Pervious concrete mix proportion design method based on paste membrane thickness

A technology of permeable concrete and mixing ratio design, which is applied in chemical instruments and methods, cement mixing devices, clay preparation devices, etc., can solve the problems of unguaranteed performance of permeable concrete, and achieve controllable effective porosity and superior comprehensive performance. , the effect of controllable porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (1) Raw material performance inspection:

[0063] P.O 42.5 ordinary Portland cement is selected, and the indicators all meet the requirements of "Highway Engineering Cement and Cement Concrete Test Regulations" (JTG E30-2005), and the density is 3100kg / m 3 ; Select limestone crushed stone with a single particle size of 4.75-9.5mm as coarse aggregate, "Highway Engineering Aggregate Test Regulations" (JTG E42-2005), and its apparent density is 2700kg / m2. 3 , the bulk density is 1600kg / m 3 , the void ratio is 40.7%; clean tap water is selected, and the density is 1000kg / m 3 .

[0064] (2) Determine the amount of coarse aggregate per unit volume:

[0065] Coarse aggregate dosage per unit volume of permeable concrete m g =α×ρ′ g =0.98×1600=1568kg.

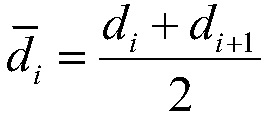

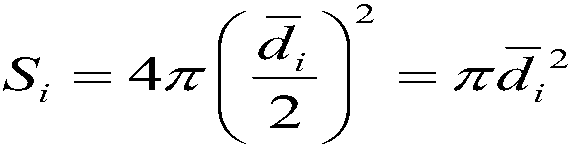

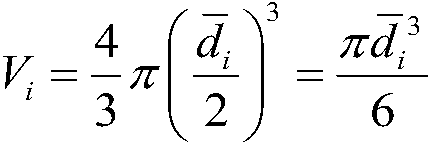

[0066] (3) Calculation of total surface area of coarse aggregate per unit volume:

[0067] The coarse aggregate adopts a single particle size range of 4.75-9.5 mm, and the sieve residual α of the aggregate with this part...

Embodiment 2

[0089] The preset porosity is 23.75%, which corresponds to the film thickness h of 500 μm. Other raw material types and parameters are the same as in Example 1.

[0090] Using the same calculation method as Example 1, the consumption of each raw material was obtained: cement 427.1kg, coarse aggregate 1568kg, water 106.8kg, water reducing agent 0.43kg.

Embodiment 3

[0092] The preset porosity is 20.00%, and the corresponding film thickness h is 350 μm. Other raw material types and parameters are the same as in Example 1.

[0093] Using the same calculation method as Example 1, the consumption of each raw material is obtained: cement 469.8kg, coarse aggregate 1568kg, water 117.4kg, water reducing agent 0.47kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com