Wire with light guide function

A technology of optical function and wire, applied in the direction of conductors, insulated conductors, power cables, etc., can solve the problems of error prone, labor-intensive, time-consuming, and poor adhesion of number tube writing, so as to improve accuracy and reduce time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

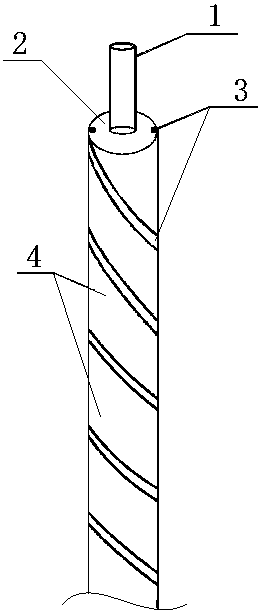

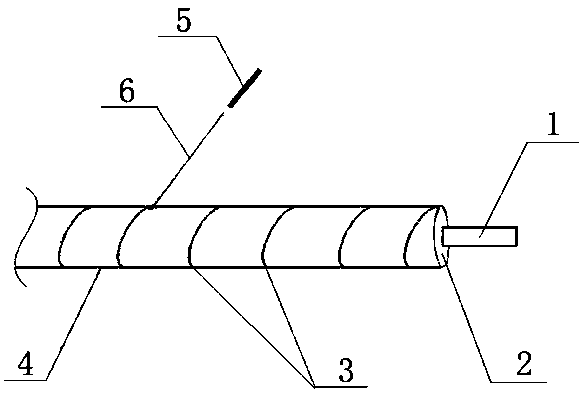

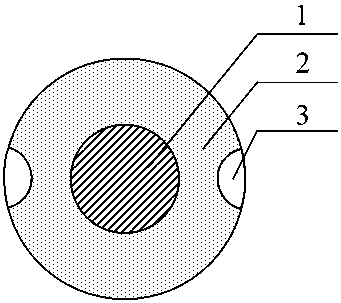

[0022] In order to make the object, technical scheme and advantages of the present invention clearer, the following in conjunction with the attached figure 1 - attached image 3 and specific examples to clearly and completely describe the invention.

[0023] Such as Figure 1-Figure 3 As shown, this embodiment relates to a wire with a light guiding function, which includes a conductor wire 1 and an insulating outer layer 2 wrapped outside the conductor wire 1, and a spiral groove is opened on the insulating outer layer 2. The optical fiber 3 is embedded in the spiral groove, and the surface of the optical fiber 3 is wrapped with a transparent adhesive layer 4 .

[0024] Further, the optical fiber 3 is polymethyl methacrylate, which is non-toxic and environmentally friendly, and has good chemical stability and weather resistance.

[0025] Further, the transparent adhesive layer 4 is made of transparent PRTV anti-corrosion material.

[0026] Further, there is more than one s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com