Tool wear monitor method based on composite signal of multiple kinds of sensors

A tool wear and composite signal technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems such as complex models, a large number of experimental samples, and prone to over-learning phenomena, so as to improve efficiency and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

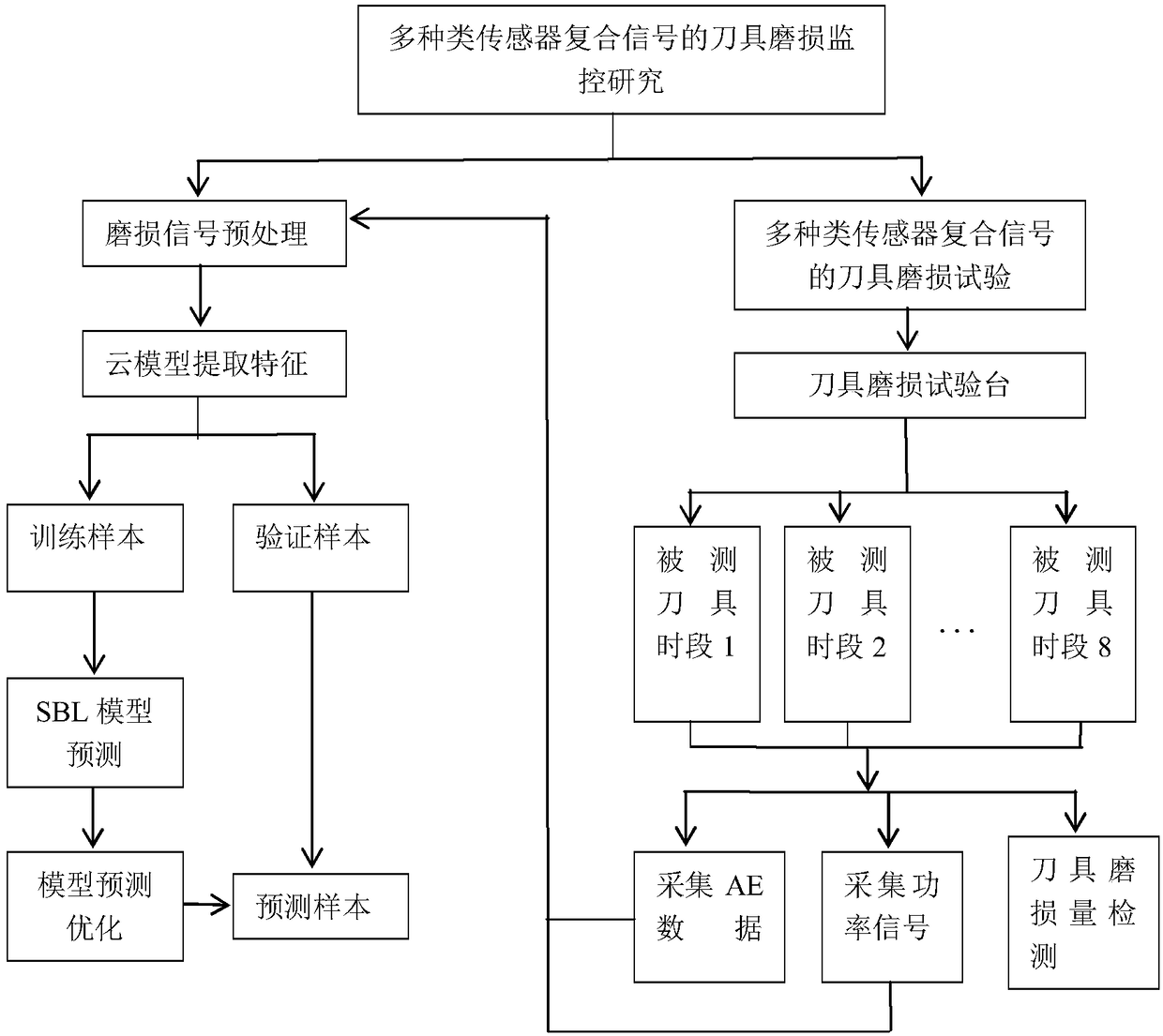

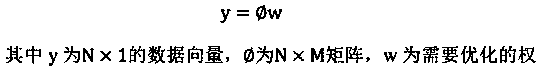

[0034] A tool wear monitoring method based on multiple types of sensor composite signals, comprising the following steps:

[0035] (1) Data collection: use the acoustic emission sensor to collect the acoustic emission signal of the machine tool, use the power sensor to collect the processing power signal of the machine tool, and use a microscope to take pictures of the tool after each processing period, and measure the tool flank wear value, Used for comparison to obtain tool wear data;

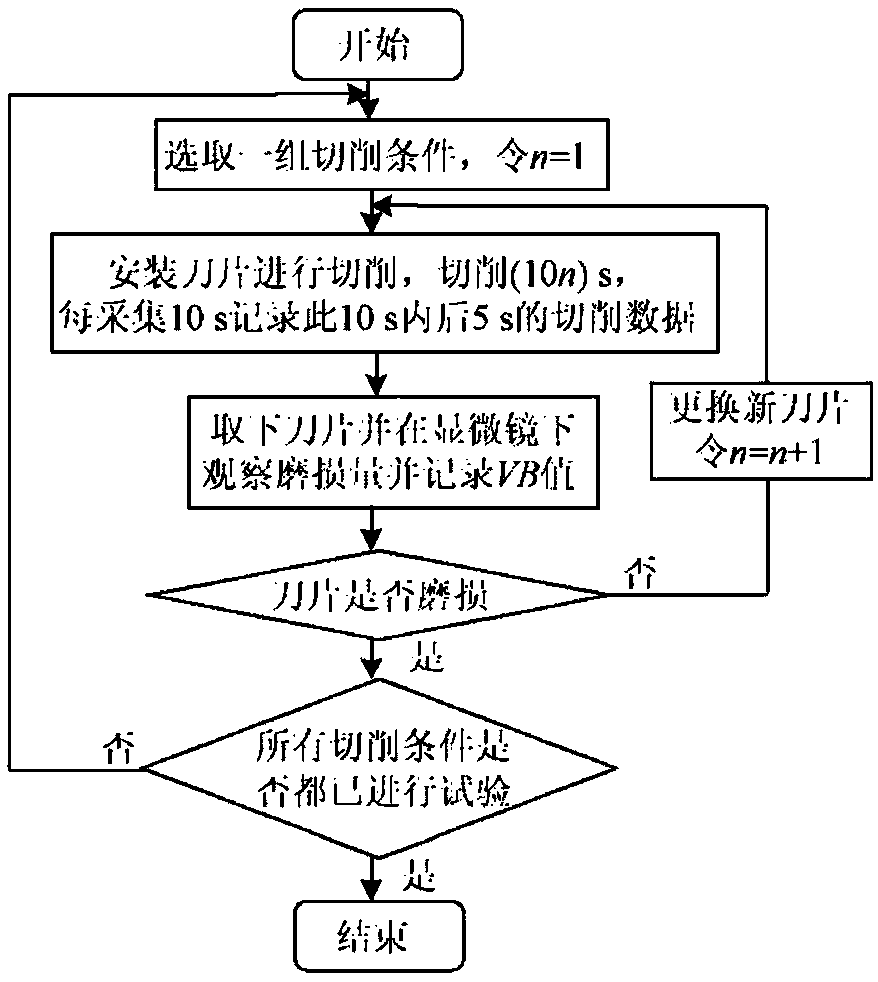

[0036] Specifically: under a certain working condition, a titanium alloy bar with a diameter of 110mm is processed, using a total of 8 tools of the same type (tool model: QNMG 090408-NF), and the acoustic emission sensor is fixed on the tool body of the test bench In the above, the multi-channel acoustic emission data acquisition system of PAC of the United States is used for data acquisition of acoustic emission signals and power signals. In order to better study the prediction of the relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com