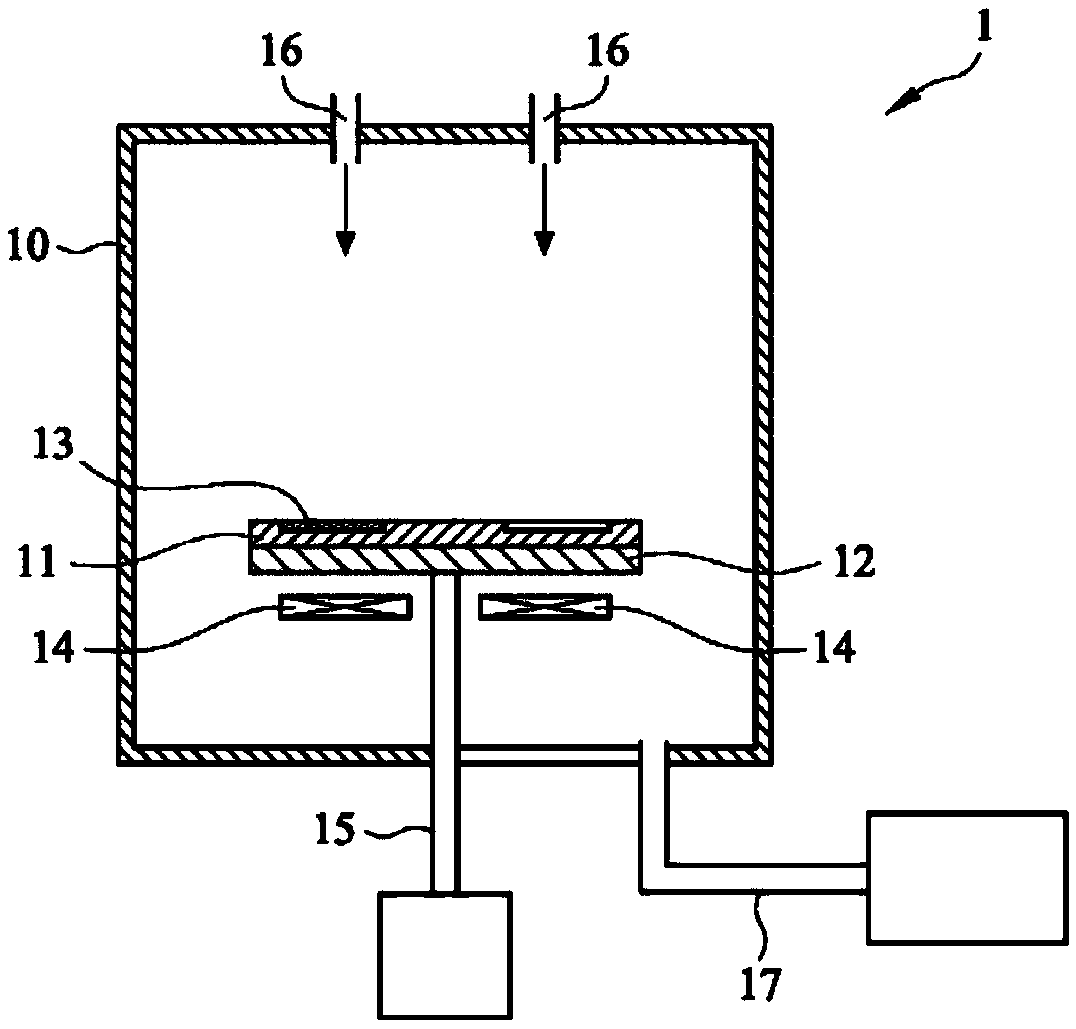

Chemical vapor deposition system

A chemical vapor deposition, wafer carrying technology, applied in the direction of chemical reactive gas, gaseous chemical plating, chemical instruments and methods, etc., can solve the problems of inability to deposit thin films and lowering yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

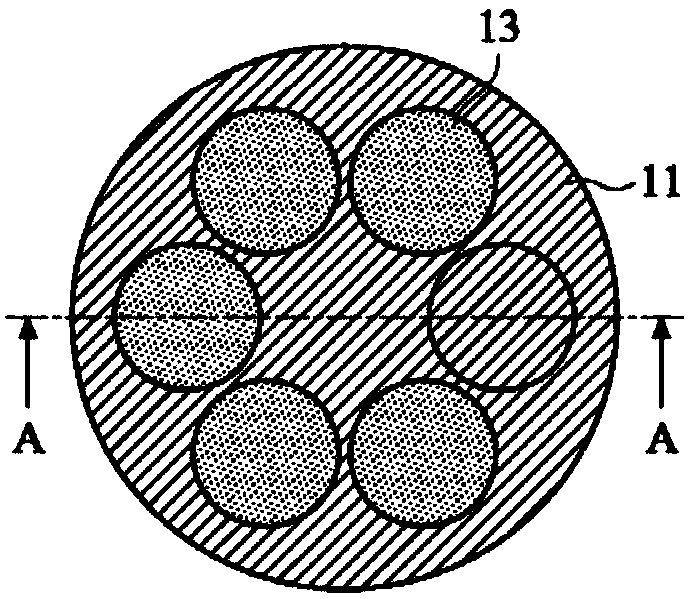

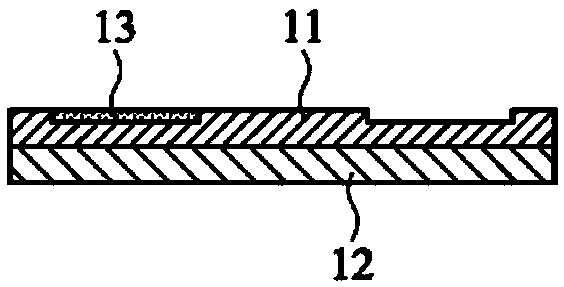

Embodiment Construction

[0063] Various embodiments of the present application will be described in detail below, and the accompanying drawings are used as examples. In some embodiments, the examples shown in the figures may be to scale, but in other embodiments, not necessarily to scale. In some embodiments, the same or similar reference numerals may represent the same, similar, or analogous elements and / or elements, but in some embodiments, may also represent different elements. In some embodiments, nouns describing directions may be interpreted literally, but in other embodiments, they may not be interpreted literally. In addition, in order to clearly show certain elements of the present invention, some elements may be omitted in the illustrations. In the description of the specification, many specific details are provided in order to enable readers to have a more complete understanding of the present invention; however, the present invention may still be practiced under the premise of omitting so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com