A kind of antipyretic patch and preparation method thereof

An antipyretic paste and antipyretic technology, applied in the field of medical products, can solve the problems of allergies, the discoloration of the hydrogel layer is not easy, and the process complexity is increased, and the effect of achieving integrity, good bacteriostatic and insecticidal effects can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

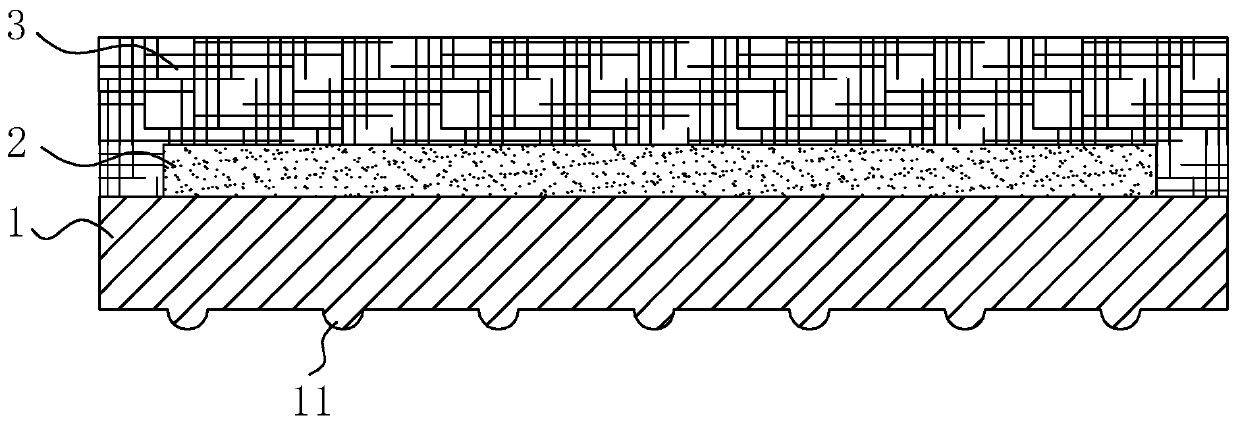

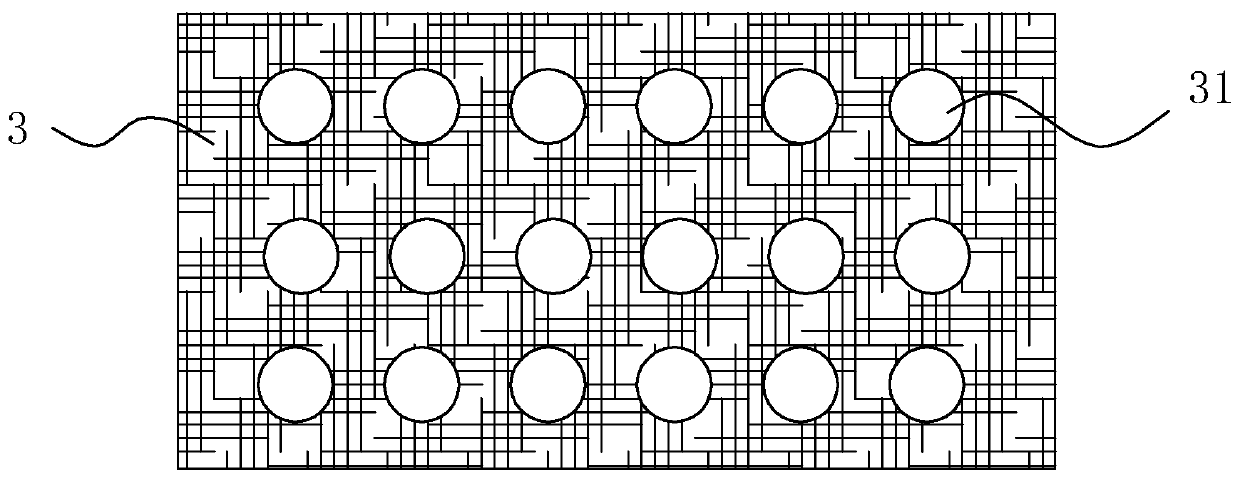

[0045] An antipyretic patch combined with an attached figure 1 And attached figure 2As shown, from the inside to the outside are the antipyretic gel layer 1, the thermochromic layer 2 and the protective layer, wherein the protective layer is a transparent film layer 3, and in order to improve the effect of heat dissipation, the surface of the film layer 3 is also provided with A number of pores 31 are beneficial for the heat generated by the human body to dissipate from the pores 31 . The temperature-sensitive color-changing layer 2 is mixed with the color-changing material indoline and polyurethane with a mass ratio of 1:3, which helps the temperature-sensitive color-changing layer 2 and the film layer 3 and the heat-relieving gel layer 1. Bonds effectively. Therefore, when the temperature of the human body exceeds 38.5 degrees, the temperature-sensing and coloring mechanism of the thermochromic layer 2 will take effect, and the preset pattern will be displayed. In additi...

Embodiment 2

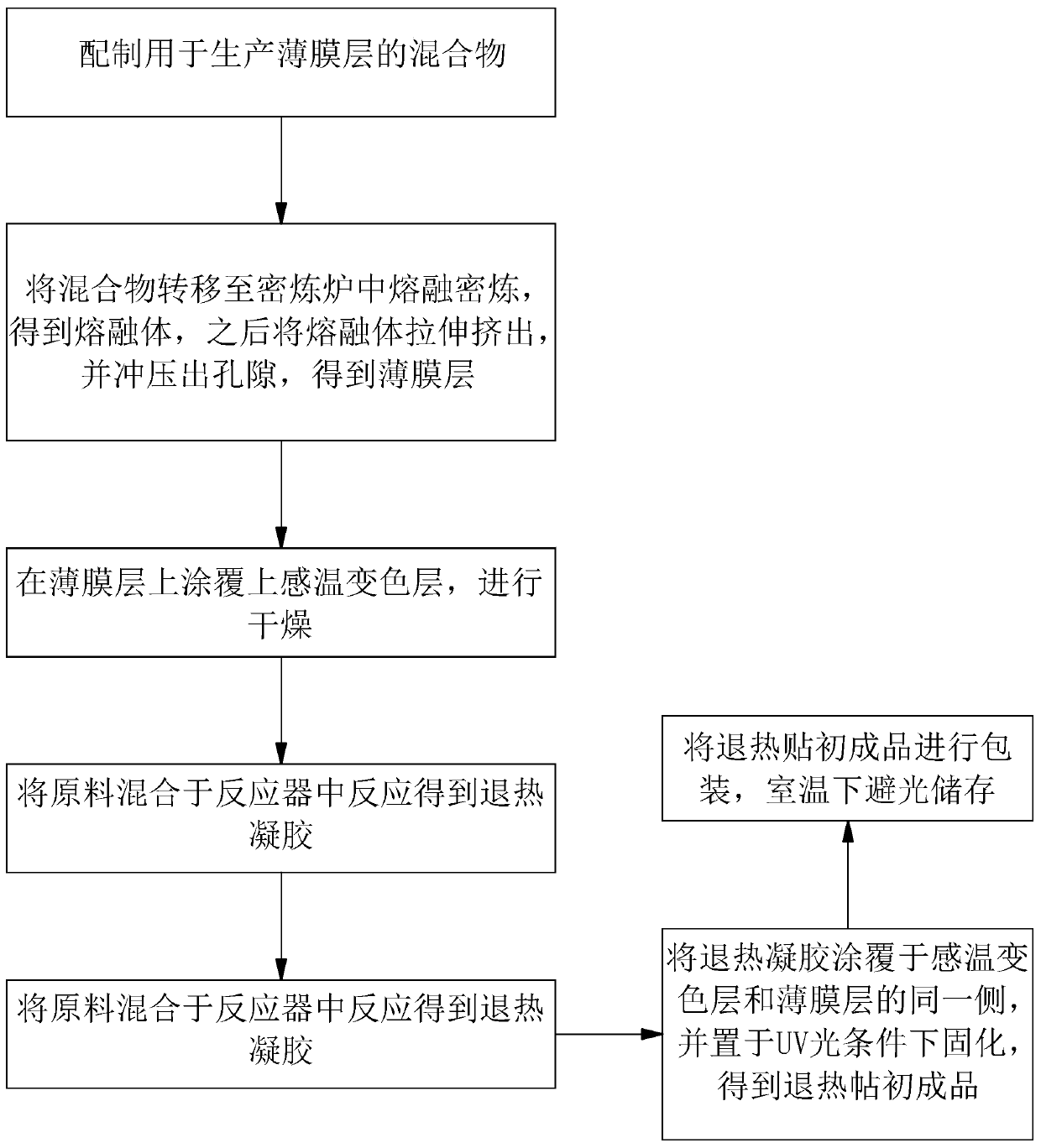

[0049] A kind of preparation method of antipyretic patch, as attached image 3 shown, including the following steps:

[0050] a. Weigh 65Kg of polyvinyl alcohol and 4Kg of glutaraldehyde into the mixer, mix at a stirring speed of 100rpm, then weigh 8Kg of glycerin, 3Kg of sodium hydroxide, 5.4Kg of carbonamide, 3Kg of calcium chloride, and 4Kg of Add coral powder, 10Kg 2-acrylamide-2-methylpropanesulfonic acid, 2Kg anionic surfactant and 45Kg water into the mixer, and mix again at a stirring speed of 200rpm to obtain a mixture;

[0051] b. Put the mixture into a banburying furnace, raise the temperature to 230°C for melting and banburying, and obtain a molten body, transfer the molten body to an extruder for stretching and extrusion, obtain a film layer 3 after cooling, and use The punching machine punches out several pores 31 on the film layer 3;

[0052] c. On the film layer 3, first coat the same thermochromic layer 2 as in Example 1, and fold the edge of the film layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com