Deterrent for double-base propellant, and preparation method and application of deterrent

A desensitizing agent and catalyst technology, applied in non-explosive desensitizer/passivating agent, non-explosive/non-thermal agent component, explosive, etc., can solve the problems of reducing the ballistic performance of ammunition, suspected carcinogenicity, shortening the life of ammunition, etc. , to achieve the effect of ensuring good health, good resistance to migration, and reducing migration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

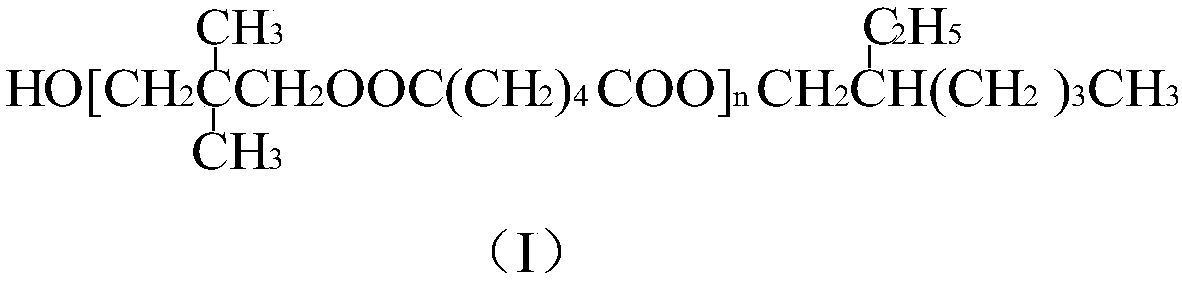

[0027] The preparation method of the double base propellant desensitizing agent provided by the present embodiment comprises the following steps:

[0028] (1) Add 250g (2.4mol) of neopentyl glycol and 320g (2.19mol) of adipic acid in sequence to a four-necked reaction flask equipped with a thermometer, agitator, condenser, oil-water separator, etc., and heat up to 100°C Melt, start stirring, then add 60g (0.46mol) isooctyl alcohol and 0.2g (0.3‰m / m) tetraisopropyl titanate to form a reaction system and raise the temperature to 140°C for 3 hours of esterification and dehydration reaction, and esterification and dehydration The water generated in the reaction process is removed after being condensed by the cooling water in the condenser tube; in this embodiment, the temperature of the cooling water is 0°C;

[0029] (2) Slowly heat up the reaction system after completing the esterification reaction in the above step (1) to 200° C. for 4 hours of reaction, then cool to 120° C. and...

Embodiment 2

[0035] The preparation method of the double base propellant desensitizing agent provided by the present embodiment comprises the following steps:

[0036] (1) Add 228.09g (2.19mol) of neopentyl glycol and 320g (2.19mol) of adipic acid in sequence to a four-necked reaction flask equipped with a thermometer, agitator, condenser, oil-water separator, etc., and heat up to 110°C Heat to melt, start stirring, then add 85.56g (0.657mol) isooctyl alcohol and 0.45g (0.7‰m / m) tetraisopropyl titanate to form a reaction system and raise the temperature to 150°C for esterification and dehydration reaction for 2 hours, and esterification The water generated in the chemical dehydration reaction process is removed after being condensed by the cooling water in the condenser; in this embodiment, the temperature of the cooling water is 15°C;

[0037] (2) Slowly heat up the reaction system after completing the esterification reaction in the above step (1) to 220°C for 3.5h, then cool to 125°C and...

Embodiment 3

[0043] The preparation method of the double base propellant desensitizing agent provided by the present embodiment comprises the following steps:

[0044](1) Add 296.52g (2.847mol) of neopentyl glycol and 320g (2.19mol) of adipic acid in sequence to a four-necked reaction flask equipped with a thermometer, agitator, condenser, oil-water separator, etc., and heat up to 105°C Heat to melt, start stirring, then add 28.52g (0.219mol) isooctyl alcohol and 0.65g (1‰m / m) tetraisopropyl titanate to form a reaction system and raise the temperature to 130°C for 2.5h of esterification and dehydration reaction, and The water generated during the esterification dehydration reaction is removed after being condensed by the cooling water in the condenser; in this embodiment, the temperature of the cooling water is 10°C;

[0045] (2) Slowly raise the temperature of the reaction system after the esterification reaction in the above step (1) to 210°C for 4.5h, then cool to 115°C and turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com