Battery cell testing device and method for thermal battery

A single battery and testing device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of long preparation time of thermal batteries, large demand for powder materials, difficult serialization research, etc., to speed up research and development Single battery process, low contact internal resistance, and the effect of alleviating contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Single battery preparation

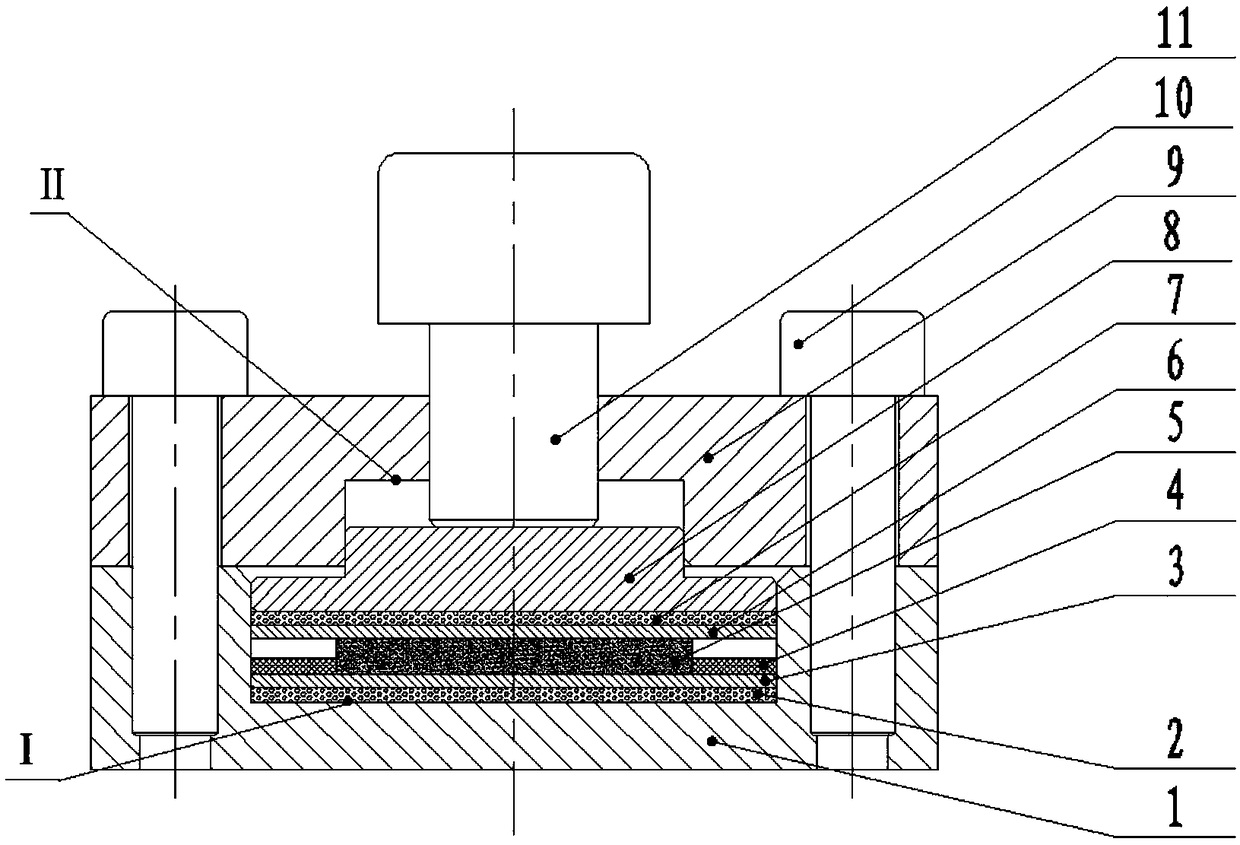

[0033] The single battery 5 includes a graphite substrate, negative electrode material, diaphragm material, and positive electrode material.

[0034] 1) negative electrode material: the negative electrode material is LiB alloy;

[0035] 2) Preparation of diaphragm material: Take ternary all-lithium electrolyte LiF-LiCl-LiBr and MgO, according to mass ratio, ternary all-lithium electrolyte LiF-LiCl-LiBr:MgO=1:1, mix well. The ternary all-lithium electrolyte LiF-LiCl-LiBr is composed of 9.6% anhydrous LiF, 22% anhydrous LiCl and 68.4% LiBr by weight percentage.

[0036] 3) Preparation of cathode material:

[0037] a) Vacuum drying: take NiS respectively 2 , FeS 2 , Li 2 O and the binary electrolyte LiCl-KCl are placed in a vacuum drying oven for drying, the drying temperature is 120±10°C, the relative vacuum degree is ≤-0.09Mpa, and the drying time is 8 hours. The binary electrolyte LiCl-KCl is composed of 45 wt% anhydrous LiCl and 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap