Device and method for fully automatically filtering sodium vanadate crystals

A sodium vanadate, fully automatic technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of difficult continuous operation and filtration of filter cloth gaps, achieve good application prospects, improve filtration efficiency, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

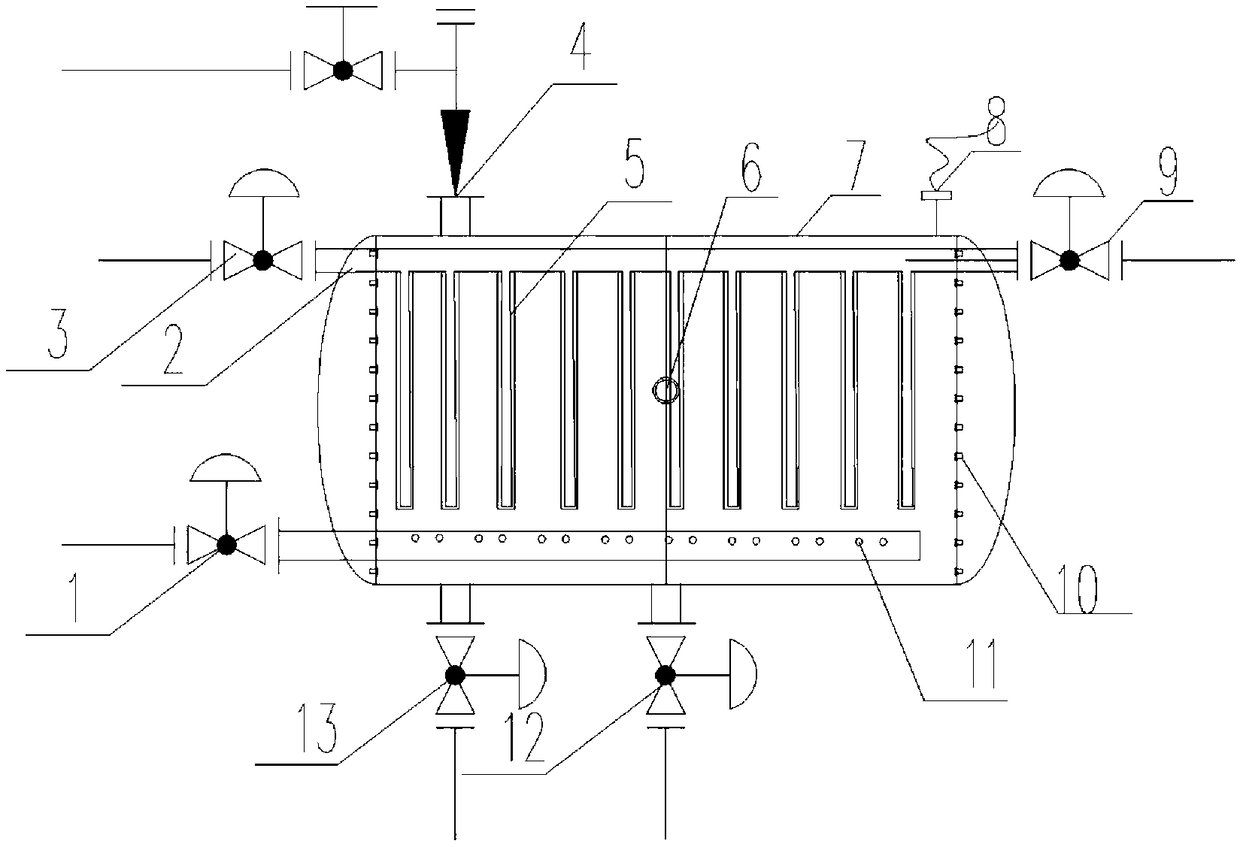

[0038] The present embodiment provides a kind of device of fully automatic filtration sodium vanadate crystal, described device comprises still body and shell 7, and described still body is provided with filter plate 5, is distributed with filter cloth between described filter plate 5, so The kettle body is respectively provided with a feed inlet 1, a liquid outlet 9, a discharge port 12 at the bottom of the kettle body, and a steam blowback port 3 at the top of the kettle body.

[0039] Further, the device also includes an air-dried gas inlet 4 on the top of the kettle body and a sewage outlet 13 on the bottom of the kettle body, as well as an observation port 6, a pressure sensing device 8 and a plate repair flange 10 on the kettle body.

[0040] Further, the kettle body is provided with a liquid outlet pipe 2 connected to the liquid outlet, and the liquid outlet pipe 2 is connected to the steam blowback port 3 . A feed pipe is provided in the kettle body, and a filtrate inl...

Embodiment 2

[0042] The present embodiment provides a kind of method for fully automatic filtration sodium vanadate crystal, utilizes the device that provides among the embodiment 1 to carry out, described method is: the mixed slurry obtained after sodium vanadate crystallization is imported from feed inlet 1, The filtrate is uniformly distributed through the cloth inlet 11 on the feed pipe and then enters the filter plate 5 for filtration. At this time, except for the feed inlet 1 and the liquid outlet 9, all other inlets and outlets connected to the outside world are closed. After the filtration is completed, the sodium vanadate crystals remain on the filter cloth of the filter plate 5, and the liquid is discharged from the liquid outlet 9 through the liquid outlet pipe 2. During the filtration process, the content of crystals in the device is determined through the observation port 6 and the pressure sensing device 8. When the crystal content is constant, the feed port 1 and the liquid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com