Dispensing method for LC-type optical fiber connector

A fiber optic connector and optical connector technology, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of deviation, inability to concentric the tail handle contour circle, etc., and achieve the effect of smooth entry and exit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

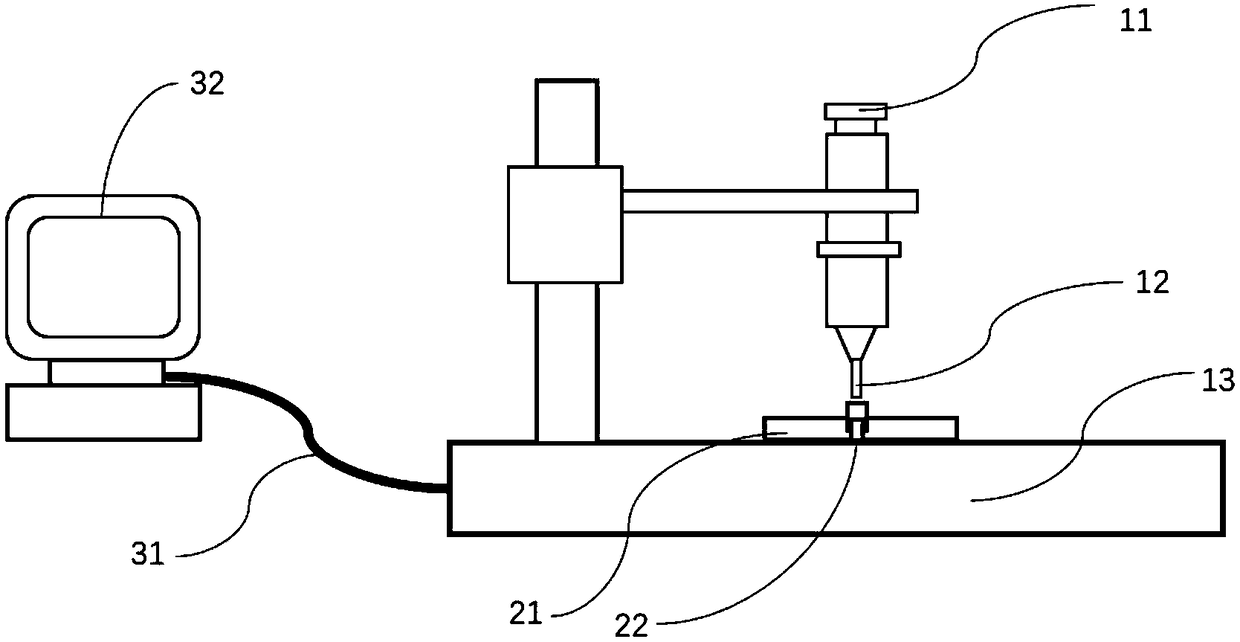

[0040] Such as figure 1 As shown, a dispensing machine is provided, including: a dispensing cylinder 11, a connector fixing fixture 21, a dispensing machine base 13, a control computer 32, and a communication cable 31;

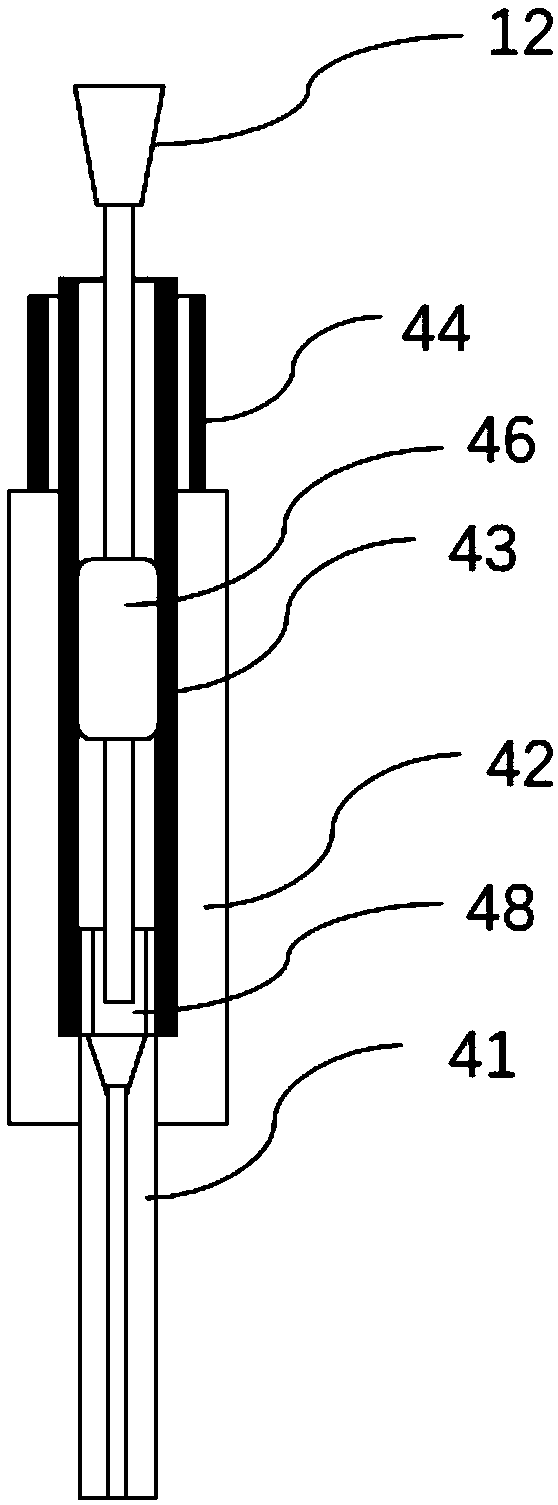

[0041] Further, a flexible dispensing needle 12 is provided, and the flexible needle is installed on the dispensing cylinder 11;

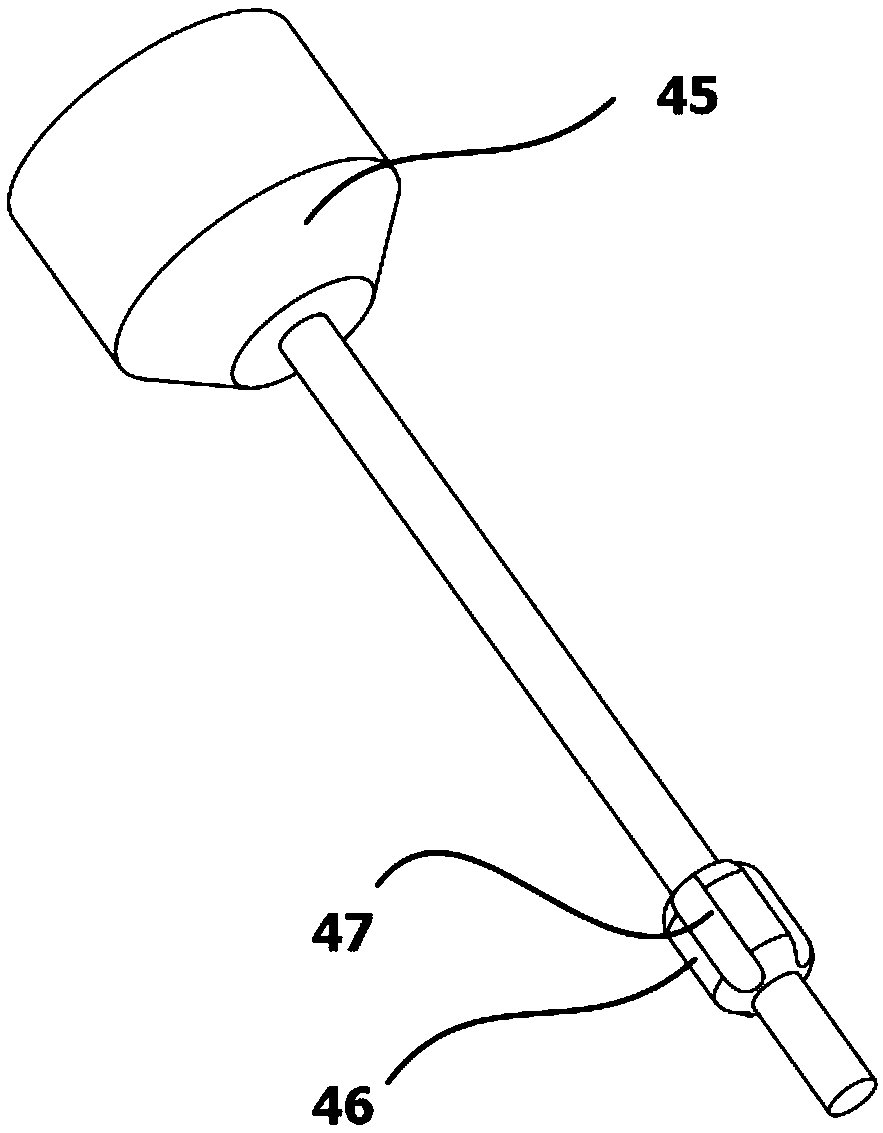

[0042] Further, such as image 3 As shown, a guide 46 is installed on the flexible needle 12;

[0043] Further, an LC type optical fiber connector 22 is provided;

[0044] Further, the LC type optical fiber connector 22 is installed on the dispensing base 13 through the connector fixing fixture 21;

[0045] Further, the position of the tail sleeve 43 on the LC-type optical connector 22 is determined by mechanically adjusting the positioning or optical positioning and shooting in advance;

[0046] Further, the glue dispenser is controlled by a control system preinstalled in the control computer 32 .

[0047] Further, control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com