Thermal battery cell based on embedded current collector plate composited FexNi<1-x>S2 cathode

A fexni1-xs2 single battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of battery short circuit, unprotected electrolyte layer, potential safety hazards, etc., to improve capacity decay and reduce internal resistance of single battery , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

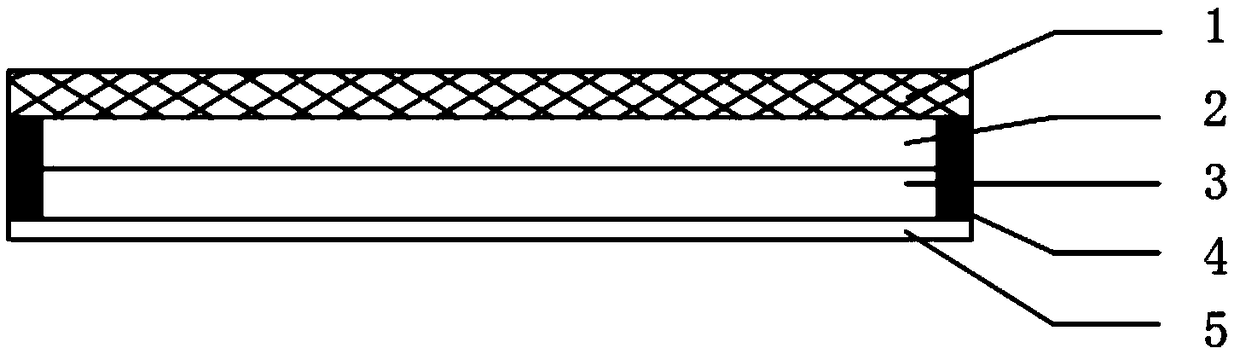

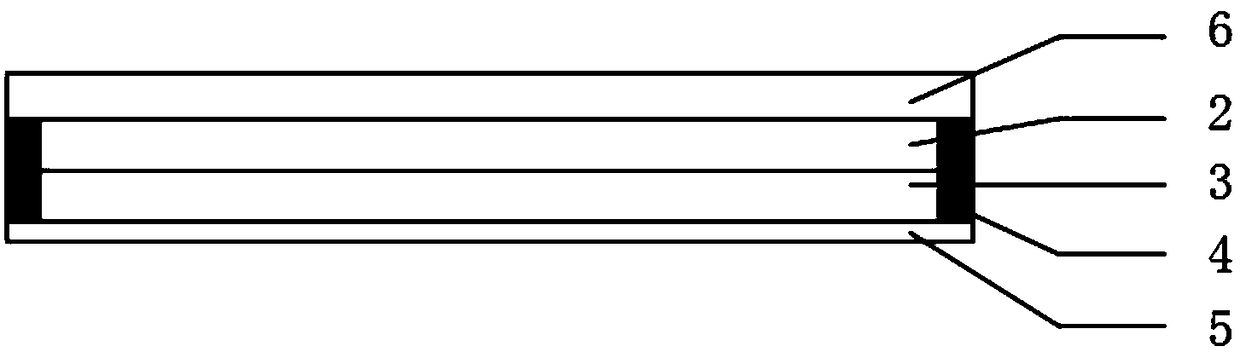

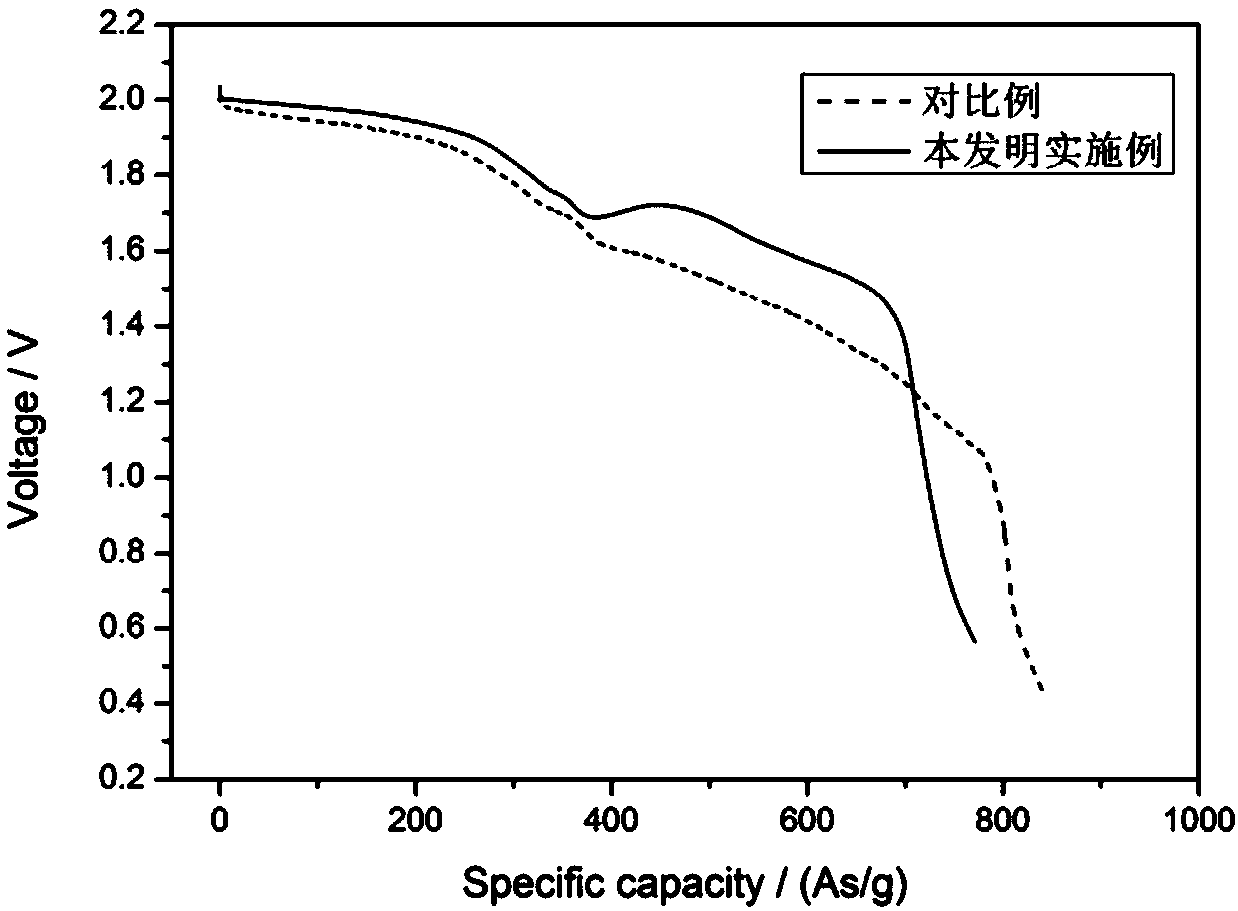

[0037] Embodiment 1 is based on the embedded current collector composite Fe 0.5 Ni 0.5 S 2 Positive thermal battery cell

[0038] (1) Fe 0.5 Ni 0.5 S 2 Preparation of positive electrode powder

[0039] 1. NiS 2 , FeS 2 , Li 2 Vacuum drying treatment of O and eutectic salts

[0040] (1)NiS 2 Vacuum drying: the NiS 2 Put it into a vacuum drying oven for drying, the drying temperature is 120±10°C, the relative vacuum degree is ≤-0.09Mpa, and the drying time is 6 hours.

[0041] (2) FeS 2 Vacuum drying: the NiS 2 Put it into a vacuum drying oven for drying, the drying temperature is 120±10°C, the relative vacuum degree is ≤-0.09Mpa, and the drying time is 6 hours.

[0042] (3) Li 2 O vacuum drying: the Li 2 O is dried in a vacuum drying oven, the drying temperature is 120±10°C, the relative vacuum degree is ≤-0.09Mpa, and the drying time is 6 hours.

[0043] (4) Vacuum drying of eutectic salt: Put the binary electrolyte LiCl-KCl (composed of 45wt% anhydrous LiCl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com