Hole forming process of hole bottom chambering device of anchoring hole

A technology for anchoring holes and hole bottoms, which is applied to drilling equipment and methods, drilling equipment, wellbore/well components, etc., which can solve the problems of large anti-floating pile diameters and non-expanding holes, and achieve small drilling diameters and high construction efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

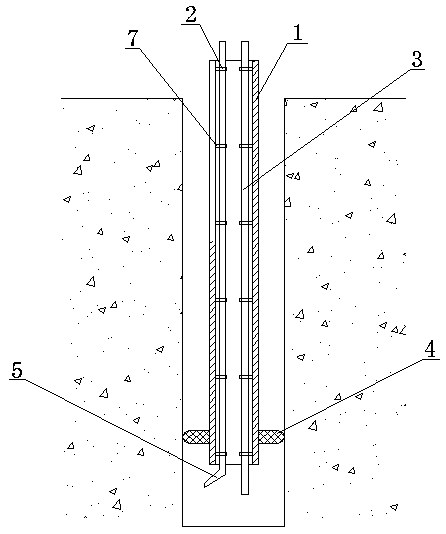

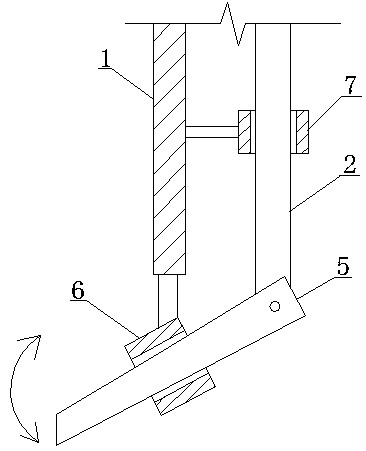

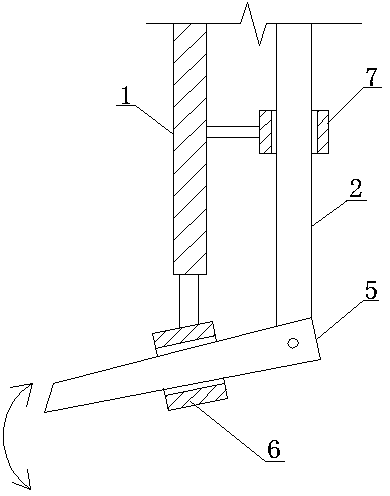

[0014] see Figure 1 to Figure 3 , a hole bottom reaming device for an anchor hole, comprising a rotating sleeve 1, the rotating sleeve 1 is arranged in the anchoring hole, and the rotating sleeve 1 can rotate 360 degrees in the anchoring hole; the rotating sleeve 1 is provided with The water injection conduit 2 and the water extraction conduit 3 are provided with a rubber plug 4 between the outer wall of the lower part of the rotating sleeve 1 and the wall of the anchor hole, and the rubber plug 4 plays a sealing role. The bottom of the water injection conduit 2 is connected with a rotatable water spray pipe 5, the outlet of the water spray pipe 5 is a water spray port, and the water spray pipe 5 is fixed on the rotating sleeve 1 by a rotatable bracket 6, and the water spray pipe 5 Can rotate around water injection conduit 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com