Preparation of poly alpha-olefin/ester synthesized lubricating base oil

A technology for lubricating base oil and lubricating oil, applied in the field of lubricating base oil, can solve problems such as poor effect, and achieve the effects of improving poor solubility, improving viscosity index, thermal stability, and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

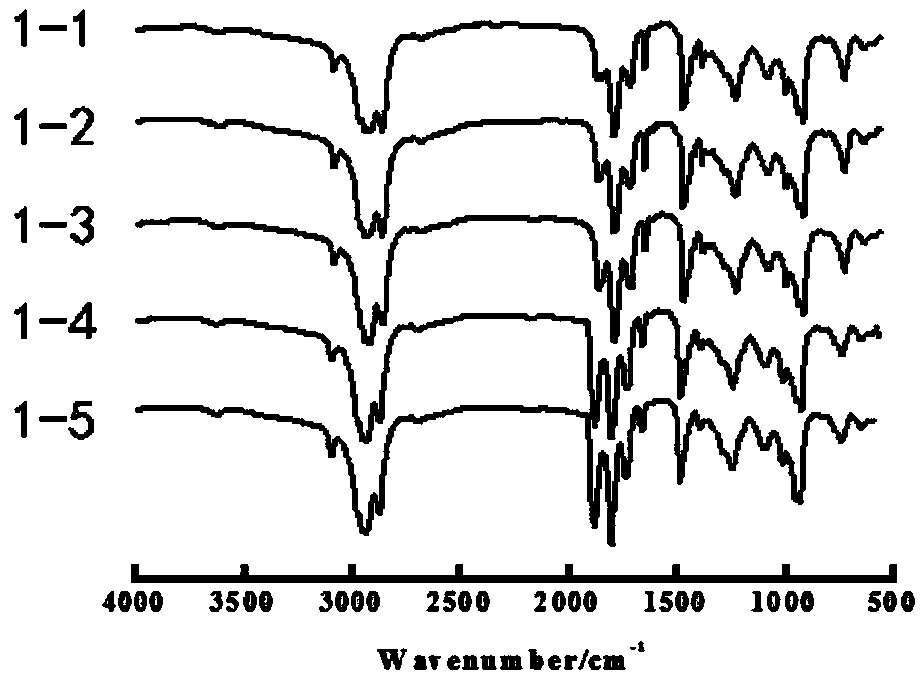

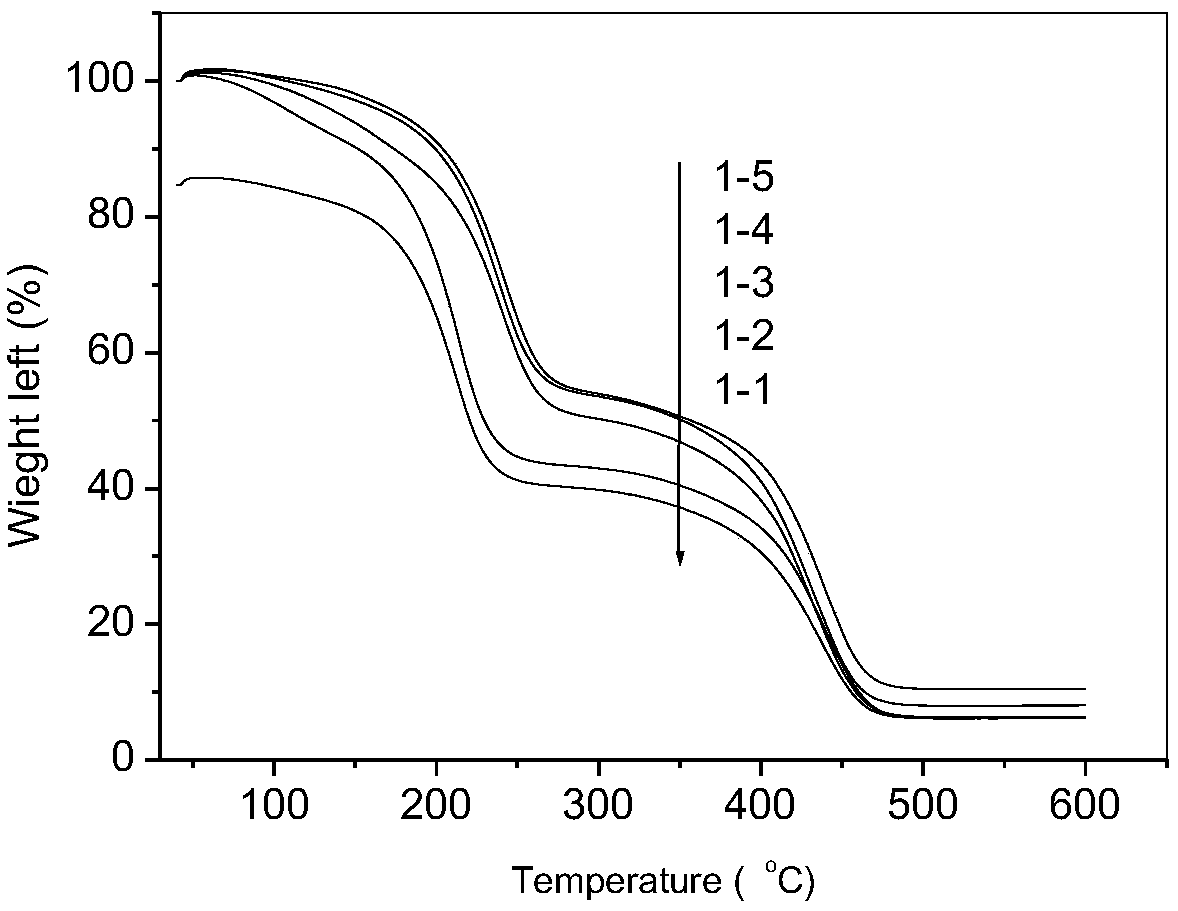

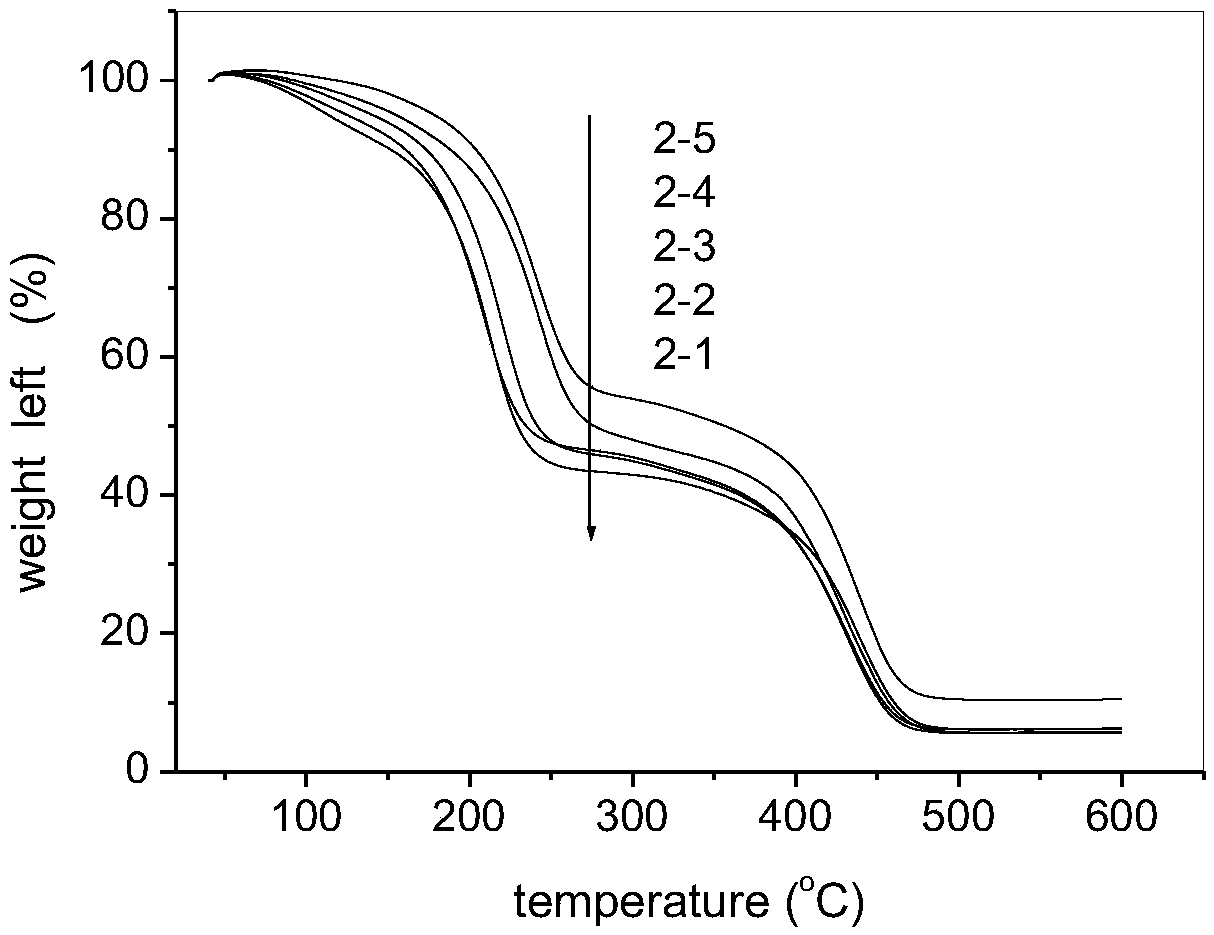

[0040] Carry out synthesis according to different mass ratios of raw material α-olefin and maleic anhydride:

[0041] Put the C14 α-olefin and maleic anhydride into the reaction kettle at a mass ratio of 100:16.7, add the solvent toluene (the mass is 2.4 to 2.64 times the mass of the α-olefin), stir continuously to dissolve the maleic anhydride completely, and then add Initiator dibenzoyl peroxide BPO (5.56% relative to the mass fraction of α-olefins), when the temperature was raised to 100 ° C for 4 hours, then directly added pentaerythritol (1.4% relative to the mass fraction of α-olefins) without separation ) and p-toluenesulfonic acid (0.5% relative to the mass fraction of α-olefin), raise the temperature to 120-150°C, react for 2-6h, wait for the theoretical amount of water to be generated, and distill off the solvent under reduced pressure at 60-100°C , continue to raise the temperature to remove p-toluenesulfonic acid to obtain the crude product. Wash the crude product...

Embodiment 2

[0044] Synthesize by adding different proportions of pentaerythritol:

[0045] Put the C14 α-olefin and maleic anhydride into the reaction kettle according to the mass ratio of 100:19.5, add an appropriate amount of solvent toluene (the mass is 2.4 times the mass of the α-olefin), and stir continuously until the maleic anhydride is completely dissolved. Agent BPO (mass fraction relative to α-olefin is 5.56%), when the temperature is raised to 100°C for 4 hours, pentaerythritol (mass fraction relative to α-olefin is 0.2%) is directly added without separation, p-toluenesulfonic acid is added (The mass fraction relative to α-olefin is 0.5%), raise the temperature to 120-150°C, react for 2-6h, wait for the theoretical amount of water to be generated, remove the solvent by distillation under reduced pressure at 60-100°C, and continue to raise the temperature to remove p-toluene Sulfonic acid, to obtain the crude product, wash with a mass fraction of 5% sodium bicarbonate solution, ...

Embodiment 3

[0048] Synthesis of C16 α-olefins instead of C14 α-olefins:

[0049] Specifically, similar to Example 1, the C16 α-olefin and maleic anhydride are put into the reaction kettle at a mass ratio of 100:18.0, an appropriate amount of solvent toluene is added, and the maleic anhydride is completely dissolved by constant stirring, and then the initiator is added over a period of Oxidize dibenzoyl BPO (5.56% relative to the mass fraction of α-olefins), heat up to 100°C for 4 hours, then directly add pentaerythritol (1.4% relative to the mass fraction of α-olefins) and p-toluene without separation Sulphonic acid (0.5% relative to the mass fraction of α-olefin), raise the temperature to 120-150°C, react for 2-6h, wait for the theoretical amount of water to be generated, remove the solvent by distillation under reduced pressure at 60-100°C, continue to heat up to remove the toluenesulfonic acid to give the crude product. Wash with 5% sodium bicarbonate solution, and finally wash with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com