Efficient oil-water phase separation device

A high-efficiency oil and water technology, applied in the direction of grease/oily substance/float removal device, liquid separation, separation method, etc., can solve the problem of low separation efficiency, avoid liquid flow turbulence, improve oil-water separation effect and separation Efficiency, the effect of slowing down the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

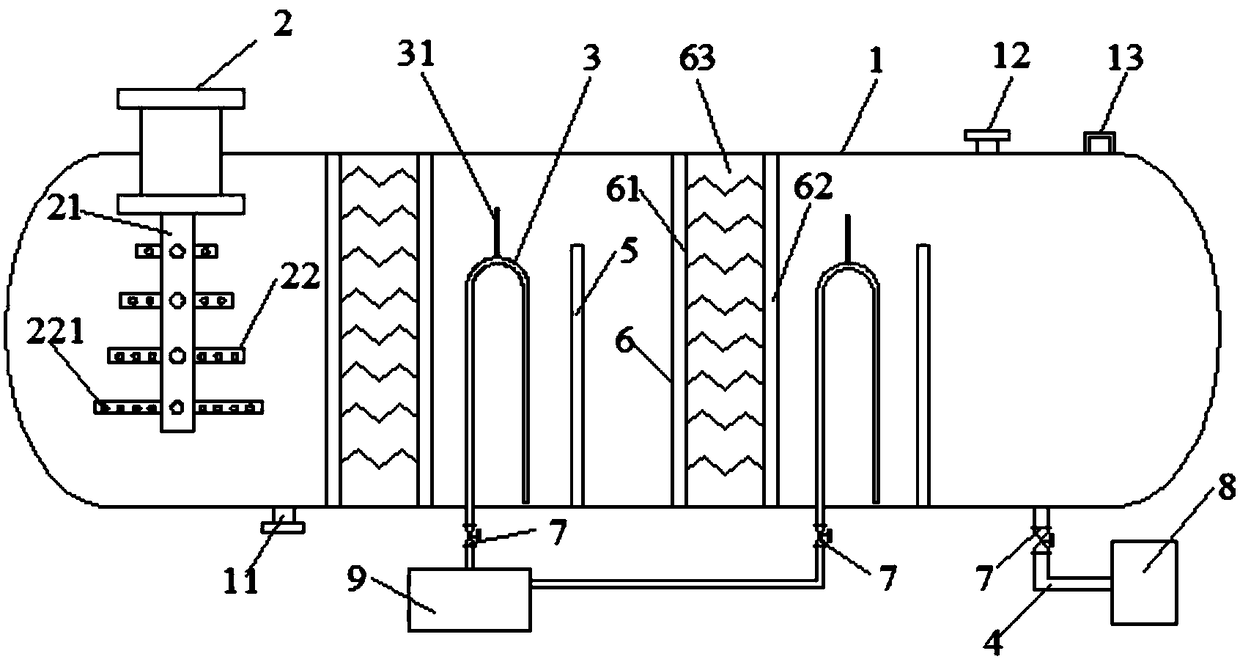

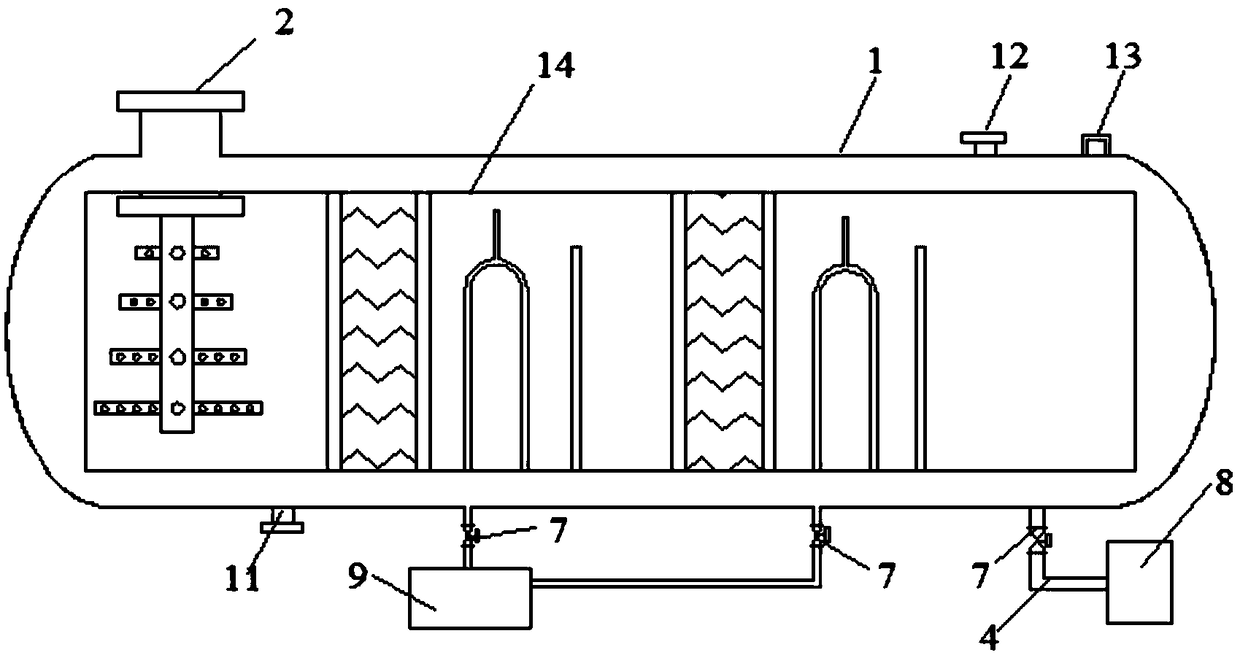

[0024] refer to figure 1 , the embodiment of the present application provides a high-efficiency oil-water phase device, including: a tank body 1, an oil-water feed pipe 2, a water outlet pipe 3, an oil outlet pipe 4, several partitions 5 and several packing chambers 6;

[0025] The oil-water feed pipe 2, the water outlet pipe 3 and the oil outlet pipe 4 are respectively communicated with the tank body 1, and the oil outlet pipe 4 is arranged at an end of the tank body 1 away from the oil-water feed pipe 2 ;

[0026] The filler chamber 6 and the partition plate 5 are arranged at intervals inside the tank body 1, the filler chamber 6 is arranged between the partition plate 5 and the oil-water feed pipe 2, and the water outlet pipe 3 Provided between the packing chamber 6 and the partition 5, the height of the partition 5 is smaller than the inner cavity height of the tank body 1;

[0027] The oil-water feed pipe 2 includes a feed pipe body 21 and an extension pipe 22 communica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap