A method and application of recovering and preparing titanium-tungsten powder from waste scr denitrification catalyst

A denitrification catalyst and waste catalyst technology, applied in the direction of improving process efficiency, etc., can solve the problems of high cost and complicated recycling process, and achieve the effect of easy operation, simple process, and closed-circuit recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

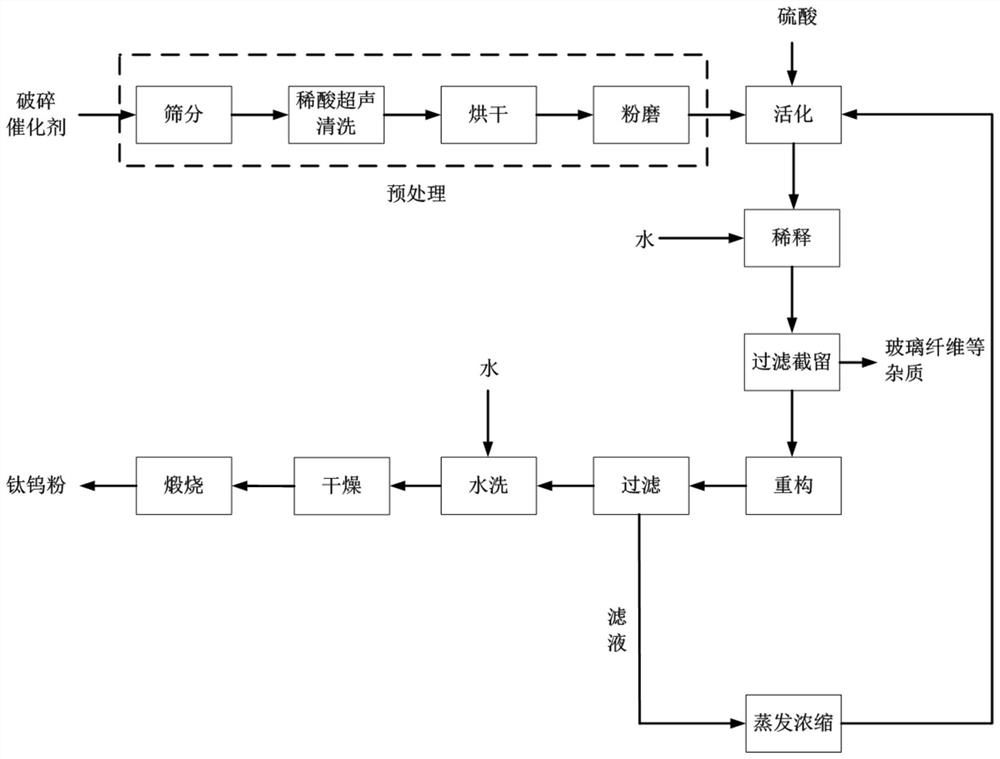

[0054] This embodiment provides a method for recovering and preparing titanium-tungsten powder from a waste SCR denitration catalyst, the process flow of the method is as follows figure 1 As shown, the method includes the following steps:

[0055] (1) After the waste SCR denitration catalyst is screened, it is added to dilute sulfuric acid with a mass fraction of 0.5 wt%, soaked under ultrasonic conditions, dried and ground to obtain a pretreated spent catalyst powder, the pretreated spent catalyst powder The particle size of the body is 100 mesh;

[0056] (2) Use sulfuric acid with a concentration of 70wt%, 170°C and mechanical stirring to activate the spent catalyst powder obtained in step (1) for 180min. After the reaction, cool down to 120°C and dilute with water under stirring to obtain rough activation slurry, the mass ratio of pure sulfuric acid contained in the sulfuric acid to the pretreated spent catalyst powder is 4:1, and the mass ratio of the dilution water to th...

Embodiment 2

[0065] This embodiment provides a method for recovering and preparing titanium-tungsten powder from a waste SCR denitration catalyst, the method comprising the following steps:

[0066] (1) After the waste SCR denitrification catalyst is screened, it is added to dilute sulfuric acid with a mass fraction of 5wt%, soaked under ultrasonic conditions, dried and ground to obtain a pretreated spent catalyst powder, the pretreated spent catalyst powder The particle size is 200 mesh;

[0067] (2) Use sulfuric acid with a concentration of 80wt%, 150°C and mechanical stirring to activate the pretreated spent catalyst powder obtained in step (1) for 10 minutes. After the reaction, cool down to 90°C and dilute with water under stirring to obtain rough activated slurry, the mass ratio of the pure sulfuric acid contained in the sulfuric acid to the pretreated spent catalyst powder is 3:1, and the mass ratio of the dilution water to the pretreated spent catalyst powder is 10:1 ;

[0068] (...

Embodiment 3

[0076] This embodiment provides a method for recovering and preparing titanium-tungsten powder from a waste SCR denitration catalyst, the method comprising the following steps:

[0077] (1) After the waste SCR denitrification catalyst is screened, it is added to dilute sulfuric acid with a mass fraction of 10wt%, soaked under ultrasonic conditions, dried and ground to obtain a pretreated spent catalyst powder, the pretreated spent catalyst powder The particle size is 300 mesh;

[0078] (2) Use sulfuric acid with a concentration of 85wt%, 140°C and mechanical stirring to activate the spent catalyst powder obtained in step (1) for 30 minutes. After the reaction, cool down to 100°C and dilute with water under stirring to obtain rough activated slurry, the mass ratio of pure sulfuric acid contained in the sulfuric acid to the pretreated spent catalyst powder is 2:1, and the mass ratio of the dilution water to the pretreated spent catalyst powder is 8:1 ;

[0079] (3) 400 purpose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com