Multifunctional kiln for ceramic and firing process thereof

A multifunctional, ceramic technology, applied in the field of ceramic firing, can solve the problems of low yield and difficult temperature control of firewood kiln, and achieve the effect of high yield, rough and powerful texture, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are used to describe the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

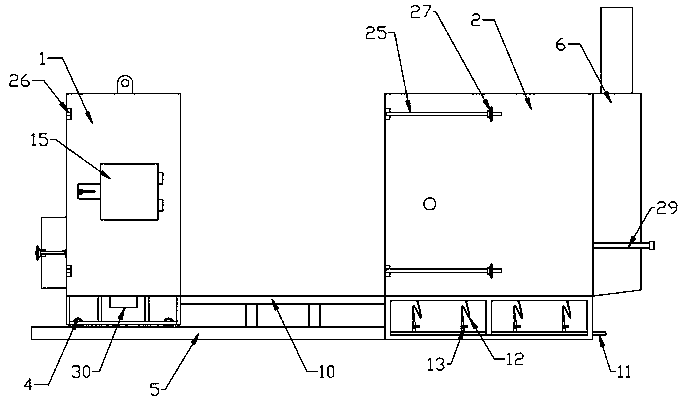

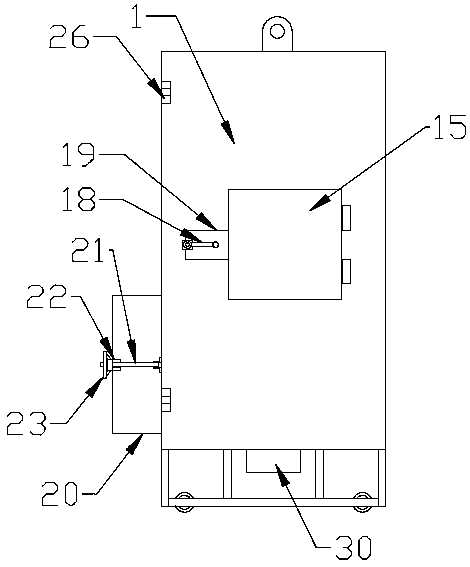

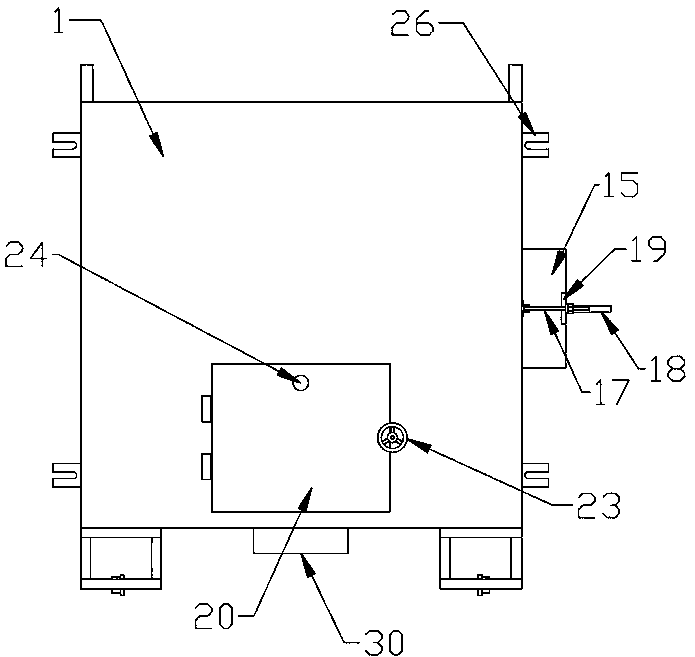

[0033] Such as figure 1 , 4 The multifunctional kiln for ceramics shown in . , the bottom of the burner 1 is provided with a pulley 4 and an ash outlet 30; the outside of the kiln body 2 is provided with a flue 6, and the inside of the kiln body 2 is provided with a kiln chamber 16 communicating with the flue 6, and the flue 6 is provided with a flue The gate plate 29, kiln car 7 is arranged inside the kiln chamber 16, and the top of the kiln car 7 is provided with a laminate 8 through the support column 9. Both sides of the kiln chamber 16 are provided with silicon carbide rods 6 and gas inlets 14 , the bottom of the kiln body 2 is provided with a main gas su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com