An automatic grinding and polishing system for titanium alloy ring castings

A technology for ring castings and titanium alloys, applied in grinding/polishing equipment, grinding automatic control devices, workpiece feed movement control, etc., can solve the problem of difficult clamping of machining centers, differences in theoretical values, complex surface contours, etc. problems, to achieve the effects of improved tool life, stable processing technology, and high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

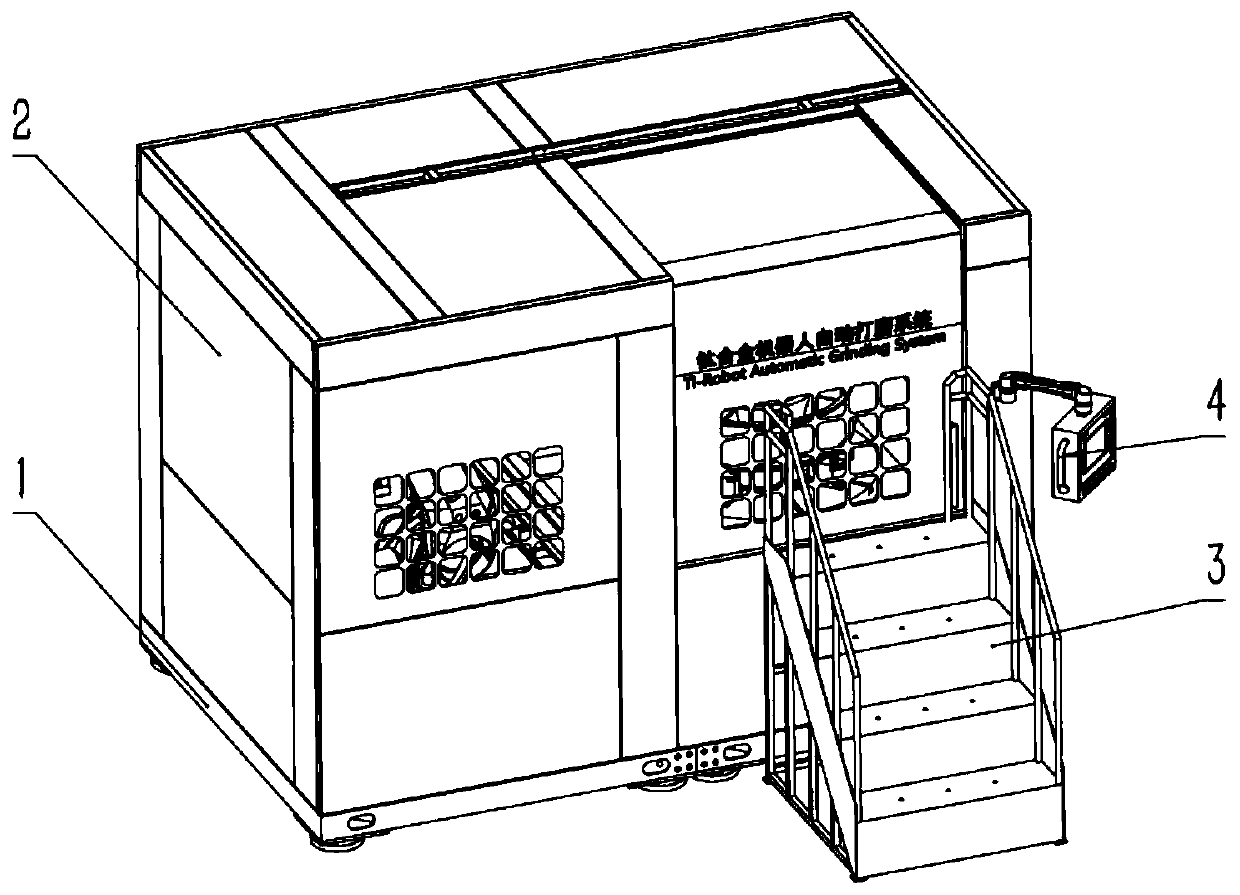

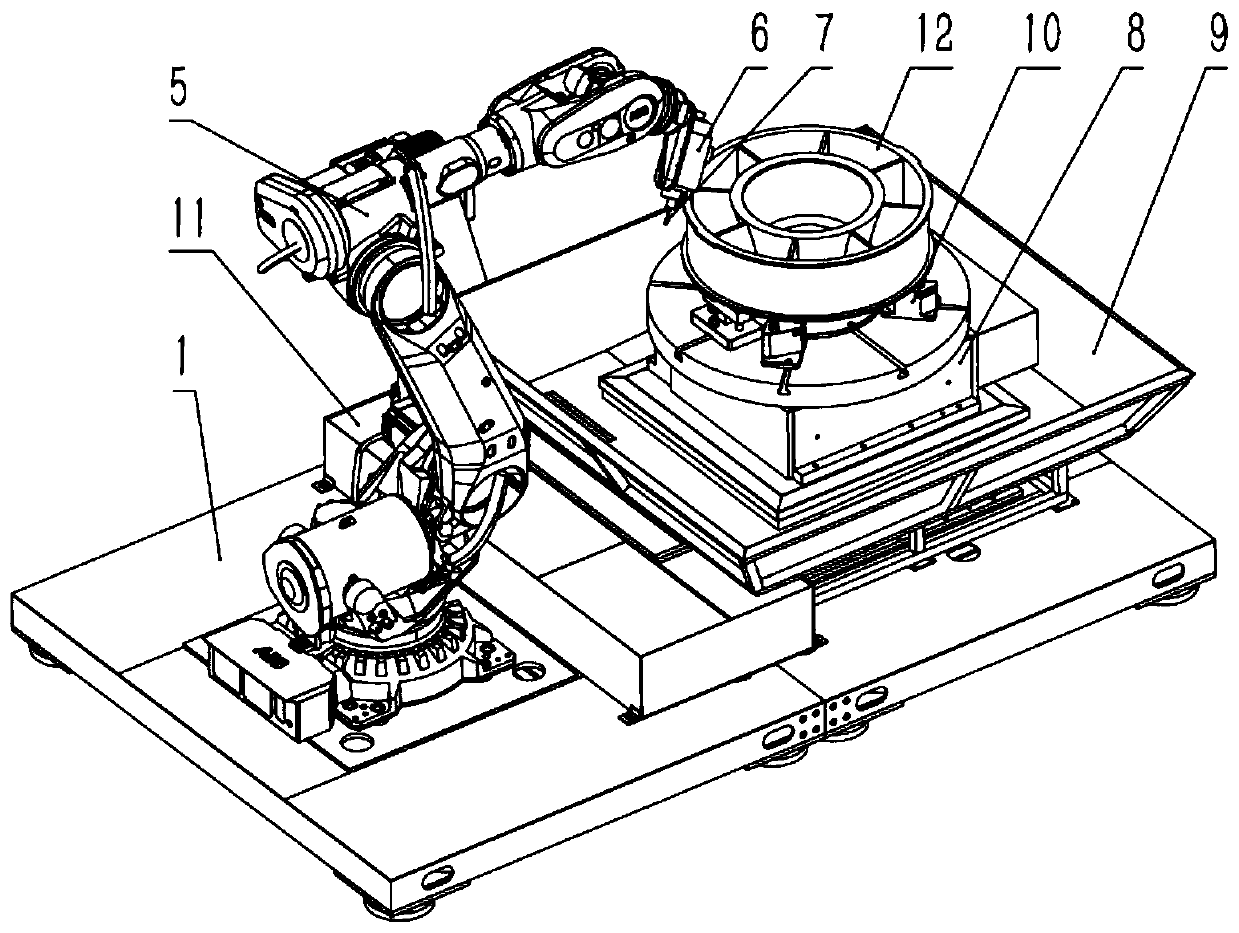

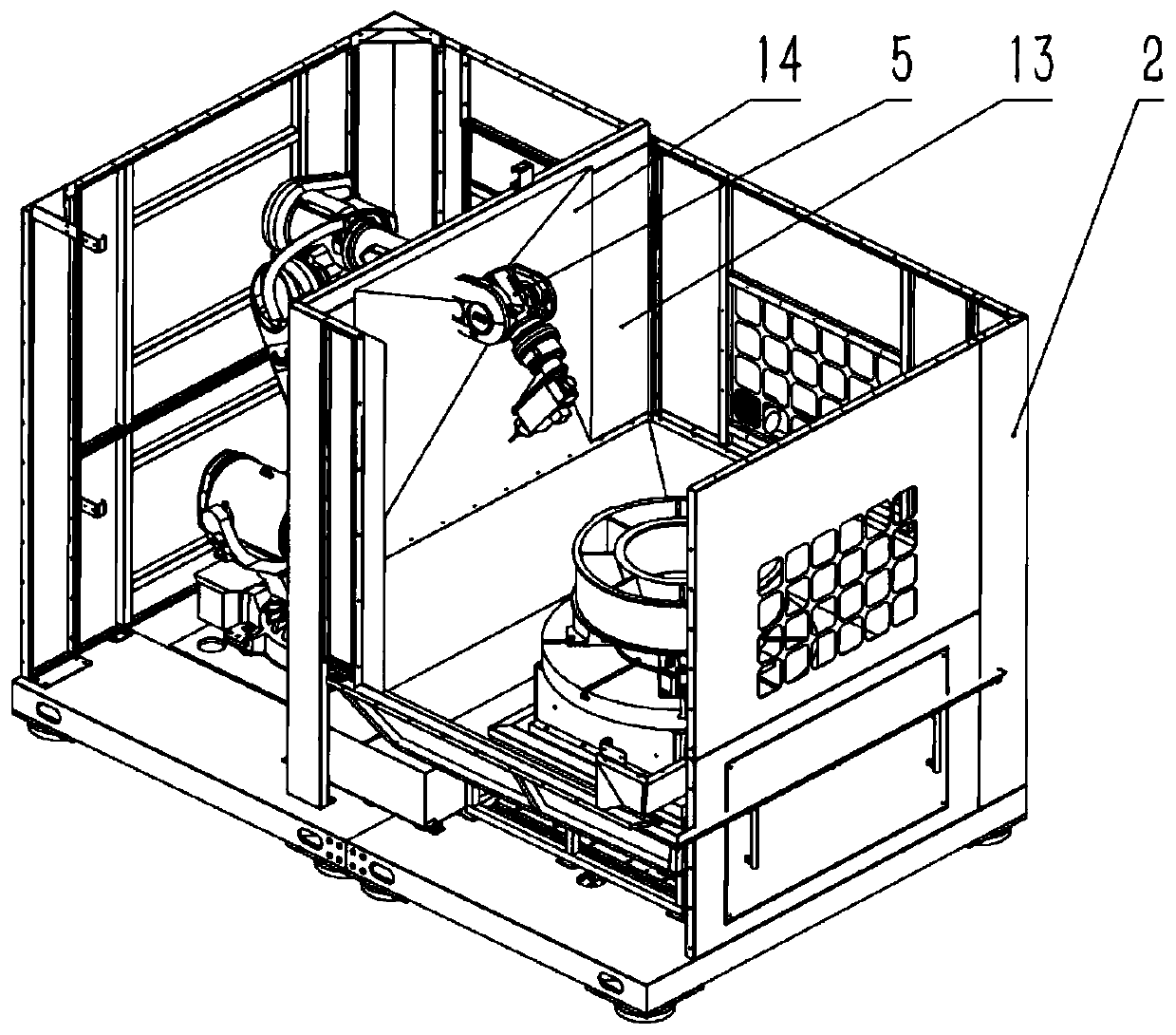

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034]In the figure, 1-base, 2-cover, 3-step, 4-display screen, 5-robot, 6-electric spindle, 7-tool, 8-fixture, 9-water tank, 10-coolant mounting frame, 11- Cooling chip conveyor, 12-titanium alloy ring casting, 13-cover partition, 14-robot jacket, 15-force control sensor, 16-laser ranging sensor, 17-sensor mounting frame, 18-coolant pipe, 19- Electric spindle mounting flange, 20-rotary table, 21-three-jaw chuck, 22-A floating V-shaped block assembly, 23-pin assembly, 24-three-jaw chuck flange, 25-pin seat, 26-outside Pin, 27-inner pin, 28-upper cover, 29 lower cover, 30-V block, 31-guide column, 32-flange copper sleeve, 33-spring, 34-limit block, 35-V block seat, 36-flat key, 37-B floating V-shaped block assembly, 38-B type rotary file, 39-C type rotary file, 40-round hole, 41-warp, 42-weft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com