An ultra-high-strength galvanized steel strand for long-span transmission lines

A technology of galvanized steel strands and transmission lines, applied in circuits, power cables, insulated cables, etc., can solve the problems of immature production technology, low strength and poor looseness of production products, and ensure tightness and strong bearing capacity. , The effect of uniform and tight stranding pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

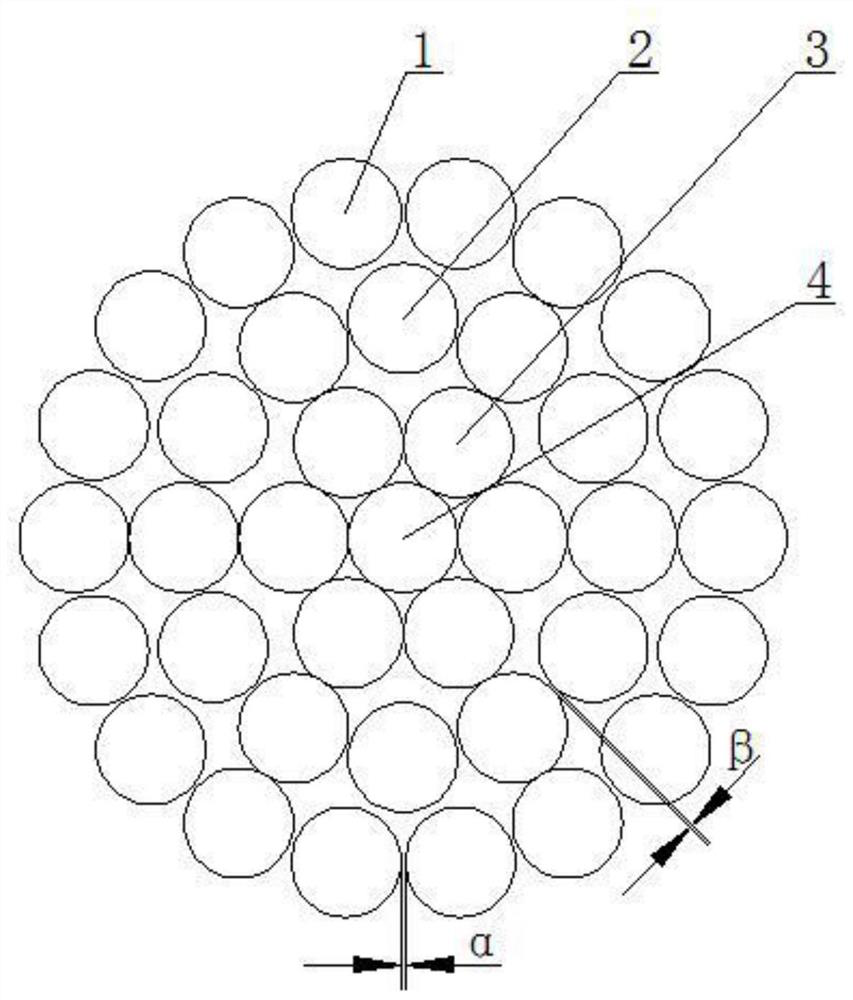

[0017] An ultra-high-strength galvanized steel strand for large-span transmission lines, characterized in that it includes a central wire 4, and an inner layer 3, a middle layer 2, and an outer layer 1 are respectively twisted outside the central wire, and the inner layer is twisted right , the middle layer is left twisted, the outer layer is right twisted; the inner layer is 6 wires, the middle layer is 12 wires, the outer layer is 18 wires, the gap between the inner layer wires is 0, and the gap β between the middle layer wires is not greater than 0.10mm, The gap α between the outer filament and the filament is not more than 0.12mm, and the nominal diameter after twisting is 20.16mm.

[0018] In this embodiment, the tensile strength of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com