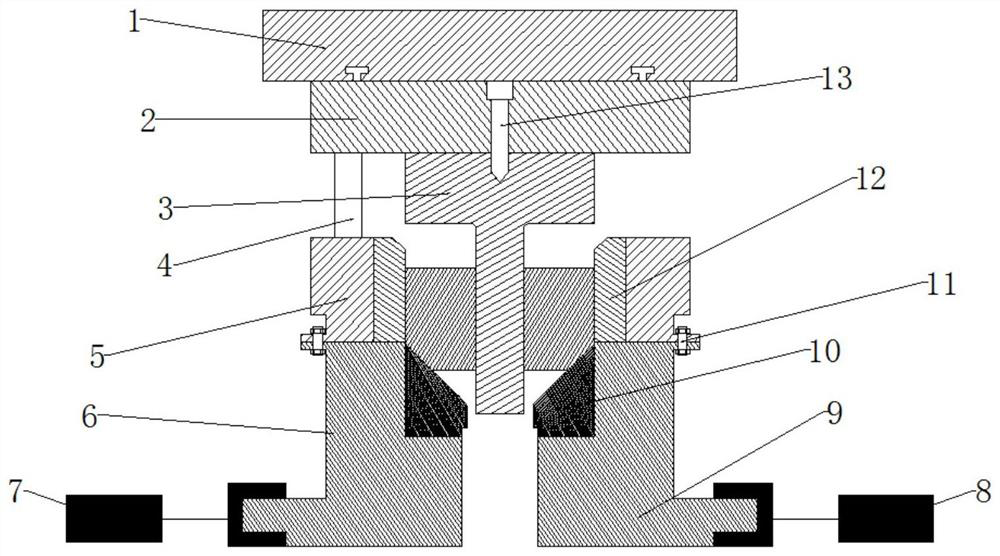

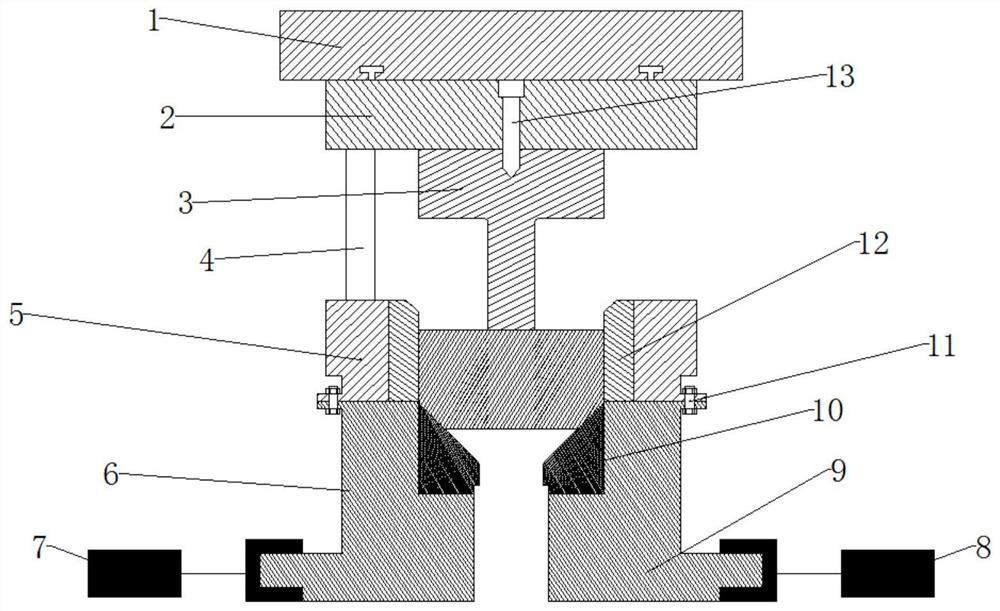

A large length-to-diameter ratio hollow thin-walled shaft extrusion preparation device and method

A hollow thin-walled, large aspect ratio technology, used in metal extrusion, metal extrusion dies, metal containers to be extruded, etc., can solve problems such as breaking, shaft blank deformation, and reducing the utilization rate of forging raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] The extrusion billet is 304 stainless steel bar, the specification is Ф200mm*150mm, the outer diameter of the hollow thin-walled shaft with a large aspect ratio is 100mm, the inner diameter is 85mm, and the length is not less than 1500mm. Its implementation scheme is as follows:

[0055] (1) Install the extrusion rod with a diameter of 85mm and the upper backing plate on the upper mold base of the extrusion machine in sequence;

[0056] (2) After splicing and assembling the left half die and the right half die to form a die, start the left hydraulic cylinder and the right hydraulic cylinder;

[0057] (3) putting the extruding outlet diameter into the die for 100mm extruding die core;

[0058] (4) Heat the extrusion barrel to 200°C to 300°C, place it on the die, and the backing plate on the extruder goes down to ensure that the centering and positioning of the extrusion rod is completed, and then tighten the fastening bolts;

[0059] (5) Spray high-temperature lubrican...

Embodiment 2

[0066] The extrusion blank is TC4 titanium alloy bar, the specification is Ф150mm*200mm, and the center is pre-cut with a diameter of 60mm. The outer diameter of the hollow thin-walled shaft with a large aspect ratio is 80mm, the inner diameter is 60mm, and the length is not less than 1000mm. . Its implementation scheme is as follows:

[0067] (1) Install the extrusion rod with a diameter of 60mm and the upper backing plate on the upper mold base of the extrusion machine in sequence;

[0068] (2) After splicing and assembling the left half die and the right half die to form a die, start the left hydraulic cylinder and the right hydraulic cylinder;

[0069] (3) putting the extrusion die core with an extrusion outlet diameter of 80mm into the die;

[0070] (4) Heat the extrusion barrel to 200°C to 300°C, place it on the die, and the backing plate on the extruder goes down to ensure that the centering and positioning of the extrusion rod is completed, and then tighten the faste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com