Processing method of enhancing and recycling waste wrapping paper

A processing method and wrapping paper technology, applied in waste paper processing, recycling technology, papermaking, etc., can solve problems such as improper handling, high recycling requirements, and reduced paper strength, so as to improve safety, enhance use value, The effect of promoting mutual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

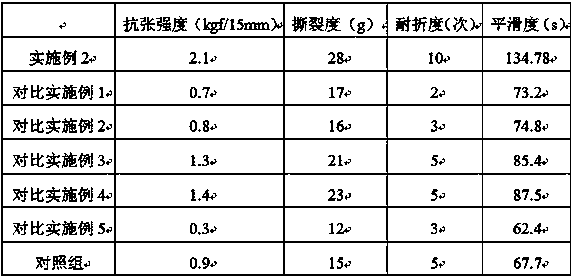

Examples

Embodiment 1

[0033] A processing method for enhanced reuse of waste wrapping paper, comprising the following steps:

[0034] (1) Crushing treatment:

[0035] Put the bactericide and waste packaging paper into the cryogenic pulverizer according to the volume-to-weight ratio of 1mL:23g, and take out the waste paper powder after pulverization for 30 minutes;

[0036] (2) Deinking treatment:

[0037] Put the waste paper powder and deinking agent obtained in step (1) into the purification tank according to the weight volume ratio of 1g:2mL and then stir them. When stirring and deinking, use microwave heating to keep the temperature in the purification tank at 50°C, and then stir After 1h, filter waste paper raw materials;

[0038] (3) Weighing of raw materials:

[0039] Weigh the following raw materials according to the corresponding parts by weight: 60 parts of waste paper raw materials obtained in step (2), 23 parts of biomass fiber, 24 parts of composite filler, 4 parts of starch, 3 parts...

Embodiment 2

[0058] A processing method for enhanced reuse of waste wrapping paper, comprising the following steps:

[0059] (1) Crushing treatment:

[0060] Put the bactericide and waste packaging paper into the cryogenic pulverizer according to the volume-to-weight ratio of 1mL:24g, and take out the waste paper powder after pulverization for 35 minutes;

[0061] (2) Deinking treatment:

[0062] Put the waste paper powder and deinking agent obtained in step (1) into the purification tank according to the weight volume ratio of 1g:2.5mL and then stir them. When stirring and deinking, use microwave heating to keep the temperature in the purification tank at 54°C, and stir After 1.5 hours of treatment, filter waste paper raw materials;

[0063] (3) Weighing of raw materials:

[0064] The following raw materials were weighed in corresponding parts by weight: 65 parts of waste paper raw materials obtained in step (2), 25 parts of biomass fiber, 25 parts of composite filler, 4.5 parts of sta...

Embodiment 3

[0083] A processing method for enhanced reuse of waste wrapping paper, comprising the following steps:

[0084] (1) Crushing treatment:

[0085] Put the fungicide and waste wrapping paper into the cryogenic pulverizer according to the volume-to-weight ratio of 1mL:25g, and take out the waste paper powder after pulverizing for 40 minutes;

[0086] (2) Deinking treatment:

[0087] Put the waste paper powder and deinking agent obtained in step (1) into the purification tank according to the weight volume ratio of 1g:3mL and then stir them. When stirring and deinking, use microwave heating to keep the temperature in the purification tank at 58 °C, and then stir. After 2h, filter waste paper raw material;

[0088] (3) Weighing of raw materials:

[0089] Weigh the following raw materials according to the corresponding parts by weight: 70 parts of waste paper raw materials obtained in step (2), 27 parts of biomass fiber, 26 parts of composite filler, 5 parts of starch, 5 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com