Measurement method and device of specific volume of steamed bread

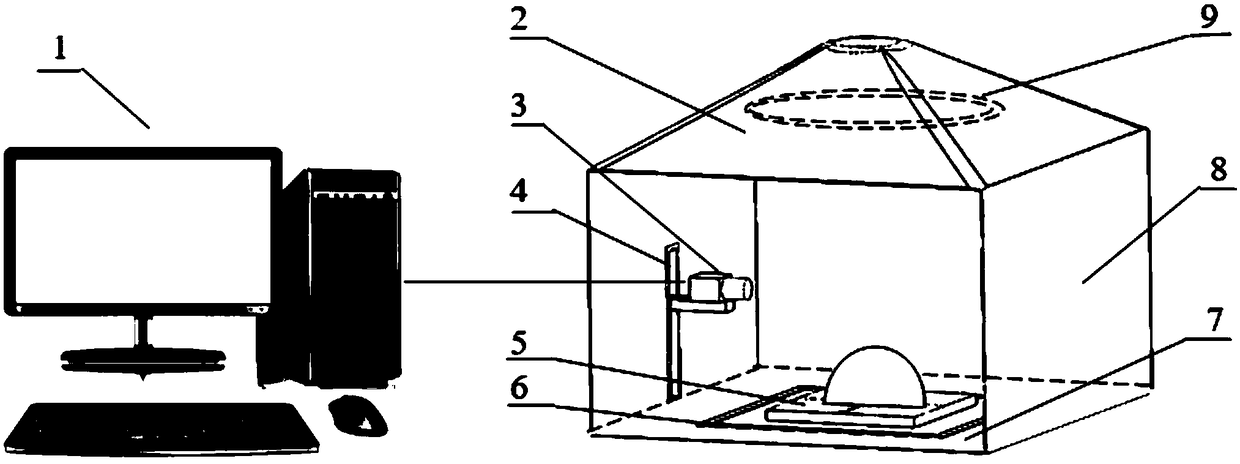

The technology of a measuring device and a measuring method, which is applied in the direction of measuring device, specific gravity measurement, using optical device, etc., can solve the problems of difficult on-line detection and complicated operation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

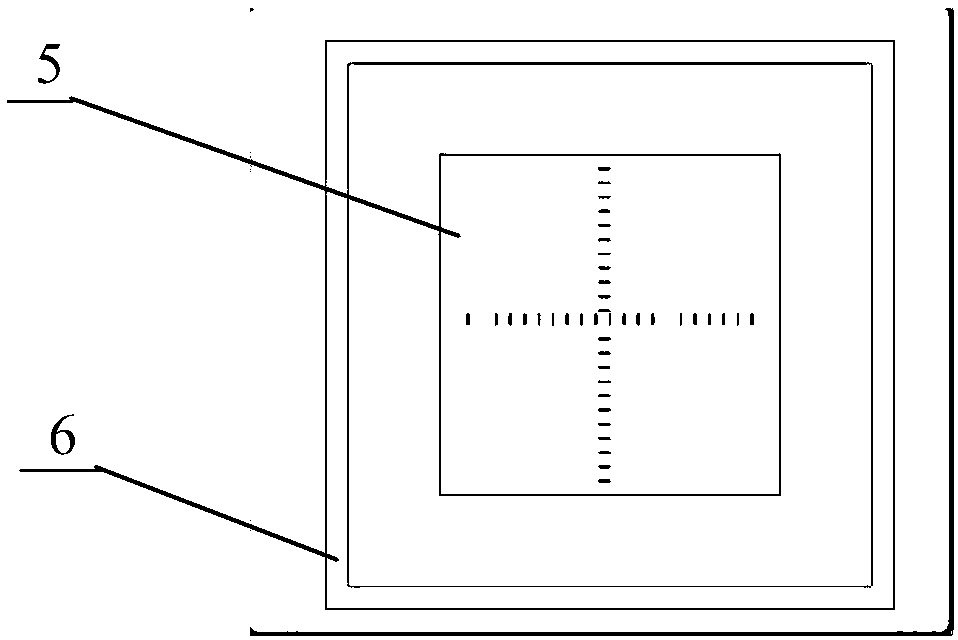

[0037] First turn on the LED light sources 6 and 9, adjust to a suitable brightness, turn on the switch of the camera, and then put a steamed bun with a weight of 50.4g on the stage 5 in the light chamber 2. Align the origin of the upper "ten" coordinates, adjust the height of the industrial camera 3 through the guide rail 4, make the center of the camera lens align with the geometric center of the side of the steamed bun, manipulate the camera, and extract the side image of the steamed bun.

[0038] Import the obtained image into the Halcon software, intercept the "ten"-shaped coordinates on the stage 5 on the image, each 5cm from the left and right of the origin of the abscissa axis, that is, the standard length of the interception is L=10cm, and measure the pixel size L of L on the image '=1770, so the conversion factor between the pixel size and the actual size is: k=L / L'=10 / 1770=0.0056.

[0039] In the software, the image text is segmented under the threshold value of the...

Embodiment 2

[0045] Put a steamed bun with a weight of 99.8g on the stage 5 of the light chamber 2 that has been set up in Case 1, and adjust the height of the industrial camera 3 through the guide rail 4, so that the center of the camera lens is aligned with the geometric center of the side of the steamed bun. Extract the silhouette of the steamed bun. Since the distance between the camera and the stage does not change, the conversion factor between the pixel size and the actual size is the same as that of Embodiment 1, which is: k=L / L'=10 / 1770=0.0056. The steamed bun silhouette is still segmented under the R channel, and the threshold range is [0,53].

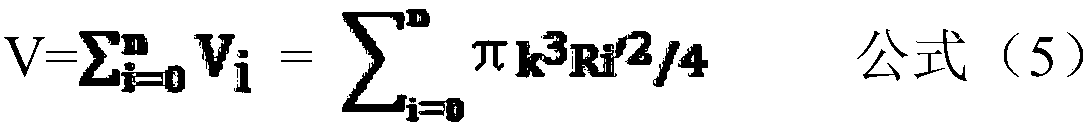

[0046] According to formula 4, it can be concluded that the volume of each pixel cylinder is:

[0047] V i = πr i 2 h i = πk 3 R i ' 2 / 4=1.76×10 -7 ×π×R i ' 2 / 4=4.4×10 -6 ×πR i ' 2

[0048] It can be read from the software that the pixel height (number of layers) of the steamed bun is 870, and the diameter of the cylinder...

Embodiment 3

[0051] Put a steamed bun with a weight of 151.2g on the stage 5 of the light chamber 2 that has been set up in Case 1, and adjust the height of the industrial camera 3 through the guide rail 4, so that the center of the camera lens is aligned with the geometric center of the side of the steamed bun. Extract the silhouette of the steamed bun. Since the distance between the camera and the stage does not change, the conversion factor between the pixel size and the actual size is the same as that of Embodiment 1, which is: k=L / L'=10 / 1770=0.0056. The steamed bun silhouette is still segmented under the R channel, and the threshold range is [0,53].

[0052] According to formula 4, it can be concluded that the volume of each pixel cylinder is:

[0053] V i = πr i 2 h i = πk 3 R i ' 2 / 4=1.76×10 -7 ×π×R i ' 2 / 4=4.4×10 -6 ×πR i ' 2

[0054] It can be read from the software that the pixel height (number of layers) of the steamed bun is 995, and the diameter of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com