Lifting type air floatation structure for treatment of pickling sludge

A pickling sludge, lifting technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, special treatment targets, etc., can solve the slag removal operation that cannot be stabilized by pickling sludge, unreasonable design, cost High-level problems, to achieve high-quality and stable slag removal operations, reasonable design structure, and low working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

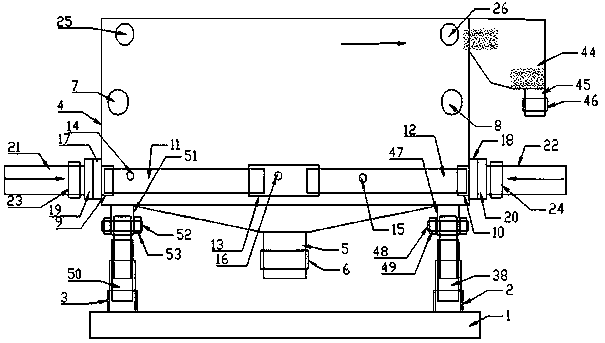

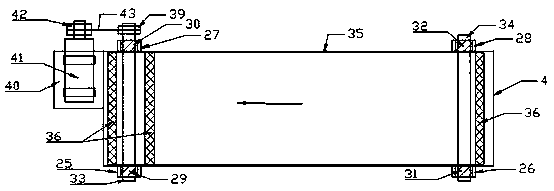

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5The lifting air flotation structure applied to pickling sludge treatment shown is composed of a lifting adjustment component, an air flotation component used in conjunction with the lifting adjustment component, and a slag scraping component used in conjunction with the air flotation component; The lifting adjustment assembly includes a base 1, a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 symmetrically arranged at both ends of the base 1, and a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 respectively. A group of first lifting cylinders 38 on the first group of cylinder positioning seats 3, a group of second lifting cylinders 50, and a group of first lifting cylinders 38 and a group of second lifting cylinders 50 used in conjunction with one group of first lifting cylinders respectively One auxiliary po...

Embodiment 2

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The lifting air flotation structure applied to pickling sludge treatment shown is composed of a lifting adjustment component, an air flotation component used in conjunction with the lifting adjustment component, and a slag scraping component used in conjunction with the air flotation component; The lifting adjustment assembly includes a base 1, a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 symmetrically arranged at both ends of the base 1, and a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 respectively. A group of first lifting cylinders 38 on the first group of cylinder positioning seats 3, a group of second lifting cylinders 50, and a group of first lifting cylinders 38 and a group of second lifting cylinders 50 used in conjunction with one group of first lifting cylinders respectively One auxiliary p...

Embodiment 3

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The lifting air flotation structure applied to pickling sludge treatment shown is composed of a lifting adjustment component, an air flotation component used in conjunction with the lifting adjustment component, and a slag scraping component used in conjunction with the air flotation component; The lifting adjustment assembly includes a base 1, a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 symmetrically arranged at both ends of the base 1, and a group of first cylinder positioning seats 2 and a group of first cylinder positioning seats 3 respectively. A group of first lifting cylinders 38 on the first group of cylinder positioning seats 3, a group of second lifting cylinders 50, and a group of first lifting cylinders 38 and a group of second lifting cylinders 50 used in conjunction with one group of first lifting cylinders respectively One auxiliary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com