Rapid die distribution device

A kind of moulding and rapid technology, applied in the direction of mould separation device, mould fixing device, mould auxiliary parts, etc., can solve the problems of many equipment, many production processes, low production efficiency, etc., to simplify the preparation process, speed up the moulding and dismantling. Mold speed, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

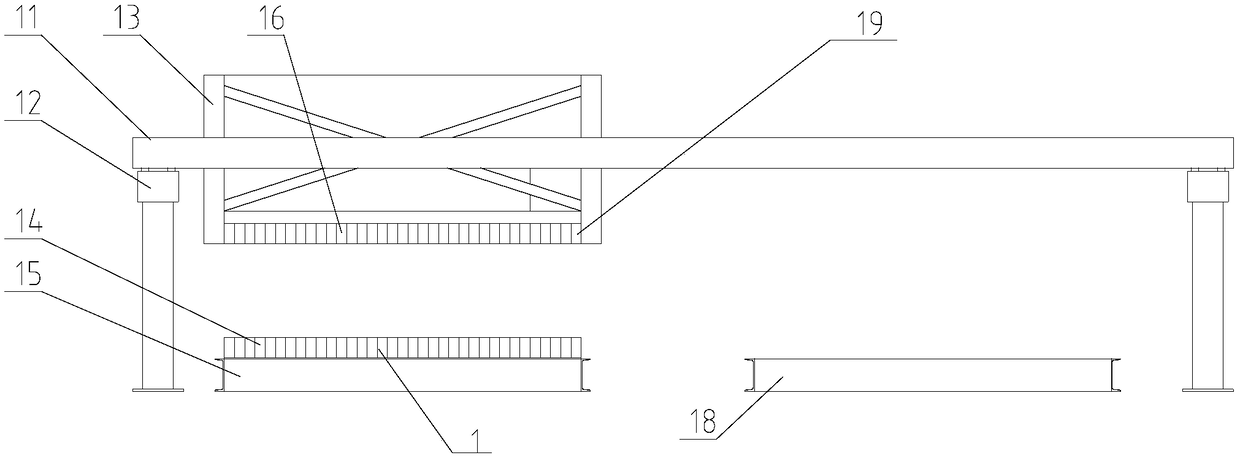

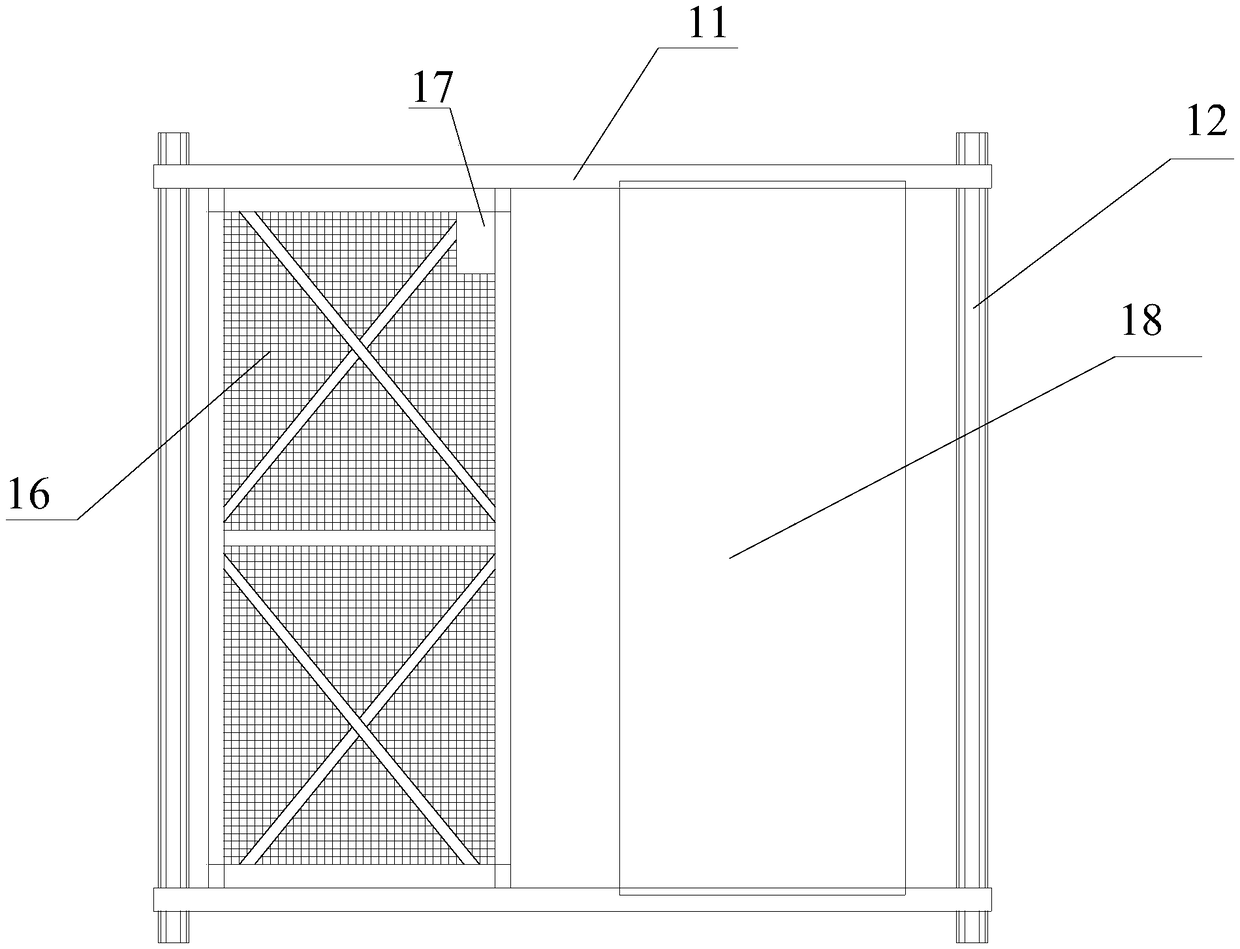

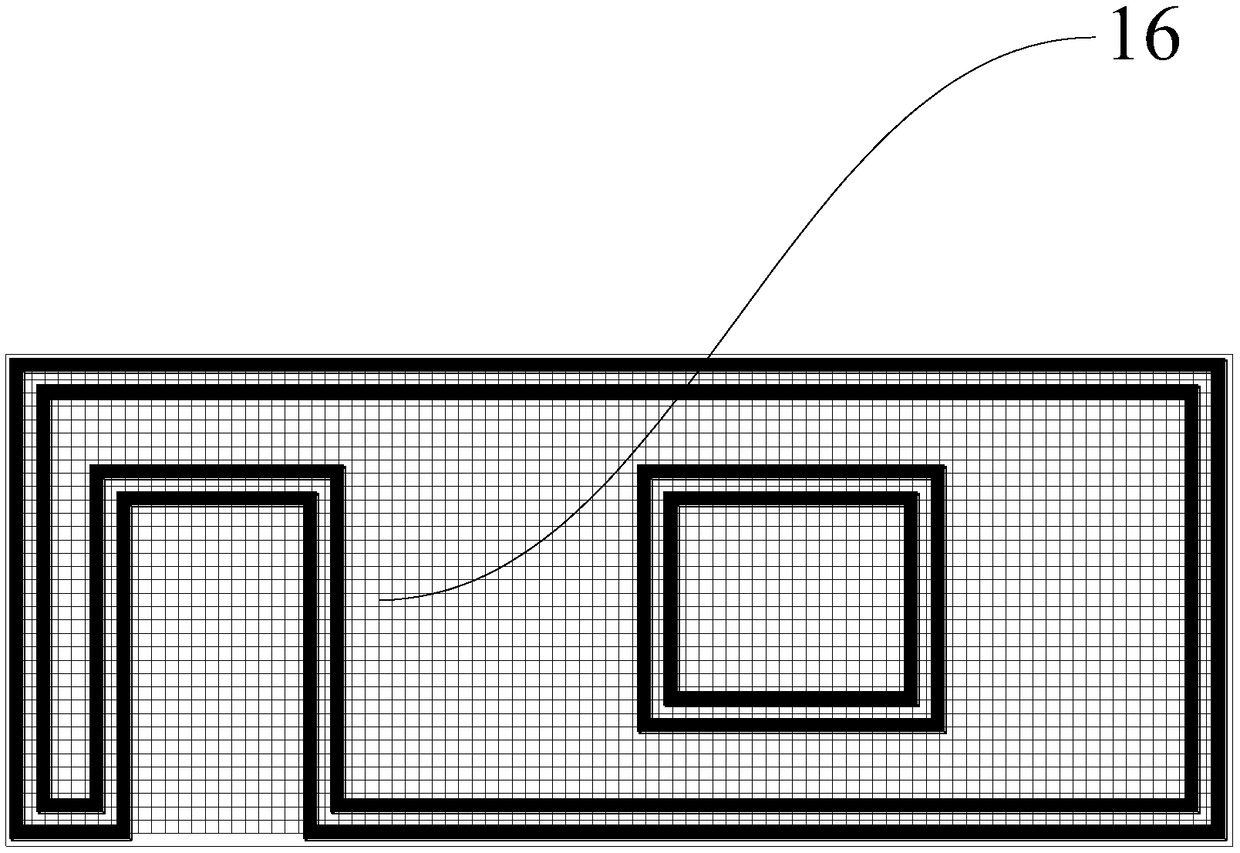

[0038] Embodiments of the present invention are as follows, with reference to figure 1 and figure 2 as well as Figure 6-8 , a rapid mold distribution device, comprising a support 12, a walking frame 11, a lifting mechanism 13, a side mold module unit 1, a module group bearing platform 15, a module control group 16, a controller and a working mold table 18, the walking frame 11 It is arranged on the support 12 and can move along the predetermined track on the support 12. The lifting mechanism 13 is fixed on the walkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com