Device for cutting carbon fiber cloth used in preparing outer layer of CT bed plate and use method thereof

A carbon fiber cloth and outer layer technology, which is applied in the field of carbon fiber cloth cutting equipment for the preparation of the outer layer of CT bed boards, can solve the problems of low efficiency, change of cutting shape, and defective products, etc., and achieve high cutting efficiency, smooth cutting process, Guarantee the effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

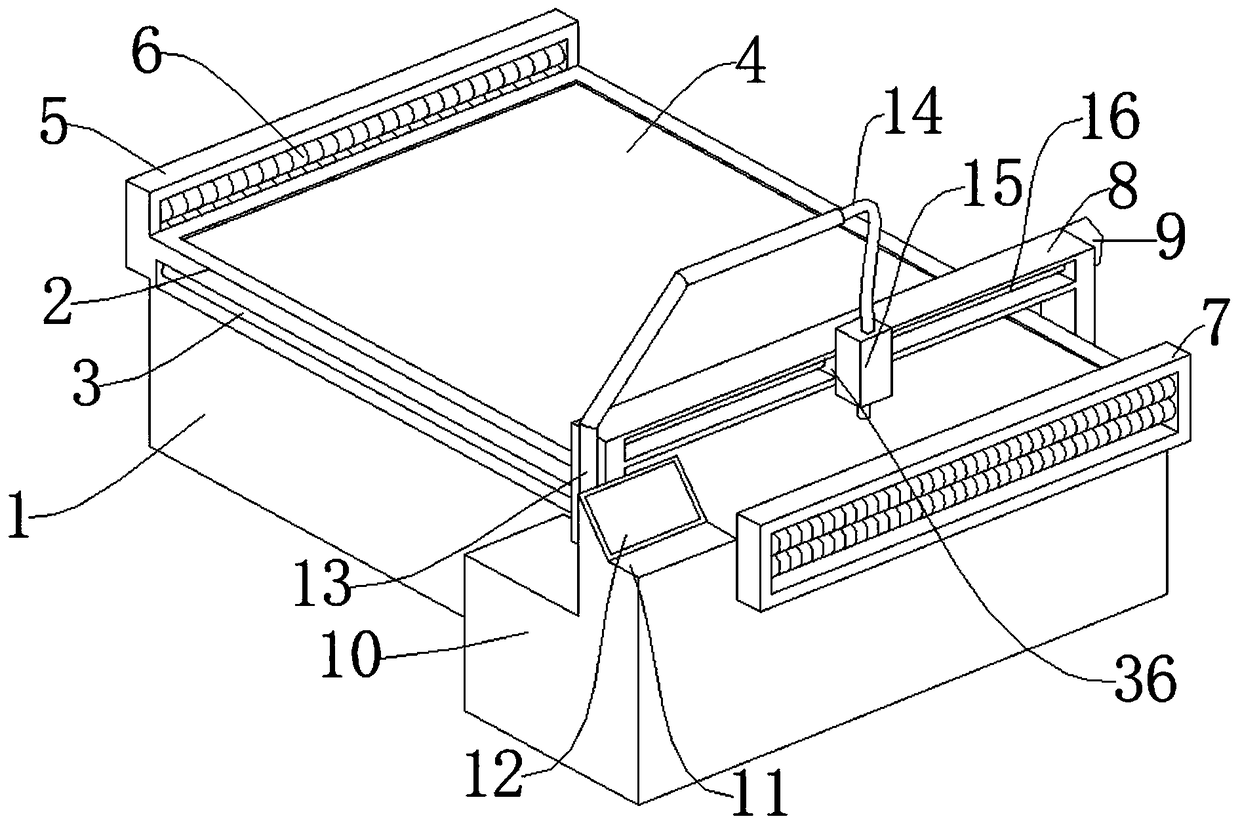

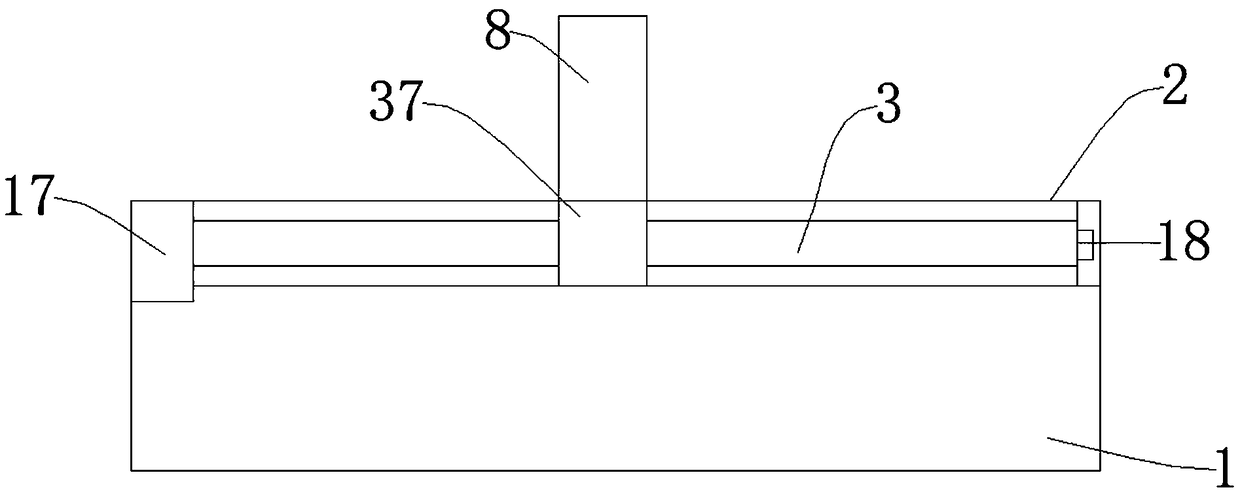

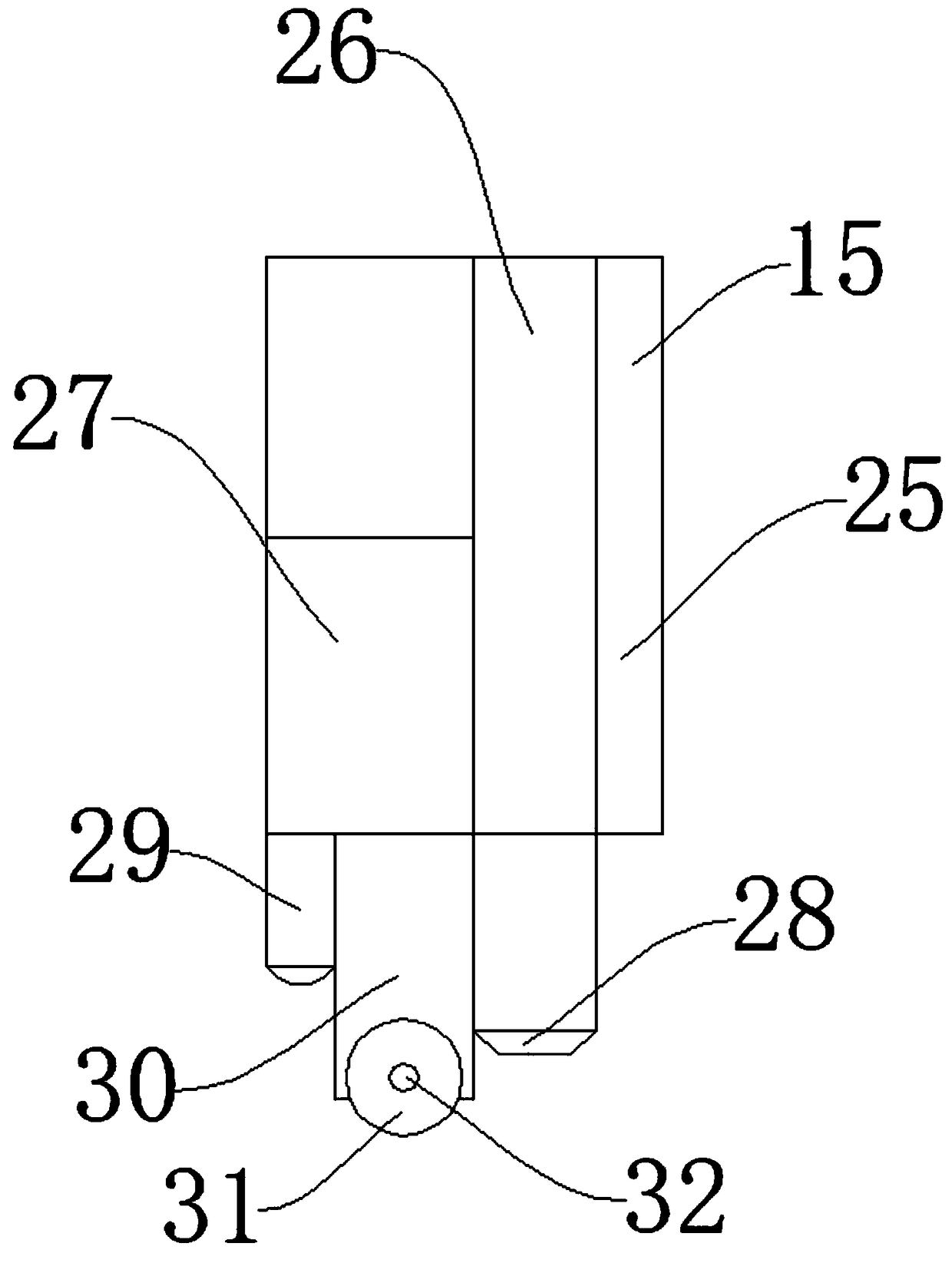

[0048] like Figure 1-Figure 9 As shown, a carbon fiber cloth cutting device for preparing the outer layer of a CT bed plate includes a device housing 1, an adjustment mechanism 6, a cutting mechanism 15, and a motor housing 10. The upper end of the device housing 1 is provided with a workbench 4, and the device housing 1 acts as a bearing, and the workbench 4 acts as a load. The workbench 4 is connected to the device shell 1 by bolts. The two sides of the workbench 4 are provided with a longitudinally moving shell 2. The longitudinally moving shell 2 plays the role of installation, and the longitudinally moving shell 2 and the device casing 1 are integrally formed, and the longitudinal movement casing 2 is provided with a longitudinal screw 3 inside, and the longitudinal screw 3 plays a transmission role. 17. The longitudinal movement motor 17 plays an energy supply role. The longitudinal movement motor 17 is connected to the device housing 1 by bolts. The front end of the lo...

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is:

[0051] A controller 35 is arranged on the upper side of the dust box 38, and the controller 35 is connected to the motor housing 10 by screws. The controller 35 plays a role of control and processing, and the connection strength is ensured by the screw connection.

[0052] The present invention also provides a method for using a carbon fiber cloth cutting device for preparing the outer layer of a CT bed slab, which is applied to the above-mentioned carbon fiber cloth cutting device for preparing the outer layer of a CT bed slab. The specific method of use is as follows:

[0053] a, control the controller 35 by the keyboard 11 and the display screen 12, the controller 35 controls the device to start, passes the carbon fiber cloth through the rear feed frame 5 and the front feed frame 7, and transmits the graphics that need to be cut into the controller 35, The device starts up.

[0054] b. The gear motor 23 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com