Degumming machine for semiconductor processing

A semiconductor and glue machine technology, applied in the direction of spraying devices, etc., can solve the problems of flying around, affecting production efficiency, difficult to recycle, etc., achieve large-scale glue removal and collection of dry glue, prevent dry glue from flying, and facilitate collection of dry glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

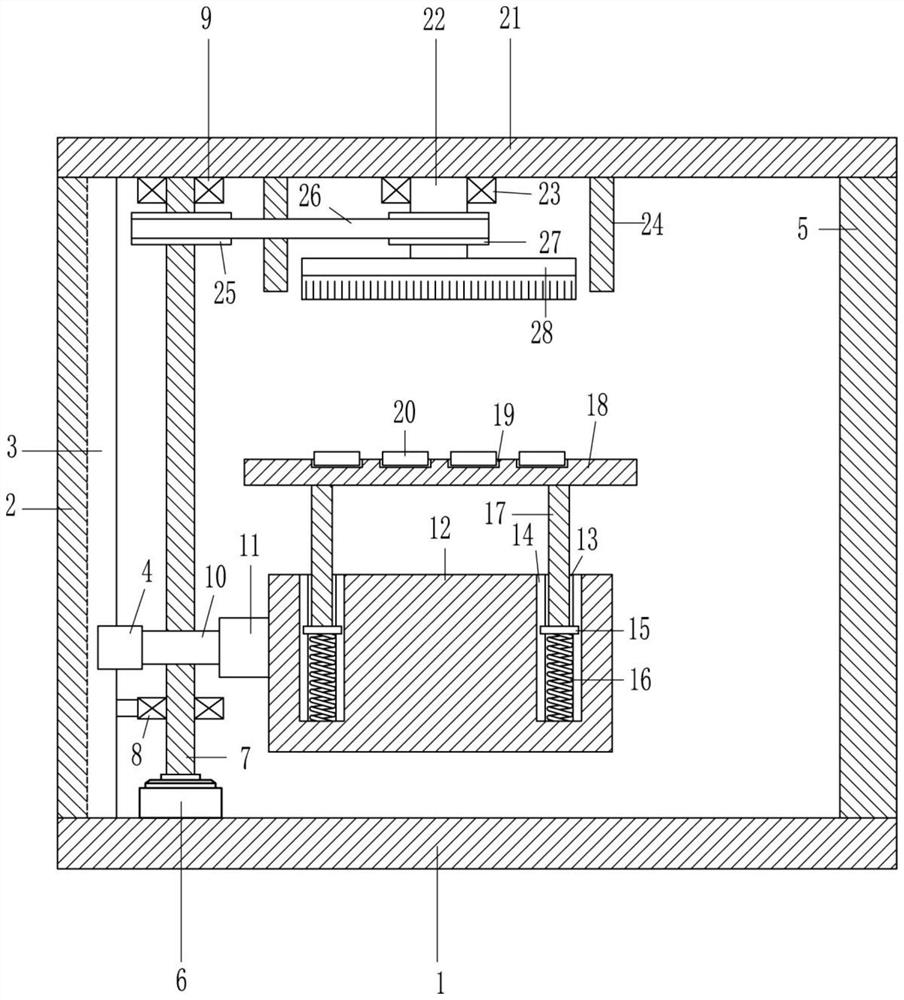

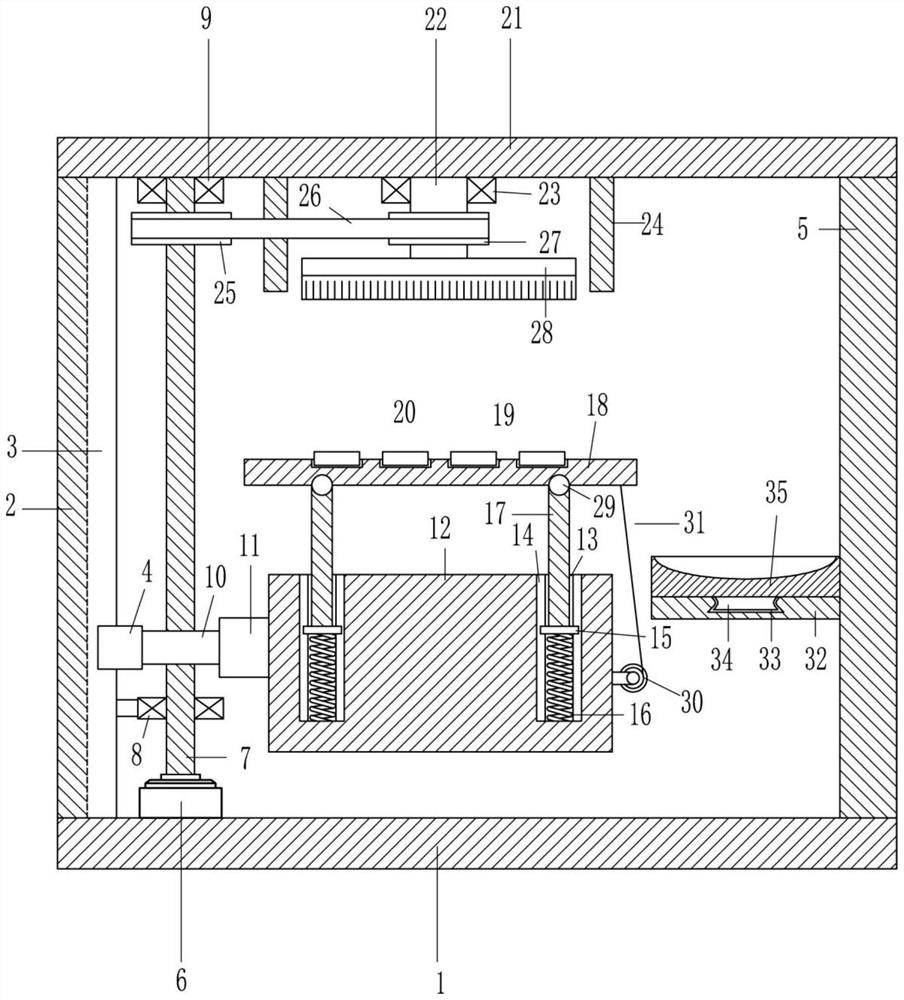

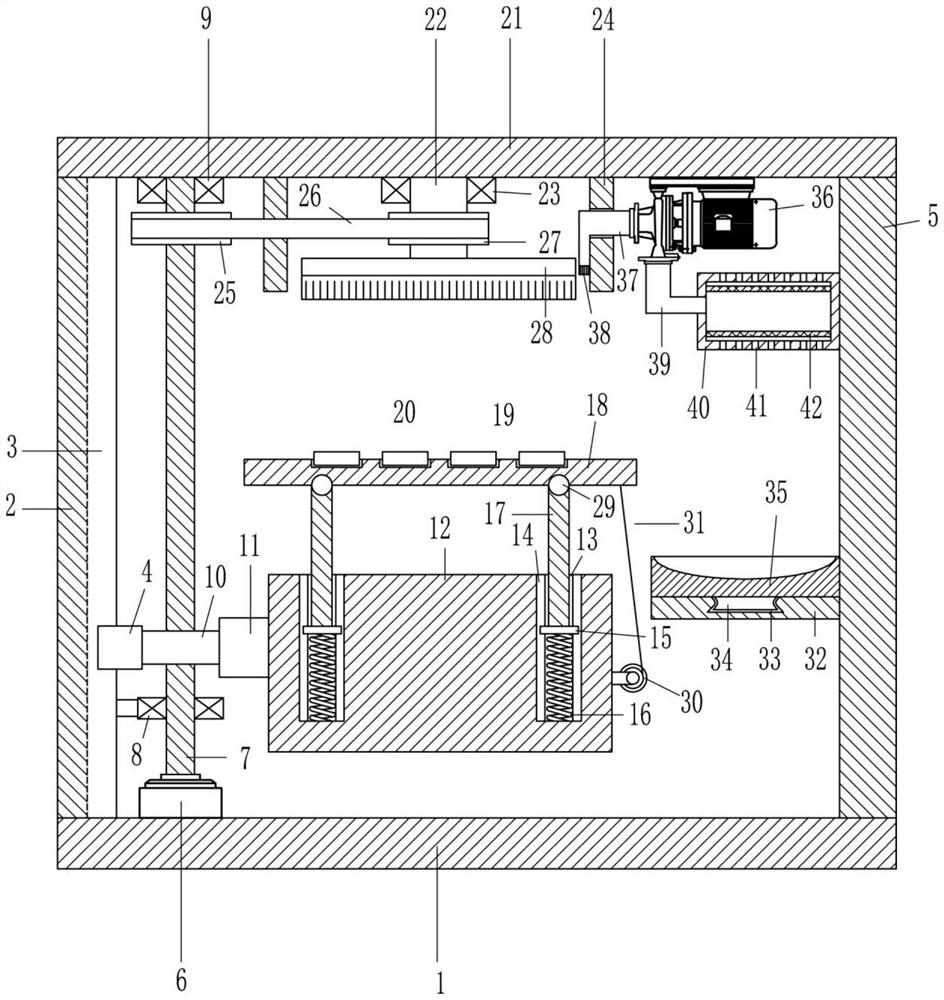

[0022] A semiconductor processing glue remover, such as Figure 1-6 As shown, it includes a mounting plate 1, a first bracket 2, a first slider 4, a second bracket 5, a motor 6, a screw 7, a first bearing seat 8, a second bearing seat 9, a nut 10, a connecting block 11, Telescopic block 12, second slide block 15, elastic member 16, telescopic rod 17, place plate 18, cover plate 21, rotating shaft 22, the 3rd bearing block 23, push bar 24, first pulley 25, flat belt 26, the second The belt pulley 27 and the glue removal brush 28; the first support 2 and the second support 5 are fixed on the top surface of the installation plate 1 in turn, and the first support 2 is provided with a first chute 3; the motor 6 is fixed on the top of the installation plate 1 On the surface, the first bearing seat 8 is affixed to the side of the first bracket 2; the cover plate 21 is affixed to the top of the first bracket 2 and the second bracket 5; the second bearing seat 9 is affixed to the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com