Integrated railway signal relay life test device and method

A railway signal and relay technology, applied in the field of integrated railway signal relay life test device, can solve the problems of not being able to meet the test requirements well, prone to errors, complicated operation, etc., so as to achieve strong anti-interference ability of the device and safe and reliable work. , the effect of simplifying the test procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

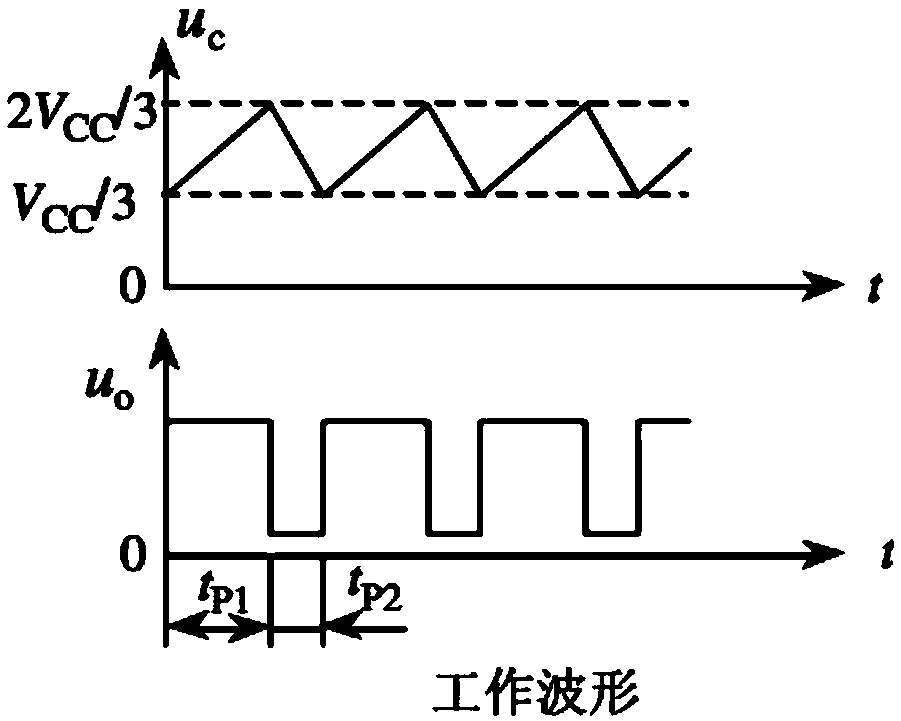

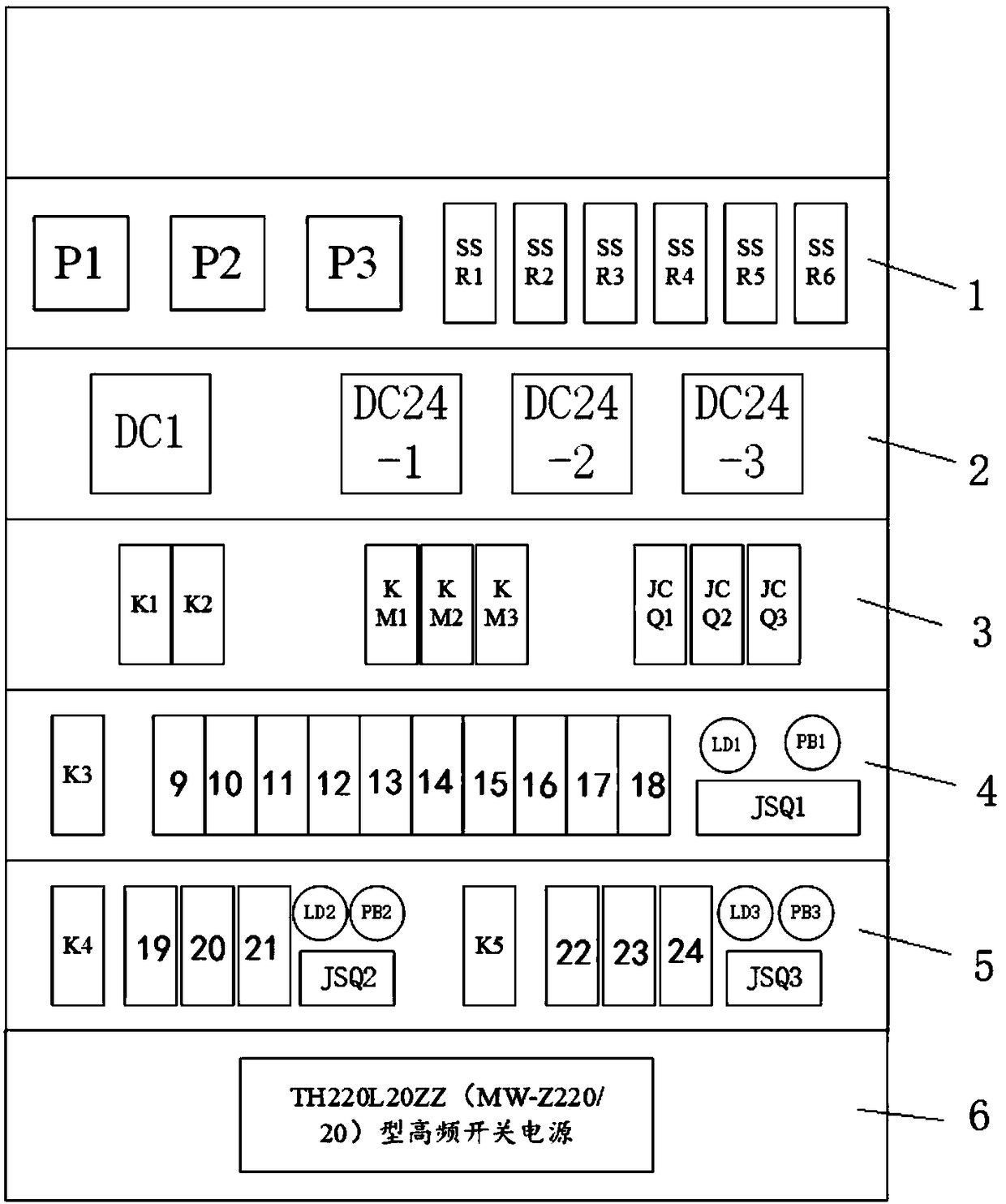

[0080] Example 1: Figure 2 (a), Figure 2 (b), image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Picture 9 As shown, an integrated railway signal relay life test device is divided into control circuit equipment and load circuit equipment. The control circuit equipment makes the sample relay operate at the specified frequency, and the load circuit equipment applies the standard required voltage and current to the sample relay contact. .

[0081] Control circuit equipment includes:

[0082] (1) Control working layer 1: The first single-chip microcomputer P1, the second single-chip P2, and the third single-chip P3 form a single-chip control group. The models of the first single-chip P1, the second single-chip P2 and the third single-chip P3: PIC18F45K80 are responsible for controlling the sample relay The ratio of operating frequency and on-off time.

[0083] The first single-chip P1, the second single-chip P2, and the third single-chip P3 enter 4-segment codes, ...

Embodiment 2

[0108] Example 2: As shown in Figure 2(a) and Figure 2(b), an integrated railway signal relay life test device is divided into control circuit equipment and load circuit equipment. The control circuit equipment makes the sample relay follow the specified frequency Action, the load circuit equipment applies the voltage and current required by the standard to the sample relay contacts.

[0109] The control circuit equipment includes a control working layer 1, a power supply layer 2, a switch layer 3, a mechanical life test layer 4, an electrical life test layer 5, and a load power supply layer 6. The load circuit equipment includes a load resistance layer 7 and a fan layer 8.

[0110] The electrical life test layer 5 includes the first electrical life test layer (left side) and the electrical life test second layer (right side).

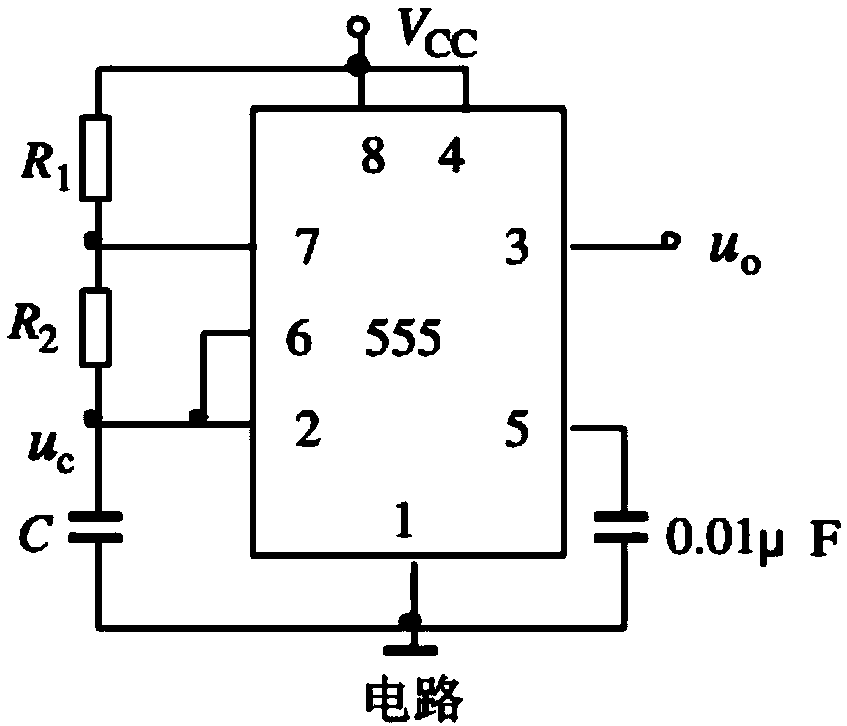

[0111] Such as image 3 As shown, the circuit breaker K2 is connected to AC220V city power and DC1 5V direct current. The first single-chip microcomputer P1 ...

Embodiment 3

[0125] Embodiment 3: An integrated railway signal relay life test method, including the following steps;

[0126] Step 1. Mechanical life test layer:

[0127] Switch on the main circuit breaker K2 of the control circuit equipment, and the first power module DC1 converts AC220V city power into DC5V direct current, which is used as the working power supply of the first single-chip microcomputer P1. According to the sample relay model, use the code selection switch to select the corresponding frequency mode, the first single-chip microcomputer P1 outputs the level signal of the corresponding frequency to the first solid state relay SSR1 coil. The second power supply module DC24-1 outputs DC24V, which is connected to the sample relay coil of the mechanical life test layer through the first solid state relay SSR1 contact, so that the sample relay operates at the specified frequency.

[0128] Step 2. The first layer of the electrical life test of the electrical life test layer 5:

[0129] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com