Hydrophobic three-dimensional porous material, preparation method and application thereof and blood storage bag

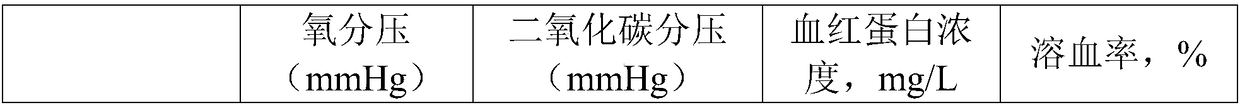

A three-dimensional porous and hydrophobic technology, applied in the field of medical equipment, can solve the problems of high requirements for preparation technology, harm of organic solvents, expensive preparation equipment, etc., and achieves the effects of simple operation, reduced carbon dioxide partial pressure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a hydrophobic three-dimensional porous material, the method comprising:

[0029] (1) Prepare a porous structure sugar template by using water-soluble sugar;

[0030] (2) Pouring polydimethylsiloxane into the sugar template with a porous structure and solidifying it;

[0031] (3) removing the porous structure sugar template in the solid material obtained in step (2).

[0032] According to the present invention, preferably, the solubility of the water-soluble sugar in water at 25° C. is 1.9-2.1 g sugar / g water, more preferably 1.95-2.05 g sugar / g water.

[0033] According to the present invention, preferably the water-soluble sugar is sucrose. In order to further control the pore structure of the hydrophobic three-dimensional porous material, preferably the water-soluble sugar contains coarse sugar and raffinose.

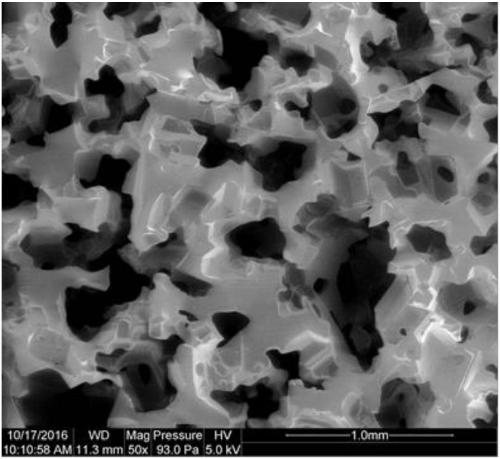

[0034] In the present invention, preferably, the particle size of the coarse granulated sugar is 300-1250 μm, and the particle size o...

Embodiment approach

[0043] According to a preferred embodiment of the present invention, the contacting is carried out under the second vacuum condition, the contacting time is 7-17 hours, and the contacting temperature is 10-20°C.

[0044] Among the present invention, the first vacuum is used to extract the air bubbles in the polydimethylsiloxane and curing agent; the second vacuum is used to remove the air bubbles in the porous structure sugar template, and is convenient for the polydimethylsiloxane to enter In the pores of the porous structure sugar template.

[0045] According to the present invention, preferably, the mass ratio of polydimethylsiloxane to water-soluble sugar is 1-3:1, more preferably 1.5-2.5:1, even more preferably 1.5-2:1. Adopting the preferred embodiment of the present invention is more conducive to the formation of irregular pore structures in hydrophobic three-dimensional porous materials.

[0046]The specific implementation of the step (2) of the present invention may ...

preparation example 1

[0077] (1) Preparation of porous structure sugar template

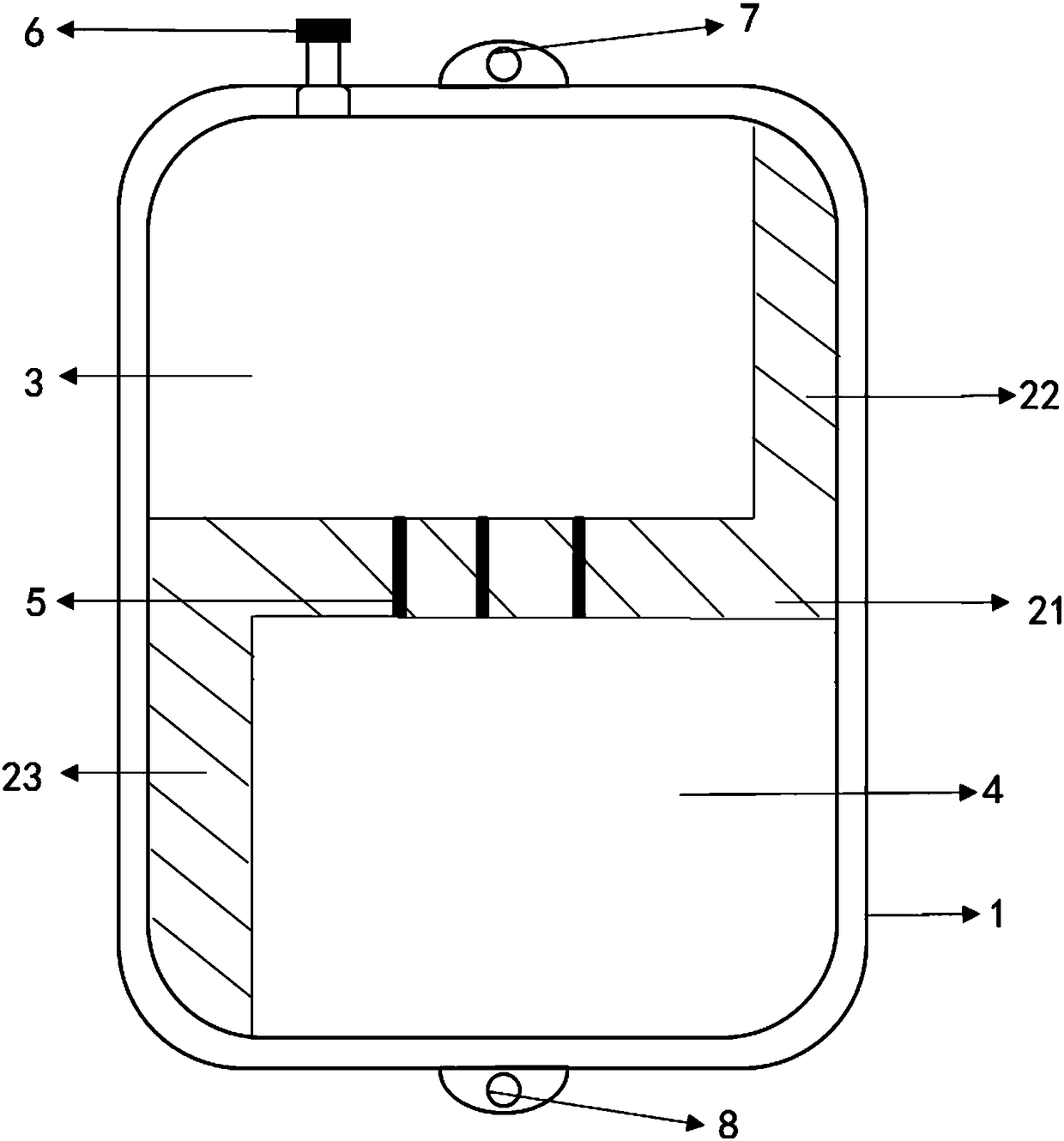

[0078] Take 30g of coarse granulated sugar and 70g of cotton white sugar and mix in a beaker, add deionized water according to the ratio of 100g of water-soluble sugar (the total mass of coarse granulated sugar and cotton white sugar) to 1mL of deionized water and mix evenly; pour the mixed material into the mold (Self-made Z-type PMMA mold, specific as figure 2 The shape of the filter element in the blood storage bag shown, the same below), and press the mold tightly; put the mold in an oven, and heat it at 80°C for 1 hour; after cooling to room temperature, put the mold containing the porous sugar template in a vacuum in a vacuum device;

[0079](2) Infusion of polydimethylsiloxane

[0080] Polydimethylsiloxane (150g) is mixed with curing agent in a mass ratio of 10:1, and then vacuumized for 30min to remove air bubbles to obtain a mixture, which is all poured into a mold filled with a porous structure sugar temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com