Meat sausage processing line

A processing line and meat sausage technology, which is applied in the direction of meat processing equipment, processed meat, mixed meat equipment, etc., can solve the problem of low work efficiency, high labor costs, and the inability to accurately determine whether the meat is mixed with the required size of diced meat Or meat paste and other problems, to achieve the effect of convenient material extraction, convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

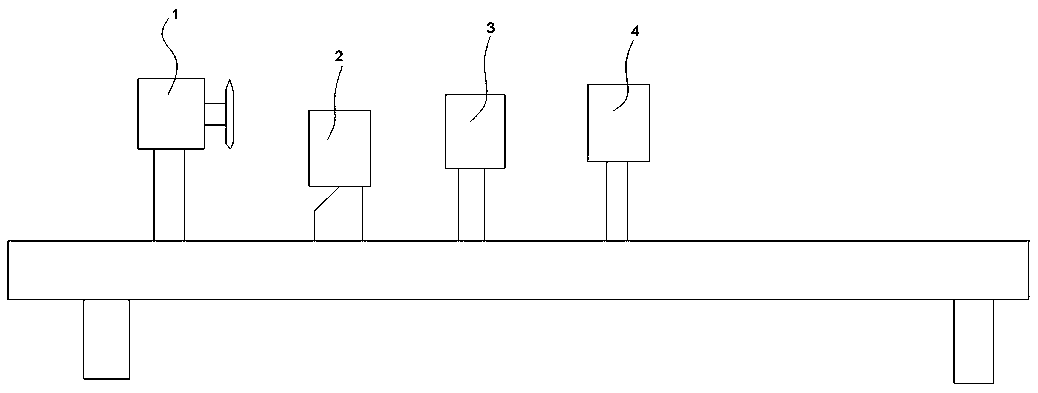

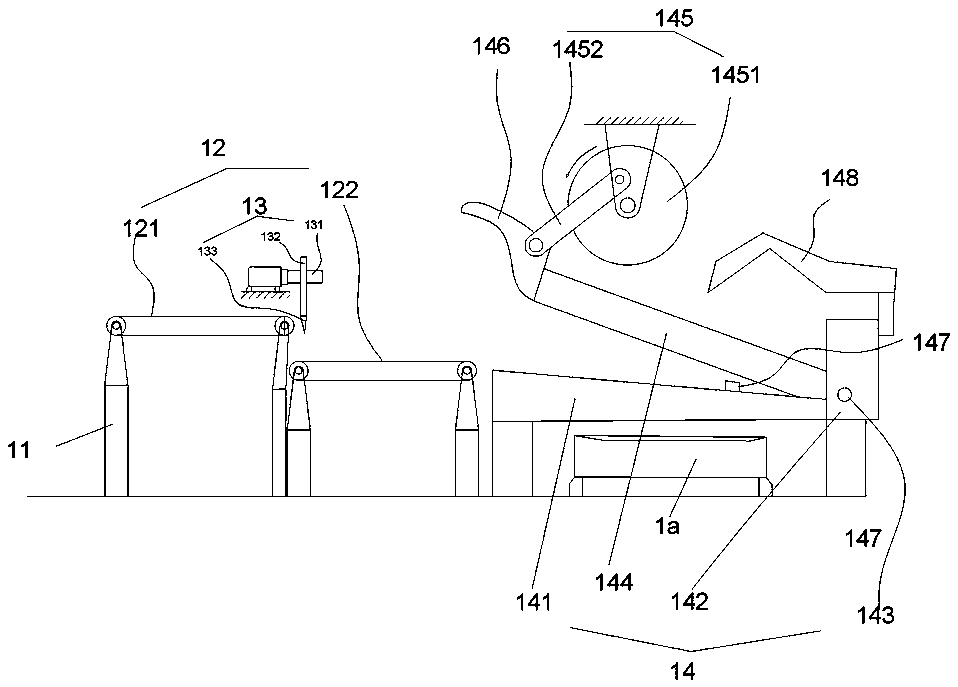

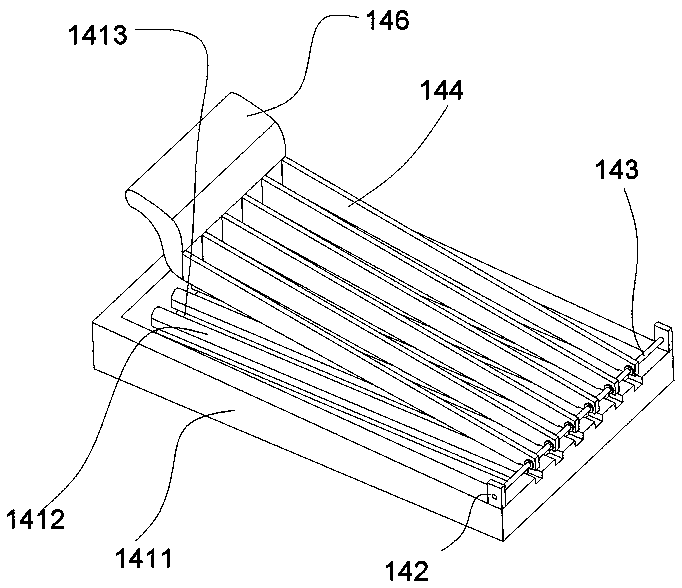

[0057] Such as figure 1 As shown, a meat sausage processing line includes a meat cutting device 1, a stirring device 2, a sausage enema device 3, and a cooking device 4 arranged in sequence, all of which are installed on the processing line support, and the processing line support can be made of profile parts such as square steel Welded; such as Figure 2-4 As shown, the meat cutting device includes a meat cutting machine frame 11, a conveyor belt 12 arranged on the meat cutting machine frame 11, a rotary cutter 13 for slicing large pieces of meat, and a rotary cutter 13 for The dicing knife 14 that sliced meat is cut into diced meat, and the meat cutter frame 11 can be an assembly of profile parts such as square steel, which is not specifically limited here; the conveyor belt 12 includes an upper conveyor belt 121, located The lower co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com