Pneumatic-electric braking system and Pneumatic-electric conversion and control method of freight train

A braking system, air-electric technology, applied in the direction of brakes, brake components, brake transmission devices, etc., can solve the problems of brake control restrictions, low truck capacity, high maintenance and use costs, etc., to ensure compatibility , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A control method based on aerodynamic power generation of freight trains mainly includes the following steps:

[0024] 1) The main components of the pneumatic power generation device

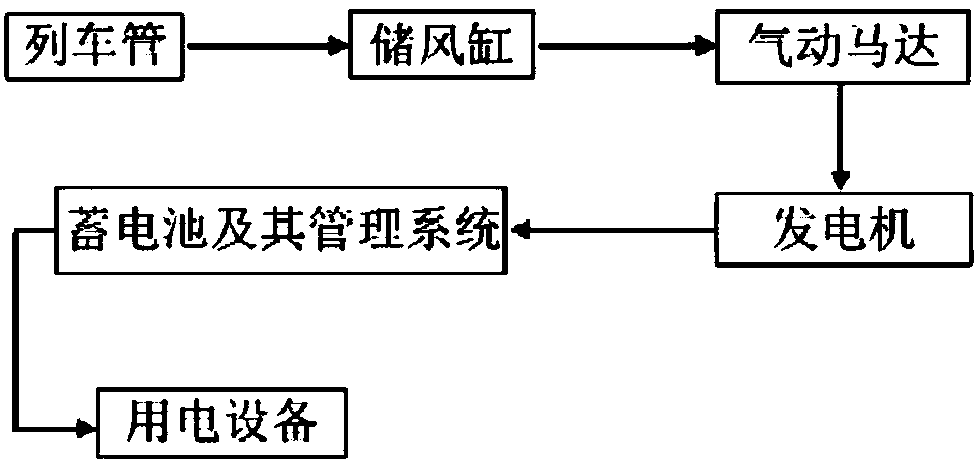

[0025] refer to figure 1 , The pneumatic power generation device mainly includes: train tube, air storage cylinder, air motor, generator, battery and its battery management system. Among them, the air storage cylinder receives the pressure air of the train pipeline through the one-way air circuit; the air motor is connected to the pressure air pressure air storage cylinder, receives the air pressure and converts it into mechanical power output; the power is input into the generator through the coupling for power generation ;Finally, after passing through the battery management system, it is input into the battery to convert the air pressure into electric energy and supply power for the vehicle control equipment. In the present invention, the generator may be a small generator.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com