A processing method for high-precision smooth cylindrical graphite samples

A processing method and cylindrical technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as low production efficiency and single process, achieve high grinding efficiency, improve surface grinding quality, and produce stable effect

Active Publication Date: 2019-10-01

SINOSTEEL NEW MATERIAL ZHEJIANG

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

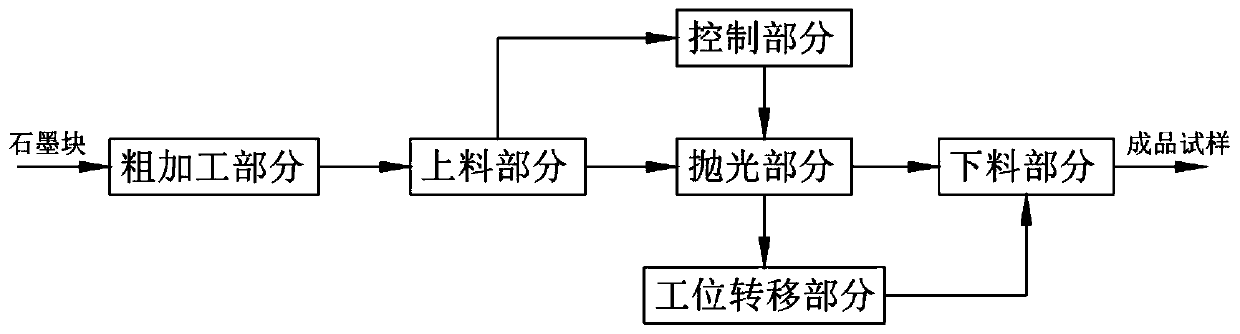

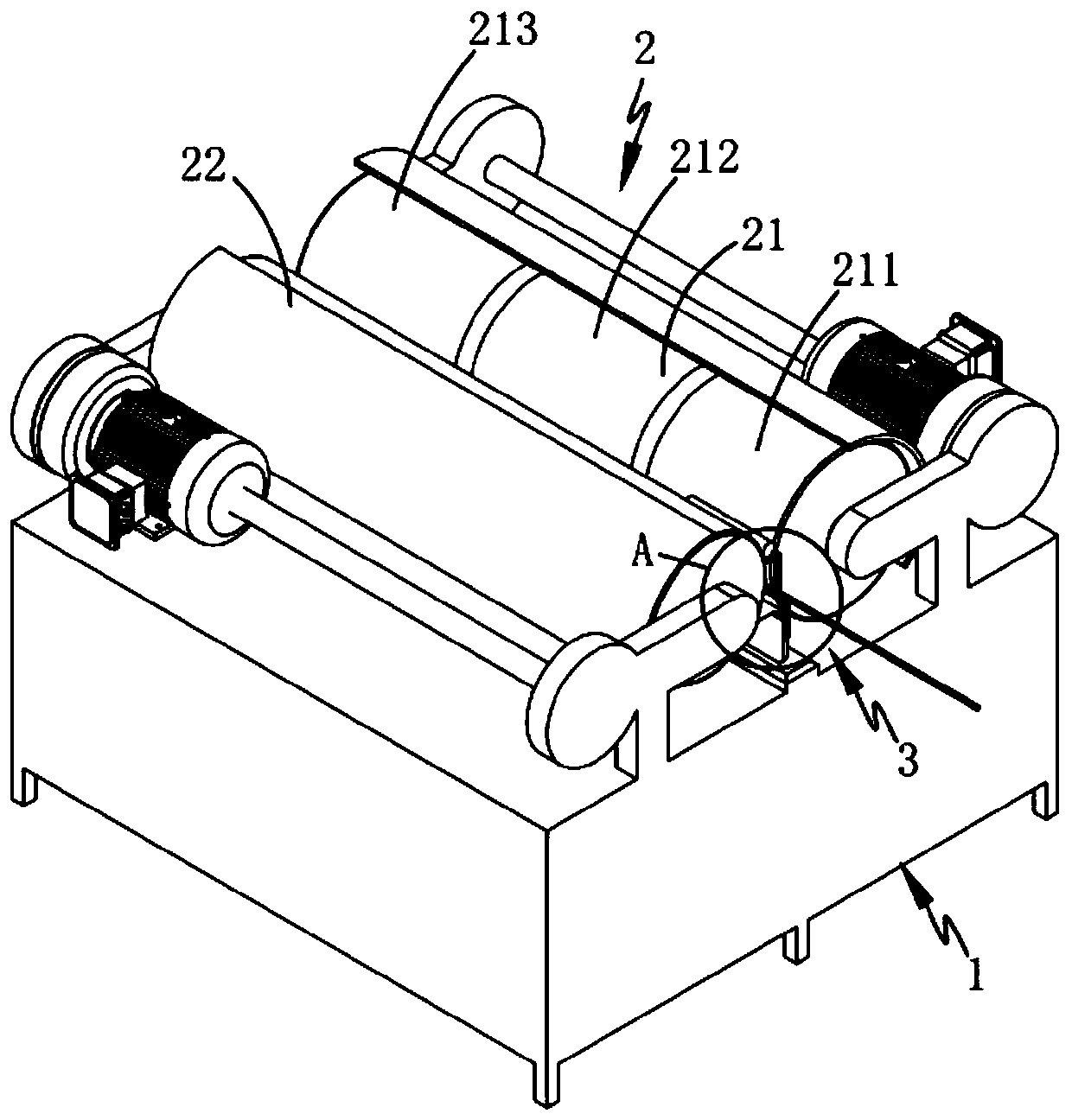

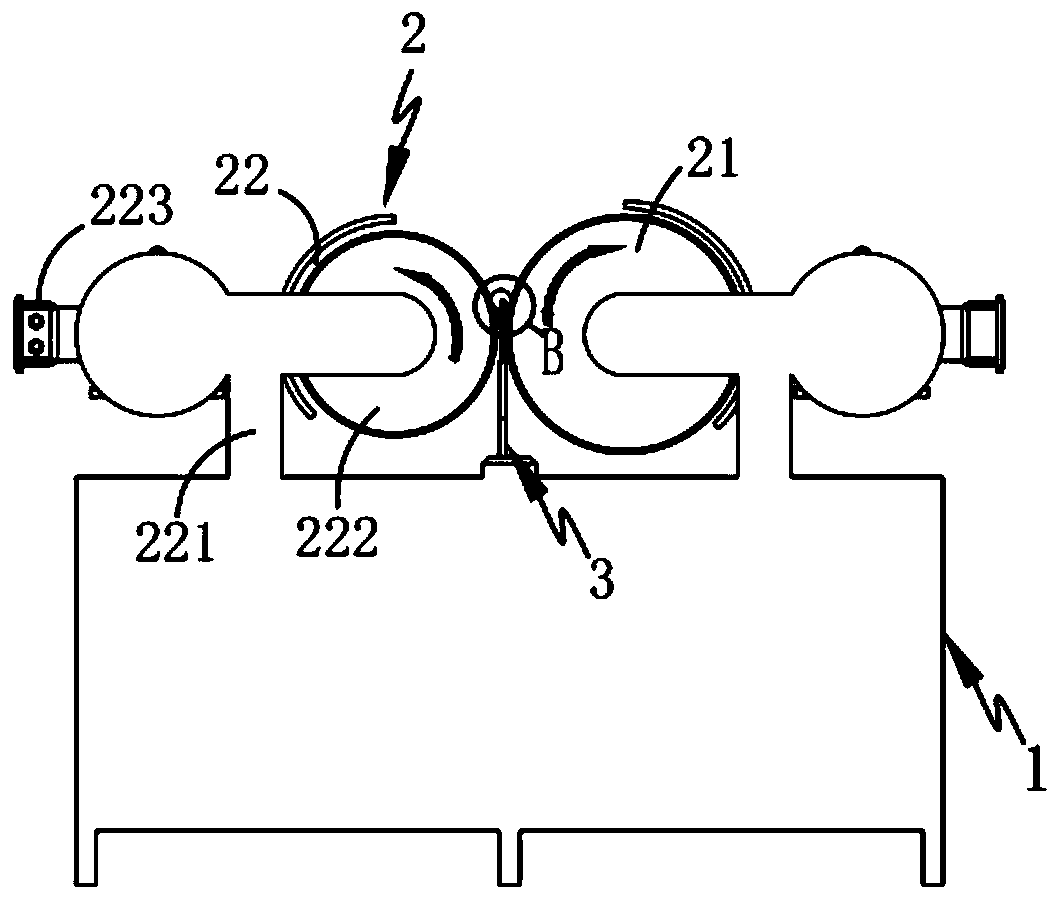

The purpose of the present invention is to address the deficiencies of the prior art and provide a processing method for a high-precision smooth cylindrical graphite sample. The driving assembly drives the directional movement of the sample to rotate in the form of contact friction and at the same time it is connected with the grinding assembly. The multi-stage grinding process is carried out in the same direction of friction, combined with the curved surface guiding method of the guide assembly to the push assembly, so that the sample can automatically perform position conversion during the grinding process, and realize the one-time multi-stage grinding production of cylindrical graphite samples, which solves the problem In the prior art, there are technical problems of single process and low production efficiency in the process of cylindrical graphite processing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of graphite sample processing, in particular to a processing method of a high-accuracy glossy cylindrical graphite sample. The processing method comprises the stepsof roughly processing, feeding, polishing and discharging. The processing method comprises the concrete steps of processing a platy graphite block to obtain the sample with a cylindrical structure, putting the sample on a lifting assembly, transferring the lifting assembly to a polishing station through a pushing assembly, then driving the sample and a grinding assembly through a drive assembly soas to polish in a reverse rubbing manner, and carrying out multistage polishing treatment through a rough grinding part I, a rough grinding part II and an accurate grinding part sequentially; pushingthe lifting assembly through the pushing assembly so as to separate the polished sample from the grinding assembly through a lifting manner, discharging the polished sample through a manual grasp mode; and realizing high-quality processing of the cylindrical graphite through controlling the friction force of the sample and the grinding assembly during a linear multi-station transfer process of the sample and carrying out shape-correction treatment after single-process grinding. The technical problem that the processing efficiency of the cylindrical graphite is low in the prior art is solved.

Description

technical field The invention relates to the field of processing graphite samples, in particular to a method for processing high-precision smooth cylindrical graphite samples. Background technique At present, in the field of artificial graphite production, in order to test various performance indicators of graphite materials, it is necessary to make graphite samples and polish the surface; especially for graphite cylindrical samples with a machining accuracy of 0.005mm and a smoothness Ra≤0.8μm The polishing of cylindrical samples has become the most critical step; the traditional processing method is to process the shape of graphite samples through processing equipment, and then grind them through cylindrical grinding; due to the loose texture of graphite, its processing is difficult Larger, especially for higher surface accuracy requirements, and its processing efficiency is low. Chinese patent application number is: 2015206272442 disclosed carbon graphite rod hole proce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B27/00B24B37/02B24B37/34

Inventor 杨辉许汉春吴厚政

Owner SINOSTEEL NEW MATERIAL ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com