A kind of manufacturing process and equipment of colored ultra-thin mica sheet

A production process and technology of mica sheets, which are applied in the field of building decoration materials, can solve the problems of environmental pollution, high building load and high cost, and achieve the effects of avoiding dust pollution of the environment, reducing labor intensity and solving high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

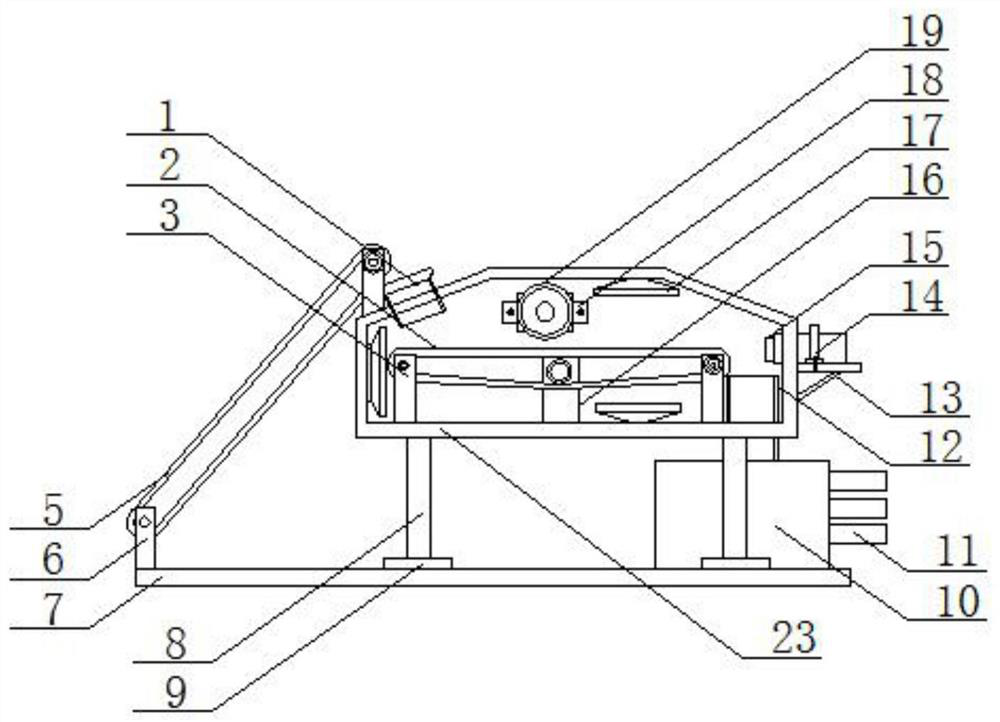

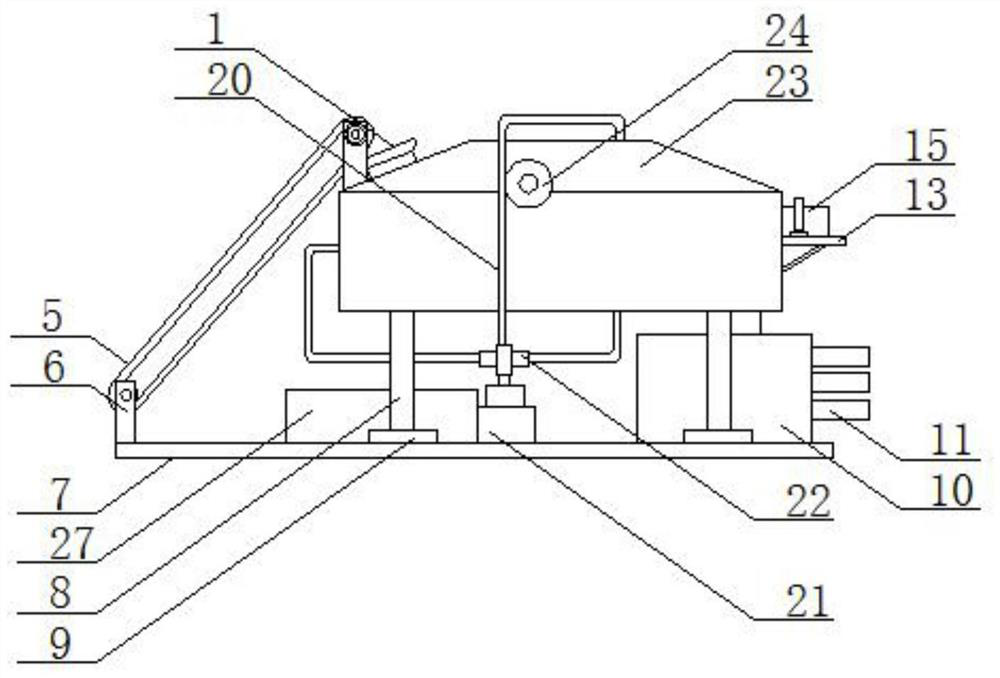

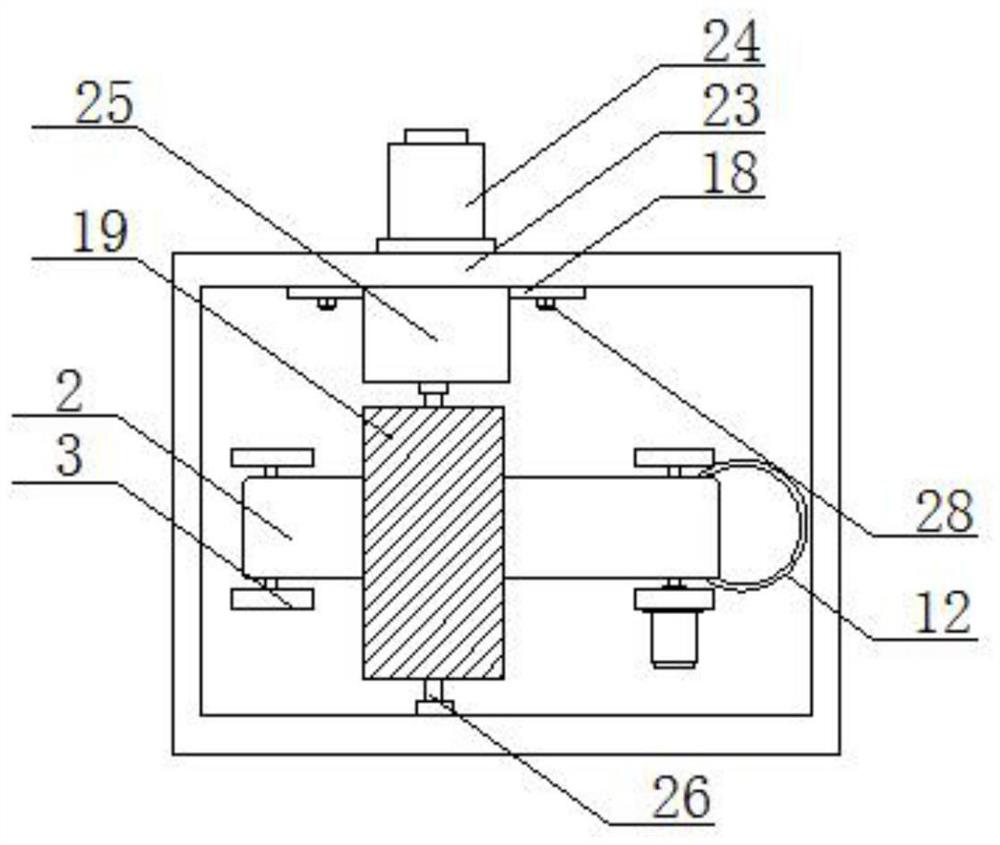

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0039] refer to Figure 1-4, a kind of production equipment of colored ultra-thin mica sheet, comprises base plate 7, is convenient to support and fix, and the upper end of base plate 7 is fixed with four backing plates 9, and the upper end of backing plate 9 is fixed with support bar 8, plays the role of support, The upper ends of four support rods 8 are jointly fixed with fixed box 23, and the bottom in the fixed box 23 is provided with the first conveying device, conveniently drives mica sheet to polish, is provided with polishing device in the fixed box 23, and the polishing device and the first conveying device Corresponding to each other, the lower end side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com