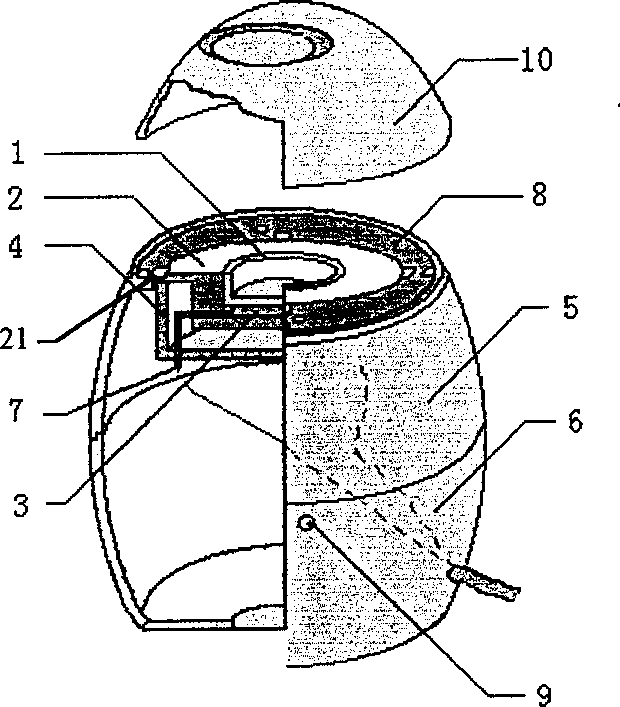

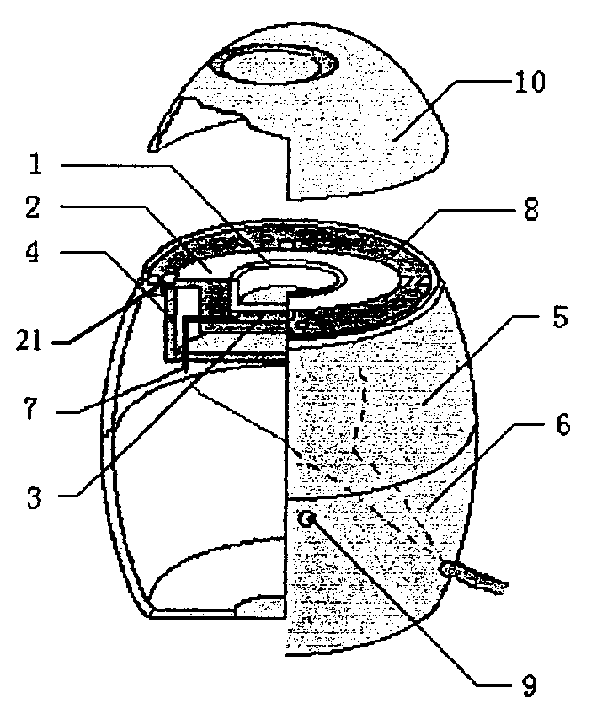

Electroheating fumigating device

A fumigator and electric heating technology, applied in fumigators, devices for capturing or killing insects, applications, etc., can solve the problems of inapplicability, evaporation of pesticides, and few, etc., and achieve the effect of excellent fumigation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Electric strength test and heat insulation test of the electric heating fumigator of the present invention.

[0023] The electric heating fumigator of the present invention is subjected to the electric strength test according to the method stipulated in the national standard GB4706.1.

[0024] The heating temperature of the electric heating fumigator of the present invention is 250°C.

[0025] Pilot projects

Test voltage (volts)

Test time (minutes)

test results

cold electric strength

3750

1

No breakdown or flashover

Electric strength at working temperature

3750

1

No breakdown or flashover

Tidal electric strength

3750

1

No breakdown or flashover

[0026] The heating temperature of the electric fumigator of the present invention is 250° C., and the temperature distribution of each part of the fumigator is shown in Table 2.

[0027] Part Name ...

Embodiment 2

[0029] Laboratory control experiment of Periplaneta americana

[0030] The heating temperature of the electric heating fumigator of the present invention is 250°C. The material of the inner cup is aluminum, the diameter of the inner cup is 20mm, and the height is 8mm. The pyrethroid insecticide is etofenprox, the total amount is 600mg, and the dosage is 15mg / m 3 , medicament volatilization 5mg / min. Test insects: Periplaneta americana. For the test method, refer to the national standard GB13917.3-92. Insecticidal effect test conclusions are given in accordance with national standards GB / T17322.3-1998 and GB / T17322.11-1998.

[0031] Table 3 Number of test insects Repeat times KT 50 95% credible limit of KT 48-hour mortality rate (only) (min) (min) (%) 20 3 52.5 33.6-81.9 100

Embodiment 3

[0033] Laboratory Control Test of Blattella germanica

[0034] The heating temperature of the electric heating fumigator of the present invention is 250°C. The material of the inner cup is aluminum, the diameter of the inner cup is 20mm, and the height is 8mm. The pyrethroid insecticide is etofenprox, the total amount is 600mg, and the dosage is 40mg / m 3 , medicament volatilization 5mg / min. Test insects: German cockroach. For the test method, refer to the national standard GB 13917.3-92. Insecticidal effect test conclusions are given in accordance with national standards GB / T17322.3-1998 and GB / T17322.11-1998.

[0035] Table 4 Number of test insects Dosage Experimental time Knockdown rate Mortality (only) (mg / m 3 ) (hour) (%) (%) 20 40 2 100 -

[0036] 24 - 100

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com