Modified silica material suitable for fluorocarbon active agent superamphiphobic debris-carrying agent for water-based drilling fluid, preparation method and application thereof

A silica and modified technology, applied in the field of oil and gas drilling, can solve the problems of complex polymer synthesis process, poor temperature resistance, high product cost, improve drilling speed and wellbore purification efficiency, improve chip carrying effect, The effect of reducing relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

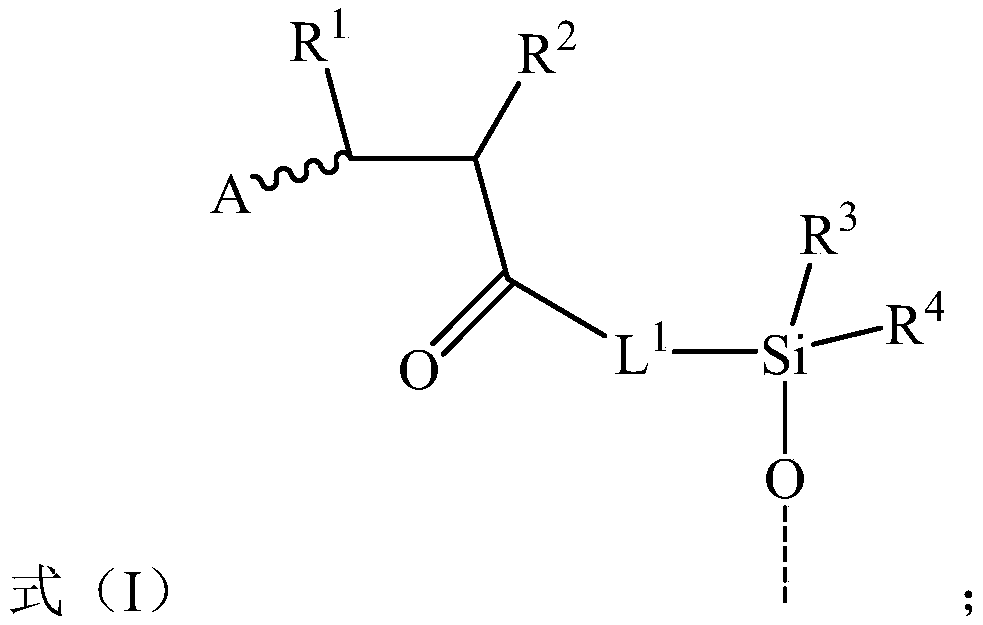

[0024] One aspect of the present invention provides a method for preparing a modified silica material, the method comprising:

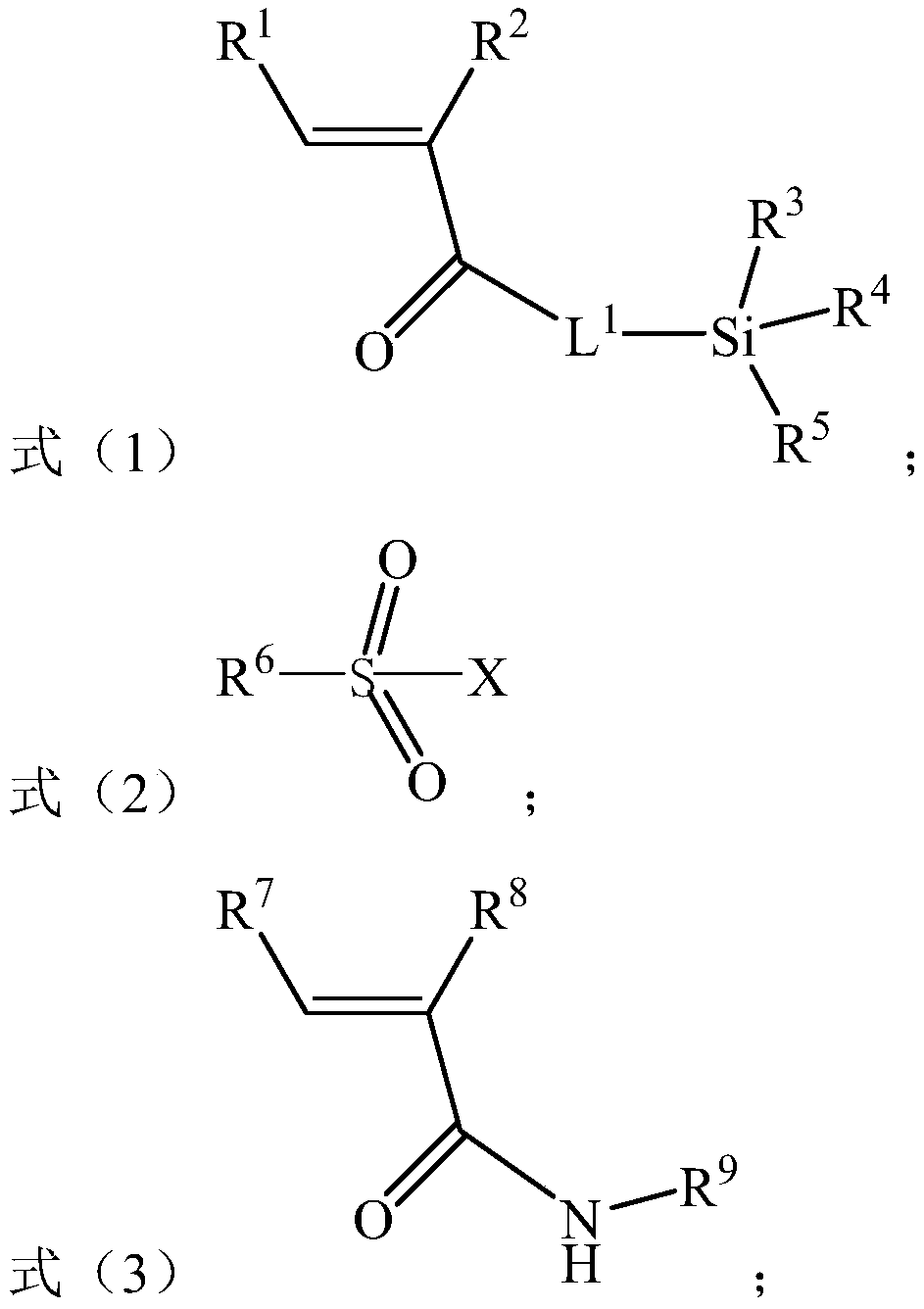

[0025] 1) in a mixed solvent containing alcohol and water, the silica particles and the silane coupling agent represented by the formula (1) are subjected to a first contact reaction;

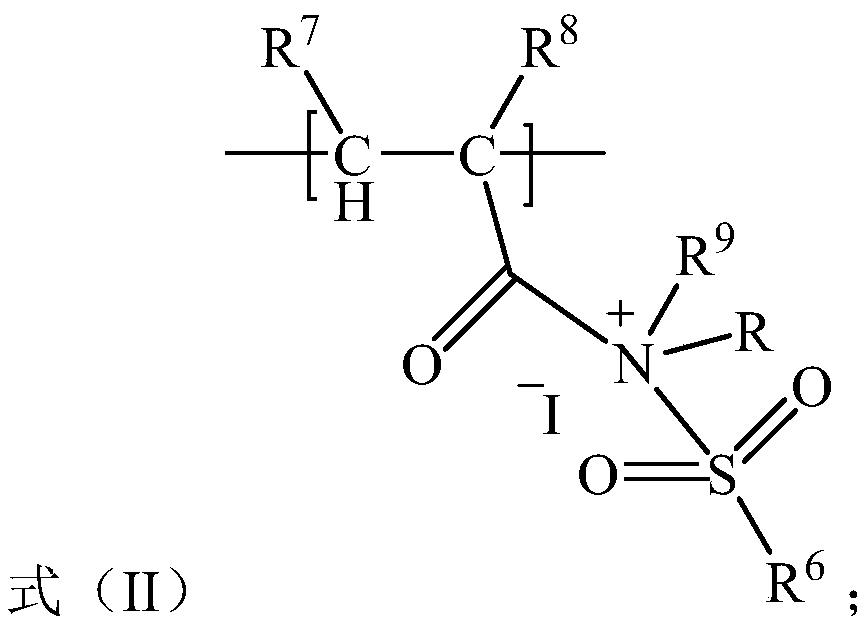

[0026] 2) carrying out the second contact reaction with the product of the first contact reaction with the compound shown in the formula (2) and the compound shown in the formula (3);

[0027] 3) carrying out the third contact reaction with the product of the second contact reaction with the compound shown in formula (4);

[0028]

[0029] Formula (4) I-R;

[0030] R 1 , R 2 , R 7 and R 8 each independently selected from H and C1-C6 alkyl; R 3 -R 5 each independently selected from C1-C6 alkyl and C1-C6 alkoxy; L 1 for -O-L 2 - or C1-C8 alkylene, and L 2 For C1-C8 alkylene; R 6 Perfluoroalkyl selected from C4-C20; R 9 is selected from H or C1-C6 alkyl; R ...

Embodiment 1

[0112] This example is used to illustrate the modified silica material of the present invention and its preparation method.

[0113] In 100mL ethanol-water mixed solution (ethanol / water volume ratio is 1:2), add the silicon dioxide of 1g and ultrasonically disperse 30min; Then add KH570 (wherein, the molar dosage ratio of silicon dioxide in silicon and KH570 is 1 : 0.2) Mix evenly, and raise the temperature to 45°C to react for 60min; then add acrylamide and perfluorooctanesulfonyl fluoride (wherein, the silicon dioxide, acrylamide and perfluorooctanesulfonyl fluoride calculated as silicon The molar ratio of methyl iodide is 1:5:1.5) and continue to react at 45 ° C for 3 hours, and then add methyl iodide after cooling to room temperature (about 25 ° C). ) and reacted for 60min, and the resulting product was the modified silica material FCA-1.

Embodiment 2

[0115] This example is used to illustrate the modified silica material of the present invention and its preparation method.

[0116] Add 1 g of silicon dioxide to 100 mL of ethanol-water mixed solution (methanol / water volume ratio of 1:5) and ultrasonically disperse it for 30 min; then add γ-methacryloyloxypropyl triethoxysilane (wherein, with The molar ratio of silicon dioxide and γ-methacryloyloxypropyltriethoxysilane in terms of silicon is 1:0.3), mix well, and raise the temperature to 60 °C for 90 minutes; then add acrylamide and Perfluorohexylsulfonyl fluoride (wherein, the molar ratio of silicon dioxide, acrylamide and perfluorohexylsulfonyl fluoride in terms of silicon is 1:2:4) and continue to react at 60 ° C for 4 h, and then reduce to room temperature ( About 25°C), add iodoethane (wherein, the molar ratio of iodoethane to acrylamide is 1.5:4) and react for 45min, the obtained product is modified silica material FCA-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com