Quantification method for lithium deposition in lithium ion battery anode

A lithium-ion battery and quantification method technology, which is applied in the quantification field of lithium-ion battery negative electrode analysis, can solve the problems of reducing battery safety, fire, affecting battery capacity, etc., and achieves simple and easy test methods, accurate and reliable test results, The effect of good practicality and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, a soft-pack battery cell with a capacity of 8Ah is used, and the system is an NCM / C system. The system stipulates a lower limit voltage of 2.8V and a stipulated upper limit voltage of 4.2V.

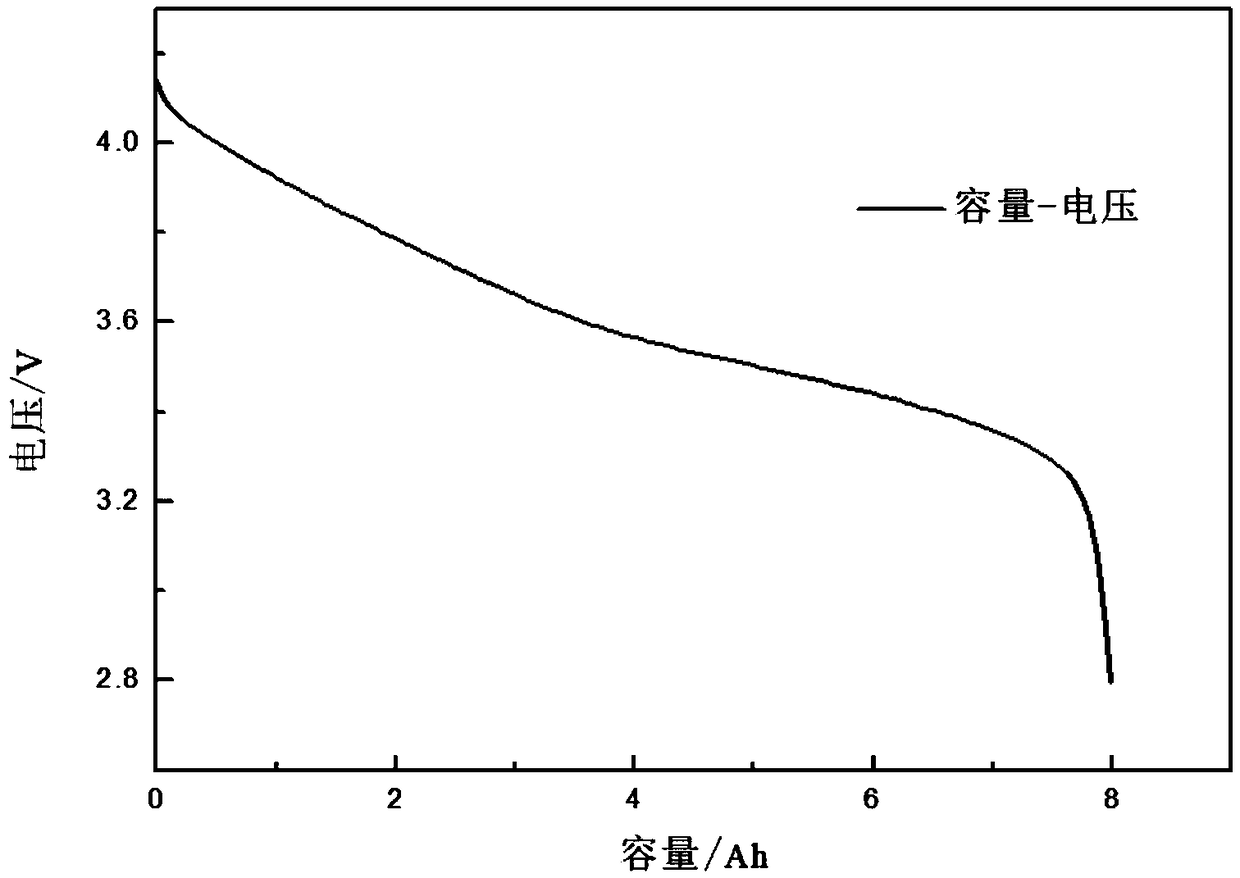

[0037] a. Put the 8Ah soft-packed battery cell at 25℃ for 10h, discharge it to 2.8V with 1C current, and let it stand for 1h; charge it with 1C constant current to 4.2V, then transfer to constant voltage charging until the current ≤0.05C to stop, Let stand for 1h, then discharge to 2.8V at 1C, stand for 1h, cycle the above charging and discharging process for 3 weeks, the discharge curve of the last week is as follows figure 1 As shown, the discharge capacity of 8.02 Ah in the last week is recorded as Ca. ;

[0038] b. Put the battery cell in a 0℃ low temperature environment and let it stand for 10 hours;

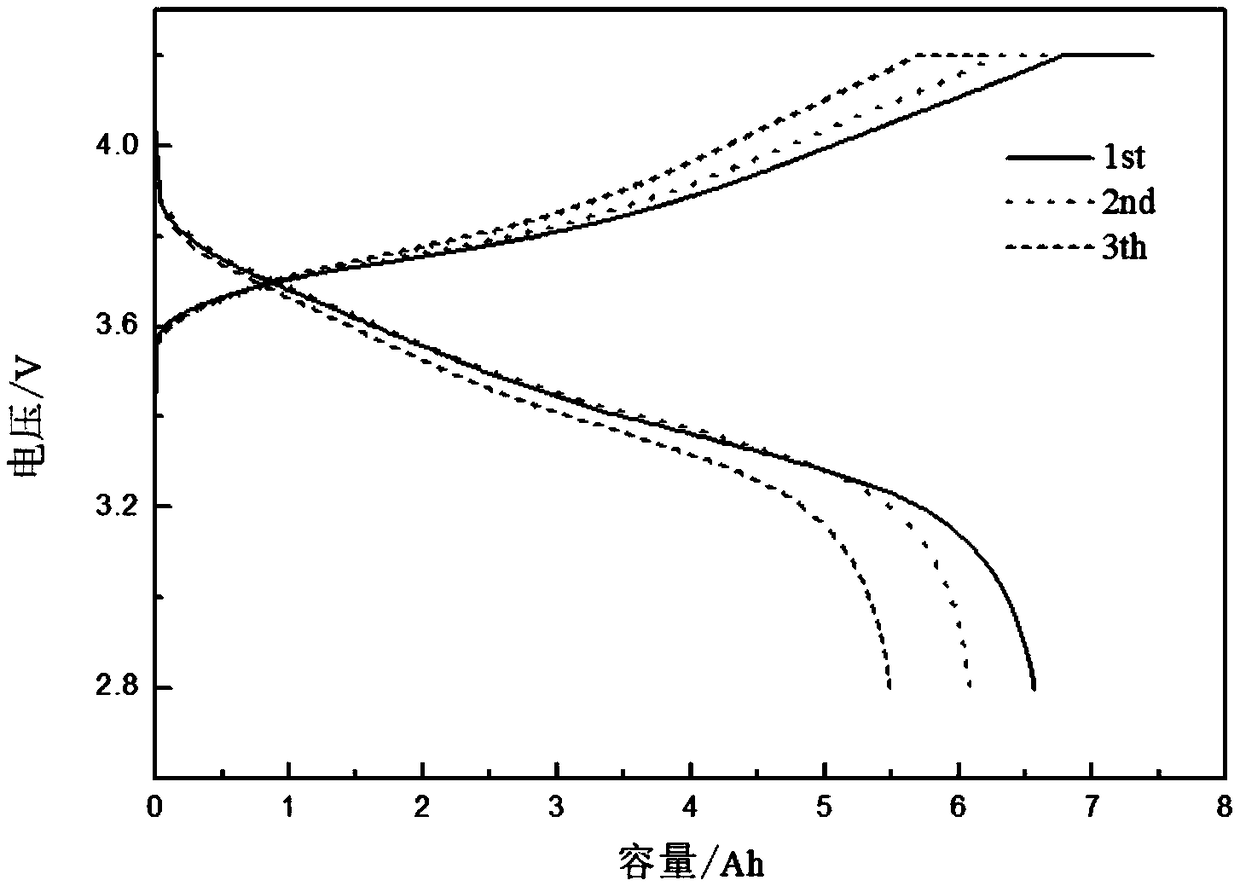

[0039] c. Charge the battery in step b with a 1C high-rate current to 4.2V at the 0°C, then switch to constant-voltage charging until the current is ≤0.05C, stop, ...

Embodiment 2

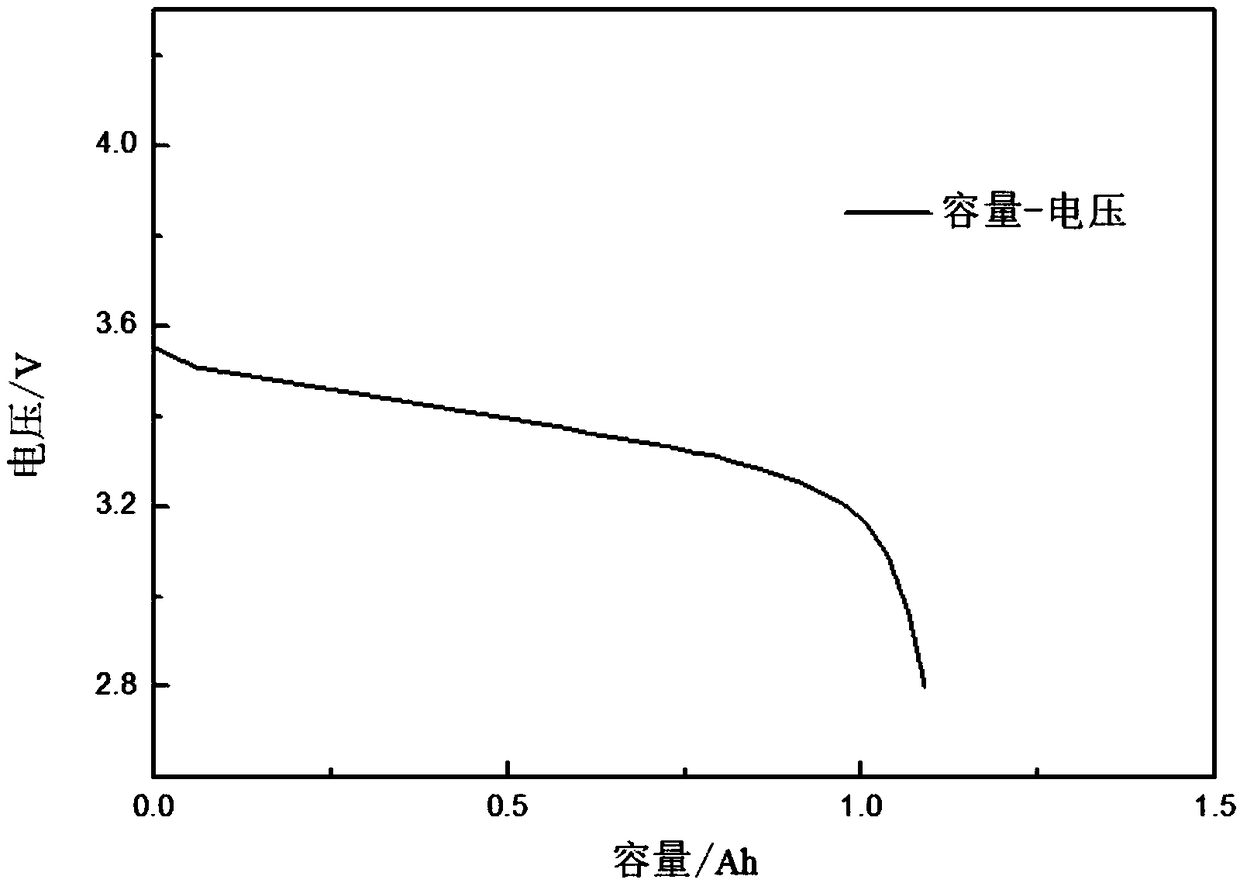

[0045] The low temperature environment was changed to -10°C, and the remaining experimental conditions were the same as in Example 1. Ca was obtained as 8.08Ah, Cb was 0.78Ah, and the amount of lithium deposited in the negative electrode at -10°C was calculated. The results are shown in Table 1.

Embodiment 3

[0047] The low temperature environment was changed to -20°C, and the other experimental conditions were the same as in Example 1. Ca was obtained as 8.05Ah and Cb was 1.08Ah. The amount of lithium deposited in the negative electrode at -20°C was calculated. The results are shown in Table 1.

[0048] Table 1 shows the positive electrode unsaturation of lithium-ion batteries under different low-temperature environments, that is, the amount of lithium released from the negative electrode;

[0049] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com