Intermediate sound frequency and high sound frequency integrated loudspeaker

A loudspeaker, integrated technology, applied in the field of loudspeakers, can solve the problems of long travel, design, high-frequency part can not reach 20,000 Hz, etc., and achieve the effect of high diaphragm strength and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

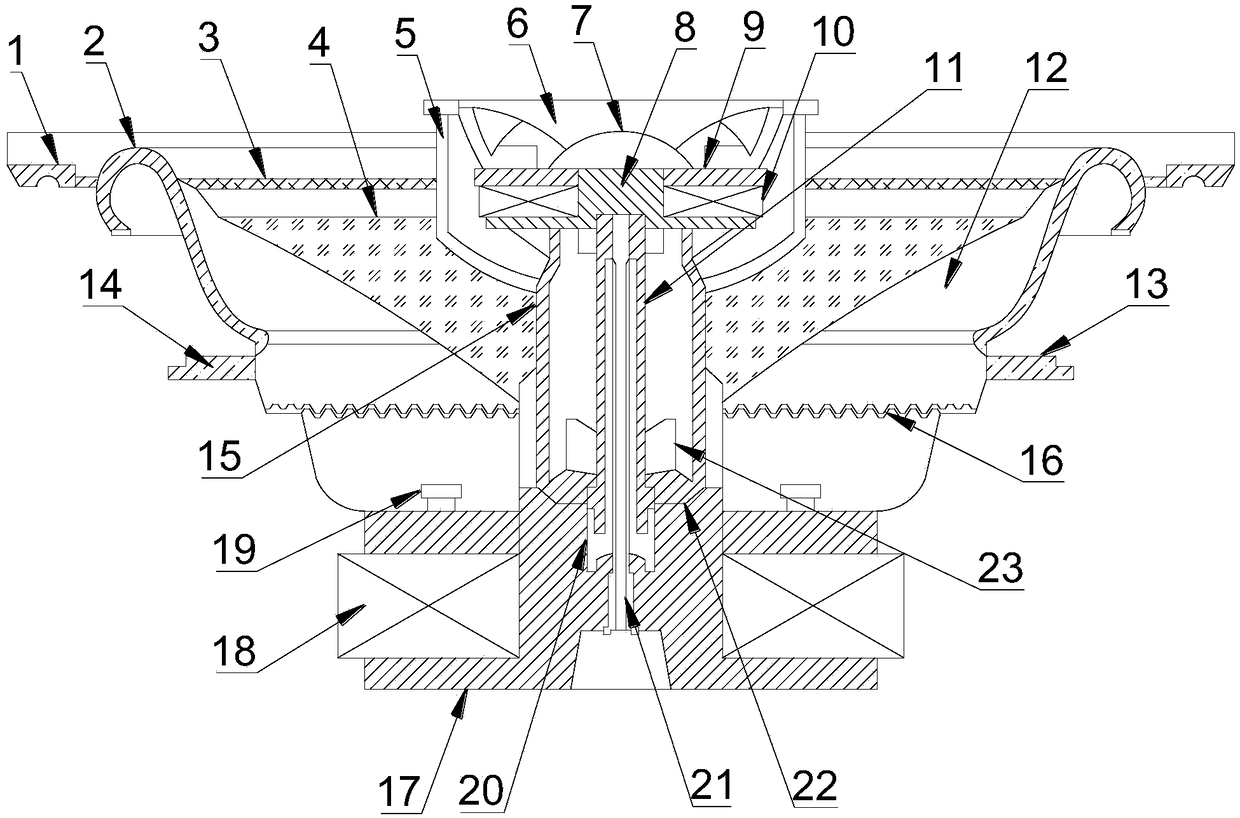

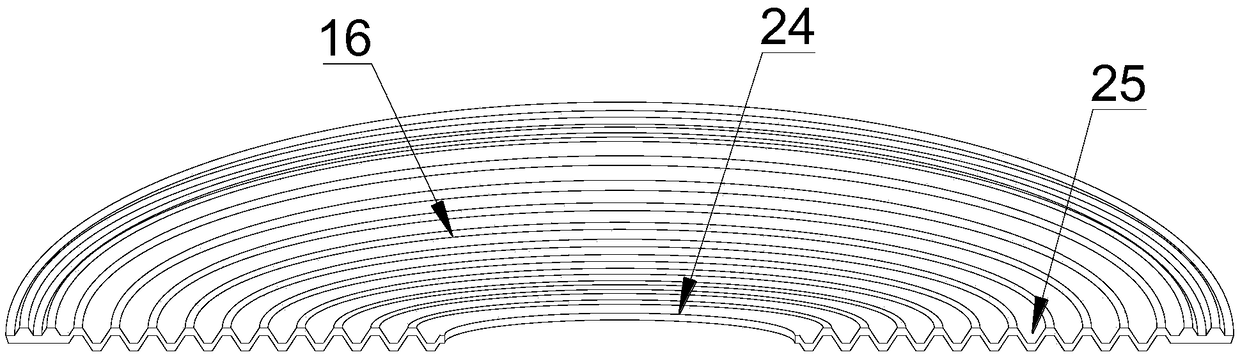

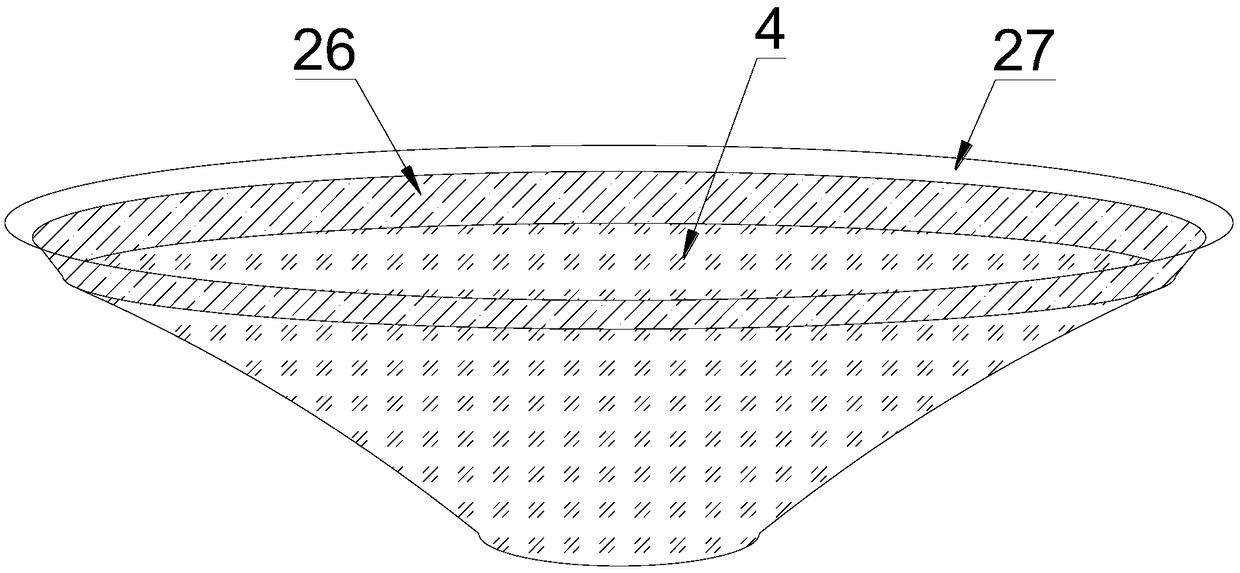

[0025] see Figure 1 ~ Figure 3 , in Embodiment 1 of the present invention, a mid-to-high-frequency integrated speaker includes a speaker frame 2, a vibrating membrane 4, a voice coil housing 5, a magnetic guide column 8, a damper 16, and a speaker chassis 17, and the speaker frame 2. The outer edge of the upper end is connected to the edge retaining ring 1. The speaker pot frame 2 is a horn-shaped open die-casting made of aluminum. The outer edge of the upper end of the speaker pot frame 2 is provided with a bending part. The fixing ring 13 is provided with several screw holes 14, and the screw holes 14 are equally spaced along the fixing ring 13. Preferably, in this embodiment, the number of screw holes 14 is three, which is convenient for assembling the speaker frame 2 by screws. speakers for assembly.

[0026] The bottom of the speaker basin frame 2 is connected to the speaker chassis 17 by screws 19, the speaker chassis 17 is provided with a magnet 18, the magnet 18 is e...

Embodiment 2

[0039] see Figure 1 ~ Figure 3 , in Embodiment 1 of the present invention, a mid-to-high-frequency integrated speaker includes a speaker frame 2, a vibrating membrane 4, a voice coil housing 5, a magnetic guide column 8, a damper 16, and a speaker chassis 17, and the speaker frame 2. The outer edge of the upper end is connected to the edge retaining ring 1. The loudspeaker frame 2 is a trumpet-shaped open die-casting made of magnesium. The outer edge of the upper end of the speaker frame 2 is provided with a bending part. The outer edge of the speaker frame 2 is connected to the fixing ring 13. The fixing ring 13 is provided with a number of screw holes 14, and the screw holes 14 are equally spaced along the fixing ring 13. Preferably, in this embodiment, the number of screw holes 14 is four, which is convenient for assembling the speaker frame 2 by screws. speakers for assembly.

[0040] The bottom of the speaker basin frame 2 is connected to the speaker chassis 17 by screw...

Embodiment 3

[0053] see Figure 1 ~ Figure 3 , in Embodiment 1 of the present invention, a mid-to-high-frequency integrated speaker includes a speaker frame 2, a vibrating membrane 4, a voice coil housing 5, a magnetic guide column 8, a damper 16, and a speaker chassis 17, and the speaker frame 2. The outer edge of the upper end is connected to the edge retaining ring 1. The loudspeaker basin frame 2 is a trumpet-shaped open die-casting made of zinc. The outer edge of the upper end of the speaker basin frame 2 is provided with a bending part. The fixing ring 13 is provided with a number of screw holes 14, and the screw holes 14 are equally spaced along the fixing ring 13. Preferably, in this embodiment, the number of screw holes 14 is five, which is convenient for assembling the speaker frame 2 by screws. speakers for assembly.

[0054] The bottom of the speaker basin frame 2 is connected to the speaker chassis 17 by screws 19, the speaker chassis 17 is provided with a magnet 18, the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com