Aluminum alloy material capable of being used for online hydrogen supply

A technology of aluminum alloy materials and alloys, which is applied in the field of aluminum alloy materials, can solve the problems of difficult and stable application, unstable hydrogen production rate of alloys, etc., and achieve the effect of promoting hydrolysis reaction, stable hydrogen production rate, and satisfying online hydrogen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

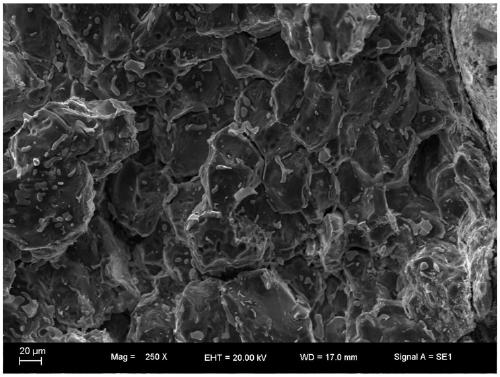

[0024] With 90wt% Al bulk, 3.2wt% Ga, 5wt% In and Sn, where the atomic ratio of In:Sn is 3:1, 1.8wt% Al with a size of 200 mesh 2 o 3 Granules are used as raw materials, melted at 800°C for 1.5h in a stirred furnace filled with nitrogen protection gas, then stirred at 60r / min for 15 minutes, poured into steel molds, and obtained Al-Ga-In-Sn-Al after natural cooling 2 o 3 alloy. Its SEM characterization picture is as follows figure 1 shown.

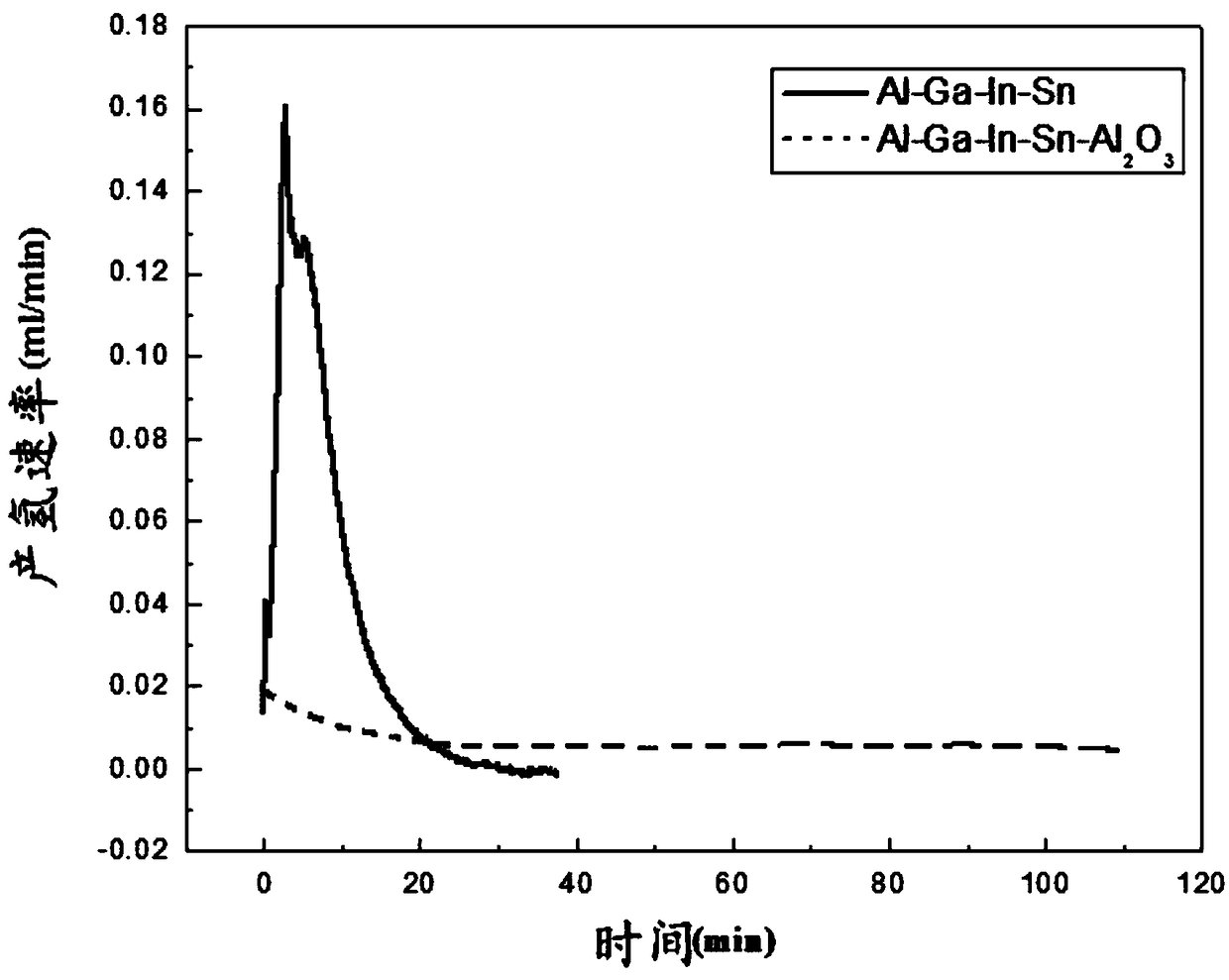

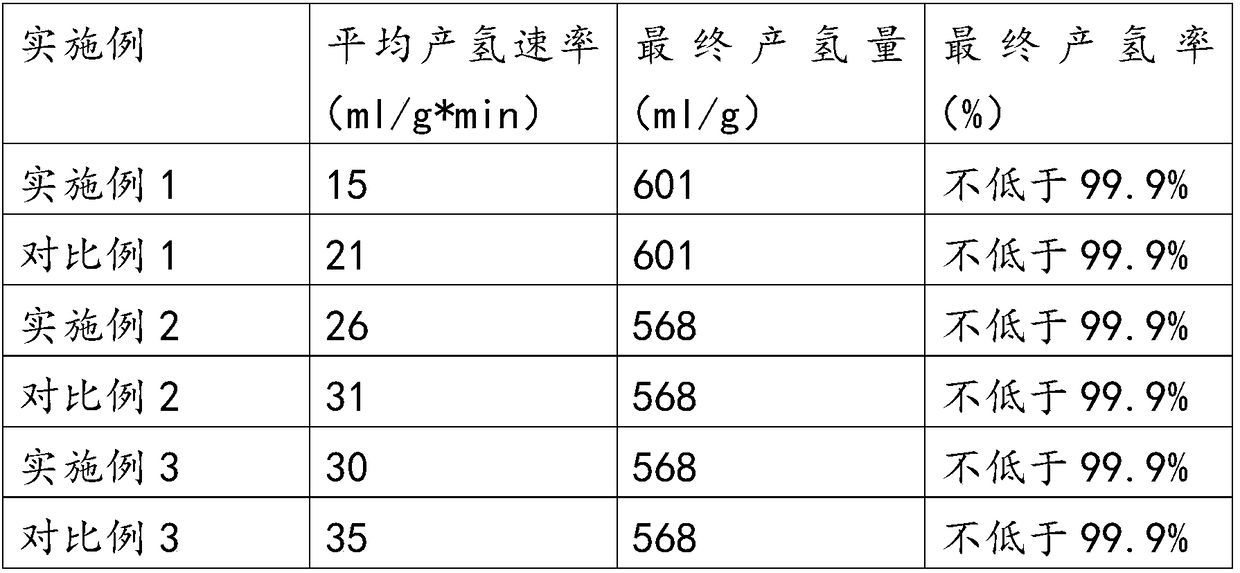

[0025] Take 1 g of the prepared aluminum alloy and carry out hydrolysis reaction with distilled water at 40 degrees at room temperature of 20 degrees. The hydrogen production performance of hydrolysis is shown in Table 1, and the instantaneous hydrogen production rate is as figure 2 shown.

Embodiment 2

[0029] With 85wt% Al bulk, 3.5wt% Ga, 9wt% In and Sn, where the atomic ratio of In:Sn is 3:1, 2.5wt% Al with a size of 100 mesh 2 o 3 Granules are used as raw materials, melted at 900°C for 1 hour in a stirred furnace filled with nitrogen protection gas, stirred at 80r / min for 12 minutes, poured into steel molds, and obtained Al-Ga-In-Sn-Al after natural cooling 2 o 3 alloy.

[0030] Take 1 g of the prepared aluminum alloy and carry out hydrolysis reaction with distilled water at 40°C, and the measured hydrogen production performance by hydrolysis is shown in Table 1.

Embodiment 3

[0034] With 85wt% Al bulk, 5wt% Ga, 8wt% In and Sn, where the atomic ratio of In:Sn is 3:1, 2wt% Al with a size of 100 mesh 2 o 3Granules are used as raw materials, melted at 800°C for 1 hour in a stirred furnace filled with nitrogen protection gas, stirred at 70r / min for 20 minutes, poured into steel molds, and obtained Al-Ga-In-Sn-Al after natural cooling 2 o 3 Alloy materials.

[0035] Take 1 g of the prepared aluminum alloy and carry out hydrolysis reaction with distilled water at 40°C, and the measured hydrogen production performance by hydrolysis is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com