Fluidized bed distributor for chlorothalonil production

A technology of fluidized bed reactors and distributors, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., to achieve the effects of improving fluidization state, improving reaction stability, and avoiding excessive reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

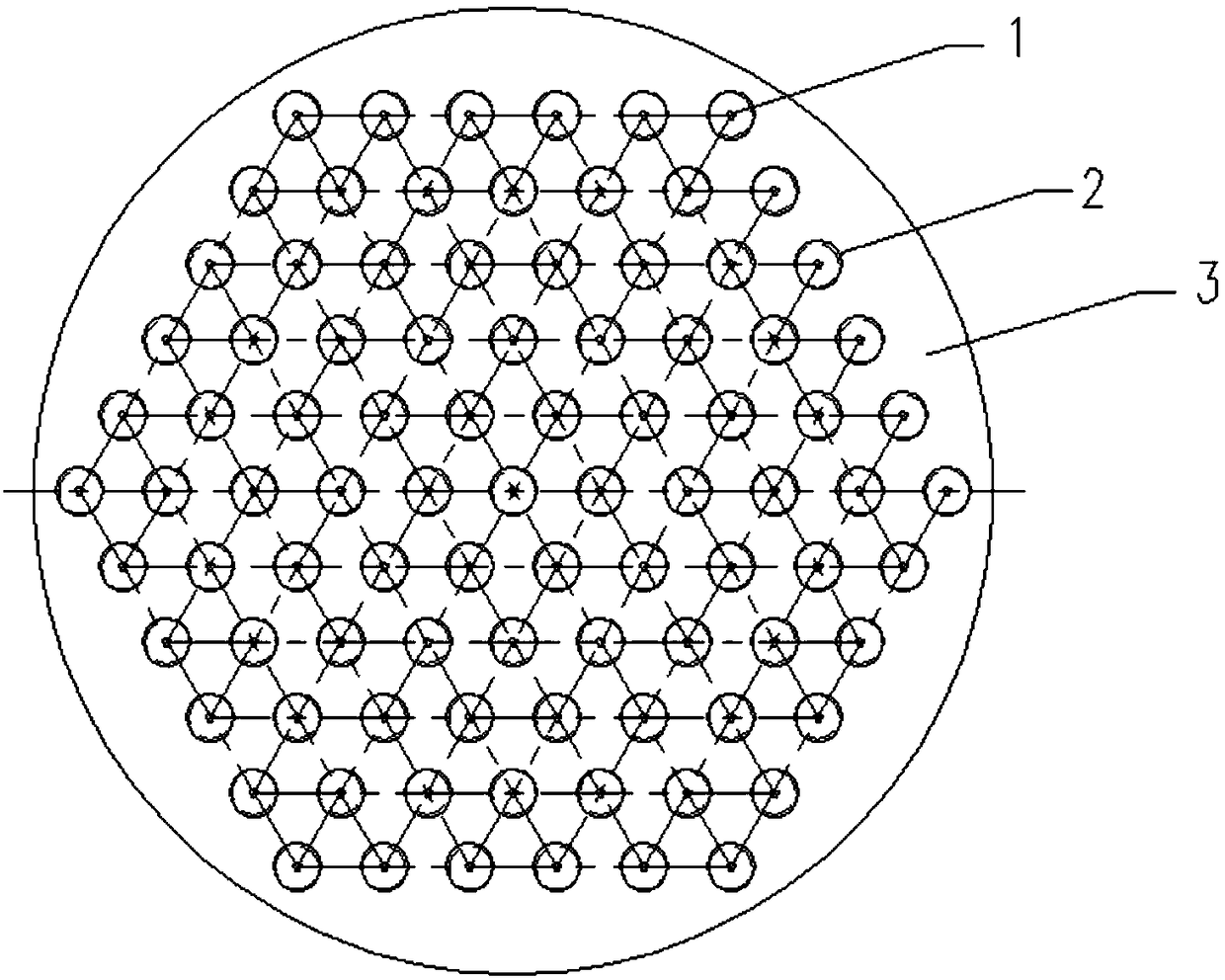

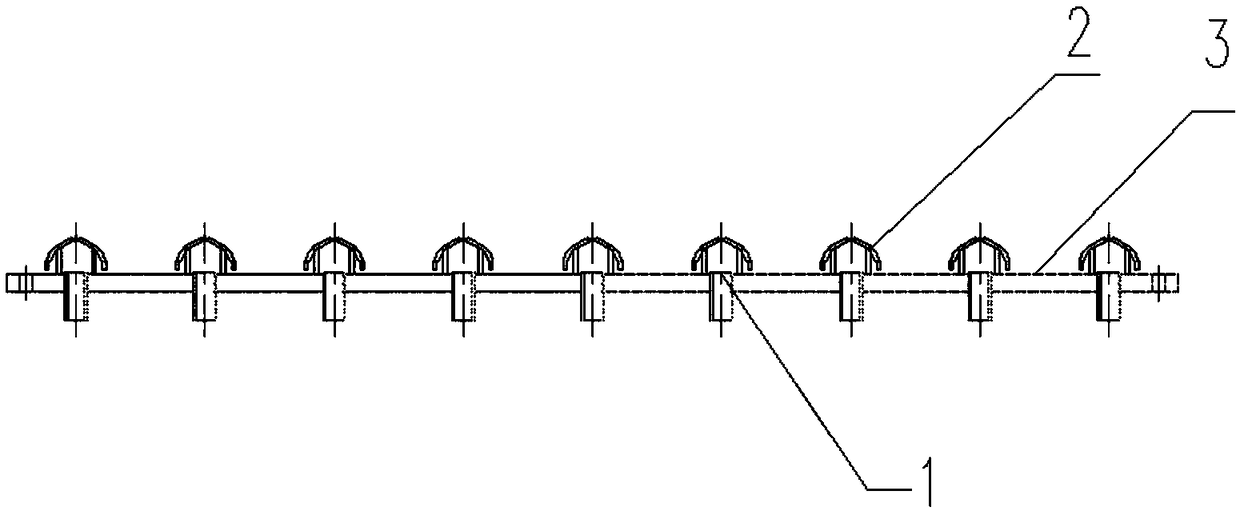

[0047] This embodiment provides a fluidized bed distributor for the production of chlorothalonil, the schematic diagram of the top view structure of the fluidized bed distributor is as follows figure 1 As shown, its partial side view is shown as figure 2 As shown, it includes a distribution plate 3 and an air cap 2. The distribution plate 3 is provided with a plurality of air holes 1, and each air hole 1 is correspondingly provided with an air cap 2. The air cap 2 is fixedly connected to the distribution plate 3. There is a gap between the edge of the gas cap 2 and the distribution plate 3; the opening ratio of the distribution plate 3 is 1.5%.

[0048] The distribution plate 3 is a circular plate with a diameter of 1000mm; the air holes 1 are arranged in an equilateral triangle on the distribution plate 3, the diameter of the air holes 1 is 12mm, and the distance between two adjacent air holes 1 is 100mm; The distribution plate 3 is provided with tubes, and the tubes corres...

Embodiment 2

[0051] This embodiment provides a fluidized bed distributor for the production of chlorothalonil. The fluidized bed distributor includes a distribution plate 3 and an air cap 2. A plurality of air holes 1 are provided on the distribution plate 3, each An air cap 2 is correspondingly arranged above the air hole 1, and the air cap 2 is fixedly connected to the distribution plate 3, and there is a gap between the edge of the air cap 2 and the distribution plate 3; the opening ratio of the distribution plate 3 is 0.5%. .

[0052] The distribution plate 3 is a circular plate with a diameter of 2000mm; the air holes 1 are arranged in an equilateral triangle on the distribution plate 3, the diameter of the air holes 1 is 20mm, and the distance between two adjacent air holes 1 is 160mm; The distribution plate 3 is provided with tubes, the tubes are respectively corresponding to the air holes 1, the upper end of the tubes is flush with the distribution plate 3, and the lower end passes...

Embodiment 3

[0055] This embodiment provides a fluidized bed distributor for the production of chlorothalonil. The fluidized bed distributor includes a distribution plate 3 and an air cap 2. A plurality of air holes 1 are provided on the distribution plate 3, each An air cap 2 is correspondingly provided above the air hole 1, and the air cap 2 is fixedly connected to the distribution plate 3, and there is a gap between the edge of the air cap 2 and the distribution plate 3; the opening rate of the distribution plate 3 is 3.2%. .

[0056] The distribution plate 3 is a circular plate with a diameter of 3000mm; the air holes 1 are arranged in an equilateral triangle on the distribution plate 3, the diameter of the air holes 1 is 25mm, and the distance between two adjacent air holes 1 is 200mm; The distribution plate 3 is provided with tubes, the tubes are respectively corresponding to the air holes 1, the upper end of the tubes is flush with the distribution plate 3, and the lower end passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com