An optimal control method for an open circulating water cooling end system

An optimized control, open cycle technology, applied in the field of circulating water system, can solve the problem of not considering the reliability of equipment operation, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

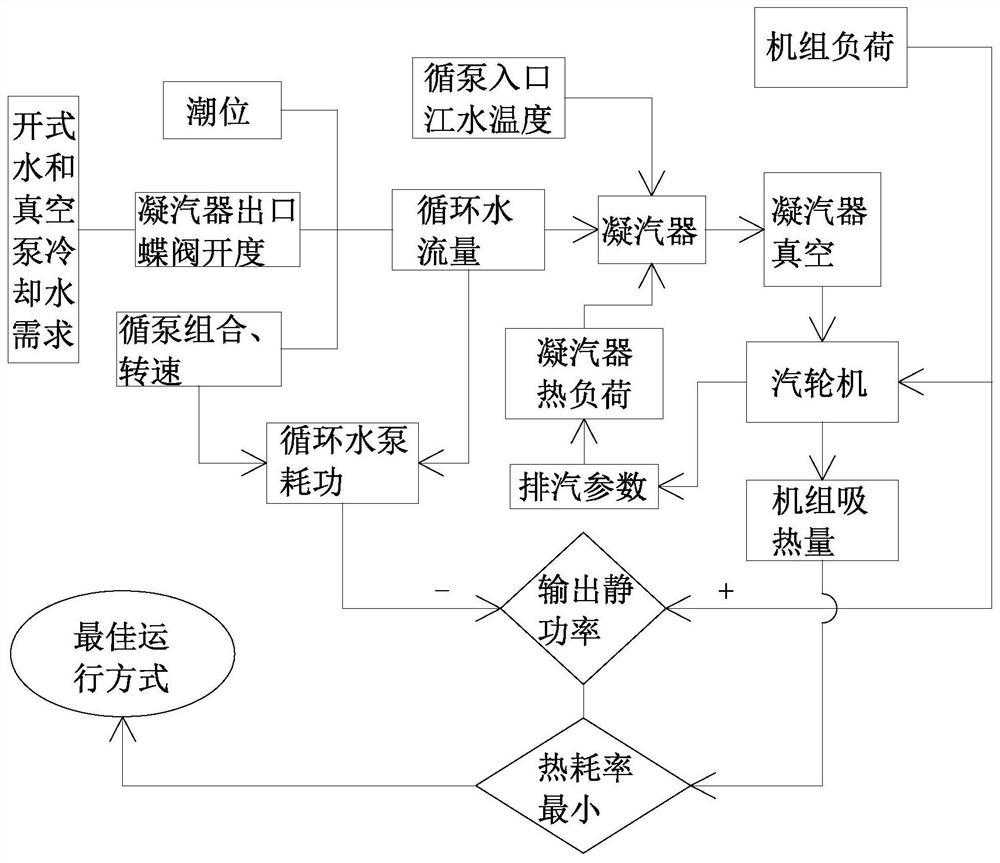

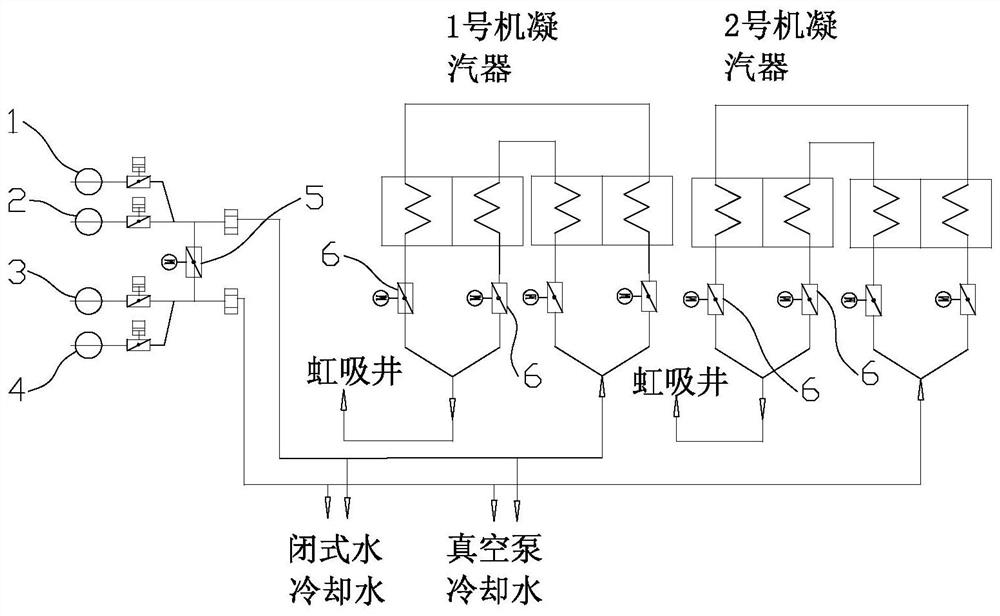

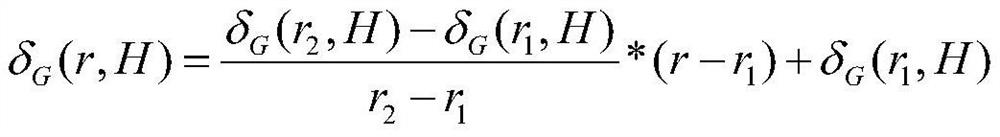

[0029] like Figure 1~2 As shown, a method for optimal control of an open circulating water cooling end system, the configuration of the open circulating water cooling end system involved in the control method in this embodiment is as follows figure 2 As shown, according to the circulating cooling water demand of a thermal power plant, each generator set is equipped with 4 variable speed circulating water pump sets. And the frequency conversion circulating water pump group D4; each variable frequency circulating water pump group is a variable speed circulating water pump, with a motor and a corresponding circulating water pump, changing the speed of the circulating water pump is by adding a frequency conversion device at the motor end to change the motor speed, or by adding a frequency conversion device at the motor end to change the motor spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com