High strength and high extending nodular iron casting and preparation method thereof

A nodular cast iron, high-strength technology, applied in the field of nodular graphite cast iron, can solve problems such as deficiencies and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

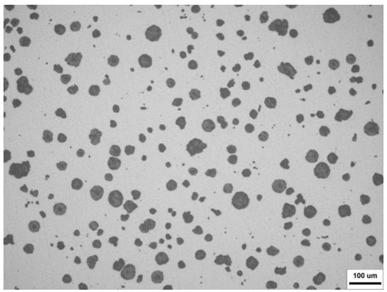

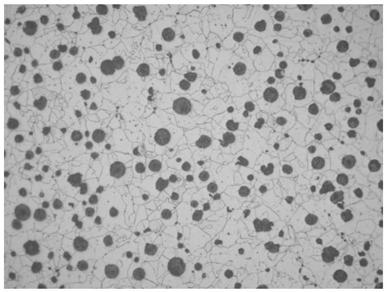

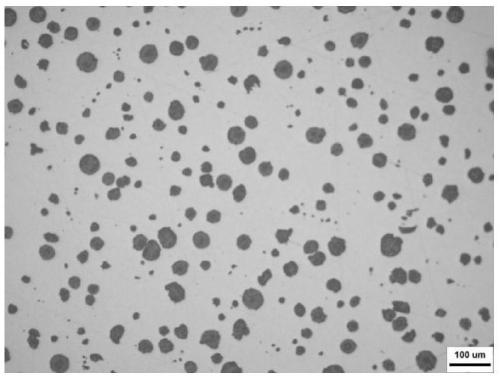

Image

Examples

Embodiment 1

[0042] This embodiment provides a high-strength and high-elongation ductile iron casting. The ductile iron casting includes the following components: in terms of mass percentage, the mass fraction of each component in the ductile iron casting is: C: 3.1% , Si: 4.1%, Mn: 0.15%, P: 0.04%, S: 0.015%, Cu: 0.04%, Sn: 0.008%, Mg: 0.04%, Cr: 0.03%, Ti: 0.02%, Ni: 0.015% , Al:0.03%, Mo:0.02%, Co:0.008%, V:0.015%, Sb:0.002%, Ce:0.003%, As:0.006%, Pb:0.0015%, Bi:0.001%, Te:0.002% And B: 0.001%, the rest is Fe and unavoidable impurities.

[0043] Its preparation method is as follows: described preparation method comprises:

[0044] (1) Weigh each component according to the formula ratio, then mix and melt at 1500-1550°C to obtain a melt;

[0045] (2) The contents of each component in the molten liquid prepared in the detection step (1) are compared with the ratio of the formula, if consistent, then proceed to the next step, if not, adjust by adding materials to make the detection The ...

Embodiment 2

[0051] This embodiment provides a high-strength and high-elongation ductile iron casting. The ductile iron casting includes the following components: in terms of mass percentage, the mass fraction of each component in the ductile iron casting is: C: 3.2% , Si: 4.2%, Mn: 0.15%, P: 0.04%, S: 0.015%, Cu: 0.04%, Sn: 0.008%, Mg: 0.04%, Cr: 0.03%, Ti: 0.02%, Ni: 0.015% , Al:0.03%, Mo:0.02%, Co:0.008%, V:0.015%, Sb:0.002%, Ce:0.003%, As:0.006%, Pb:0.0015%, Bi:0.001%, Te:0.002% And B: 0.001%, the rest is Fe and unavoidable impurities.

[0052] Its preparation method is as follows: described preparation method comprises:

[0053] (1) Weigh each component according to the formula ratio, then mix and melt at 1500-1550°C to obtain a melt;

[0054] (2) The contents of each component in the molten liquid prepared in the detection step (1) are compared with the ratio of the formula, if consistent, then proceed to the next step, if not, adjust by adding materials to make the detection The ...

Embodiment 3

[0060] This embodiment provides a high-strength and high-elongation ductile iron casting. The ductile iron casting includes the following components: in terms of mass percentage, the mass fraction of each component in the ductile iron casting is: C: 3.3% , Si: 4.3%, Mn: 0.15%, P: 0.04%, S: 0.015%, Cu: 0.04%, Sn: 0.008%, Mg: 0.04%, Cr: 0.03%, Ti: 0.02%, Ni: 0.015% , Al:0.03%, Mo:0.02%, Co:0.008%, V:0.015%, Sb:0.002%, Ce:0.003%, As:0.006%, Pb:0.0015%, Bi:0.001%, Te:0.002% And B: 0.001%, the rest is Fe and unavoidable impurities.

[0061] Its preparation method is as follows: described preparation method comprises:

[0062] (1) Weigh each component according to the formula ratio, then mix and melt at 1500-1550°C to obtain a melt;

[0063] (2) The contents of each component in the molten liquid prepared in the detection step (1) are compared with the ratio of the formula, if consistent, then proceed to the next step, if not, adjust by adding materials to make the detection The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com