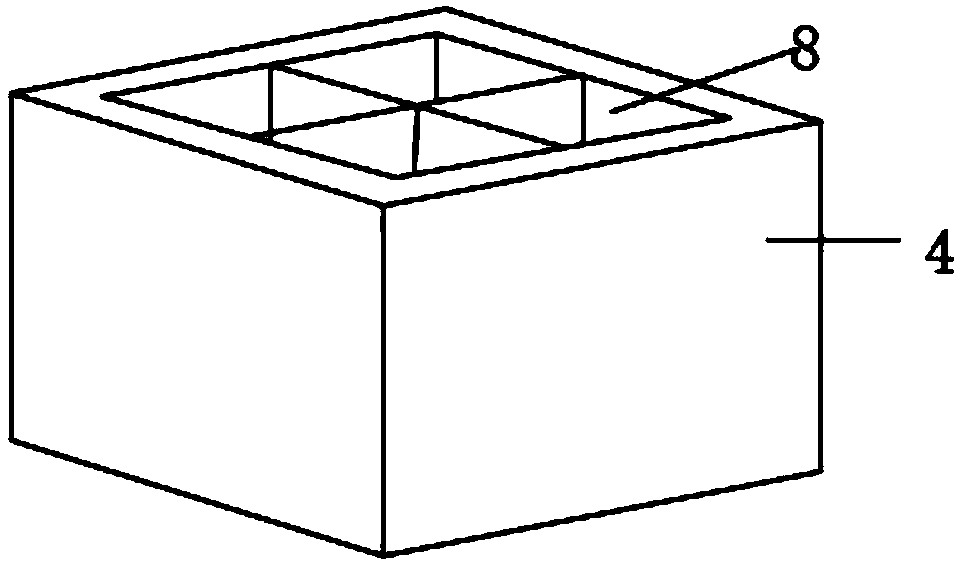

[0019] Such as Figure 1-3 As shown, a cooling device for magnetic steel die-casting includes a support frame 1, and the support frame 1 is fixedly connected with the fixed mold frame 4 through the fixed mold base 2. The front side of the fixed mold frame 4 is provided with a thermometer 7, and the top of the fixed mold frame 4 is provided There is a movable mold base 5, a mold cavity 8 is provided in the middle of the fixed mold base 4 and the movable mold base 5, a water conduit 6 is provided outside the mold cavity 8, a water tank 12 is provided on one side of the support frame 1, and a water inlet pipe is connected inside the water tank 12 11. The water pump 10 is installed on the water inlet pipe 11, and the end of the water inlet pipe 11 away from the water tank 12 extends to the fixed mold frame 4 to connect with the water pipe 6 outside the cavity 8, and the end of the water pipe 6 away from the water inlet pipe 11 is connected to the The pipes 17 are connected, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com